Coloring photosensitive resin composition

A technology of photosensitive resin and composition, which is applied in the direction of photosensitive materials, optics, and optical components used in optomechanical equipment, and can solve problems such as insufficient storage stability and thickening of the composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

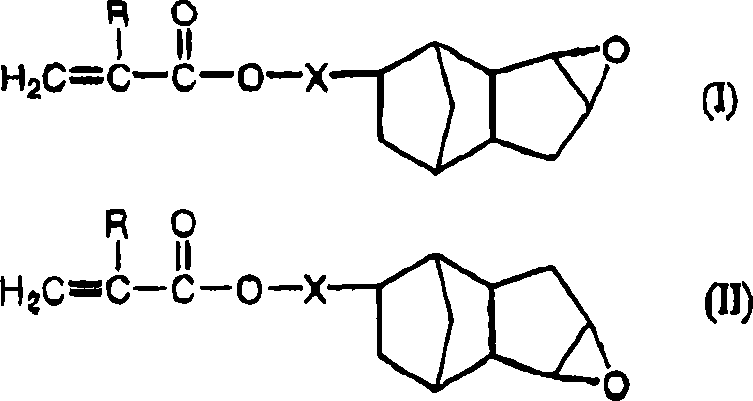

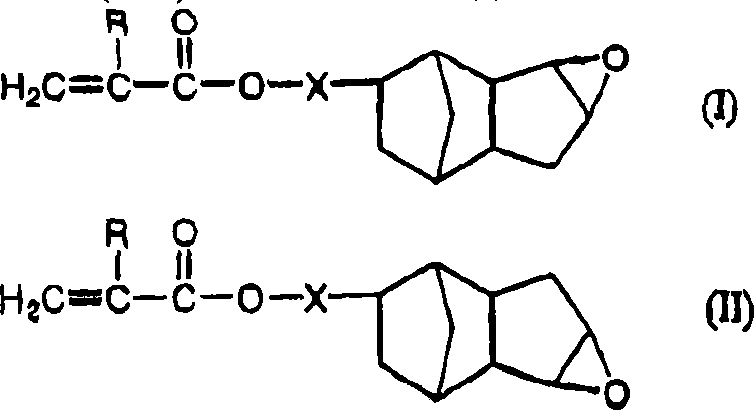

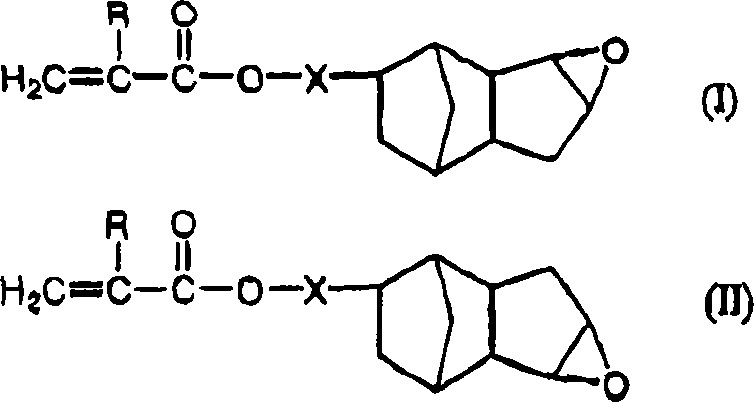

Method used

Image

Examples

Embodiment 1

[0185] The components were mixed into the resin solution part (reduced solid content: 5.172 parts) containing (resin A-1) obtained in Synthesis Example 1 to obtain the compositions shown in Table 1, and a colored photosensitive resin composition was obtained. 1. The storage stability of colored photosensitive resin composition 1 was evaluated, and the results are shown in Table 2.

[0186]

[0187] The colored photosensitive resin composition was stored at 23°C and 40°C for 4 days, and the value obtained by dividing the viscosity of the colored photosensitive resin composition after storage by the viscosity of the composition before storage was expressed in %. Small changes in viscosity are preferred, eg, preferably 98 to 102% at 23°C

[0188] Viscosity: Measured at 23°C and 40°C using a viscosity (VISCOMETER TV-30; manufactured by Toki Sangyo Co., Ltd.).

[0189]

[0190] A 2 inch square glass plate <#1737 manufactured by Corning) was washed sequentially with a neutral ...

Embodiment 2

[0198] Colored photosensitive resin composition 2 was obtained in the same manner as in Example 1 to obtain the compositions shown in Table 1. Table 2 shows the results evaluated in the same manner as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com