Industrial waste gas absorbing recovery device

A technology for adsorption recovery and industrial waste gas, applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve the problems of increased equipment cost and operating cost, large airflow resistance of activated carbon fibers, high production cost and operating cost, etc., to achieve Low cost, large air volume processing, good reliability, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

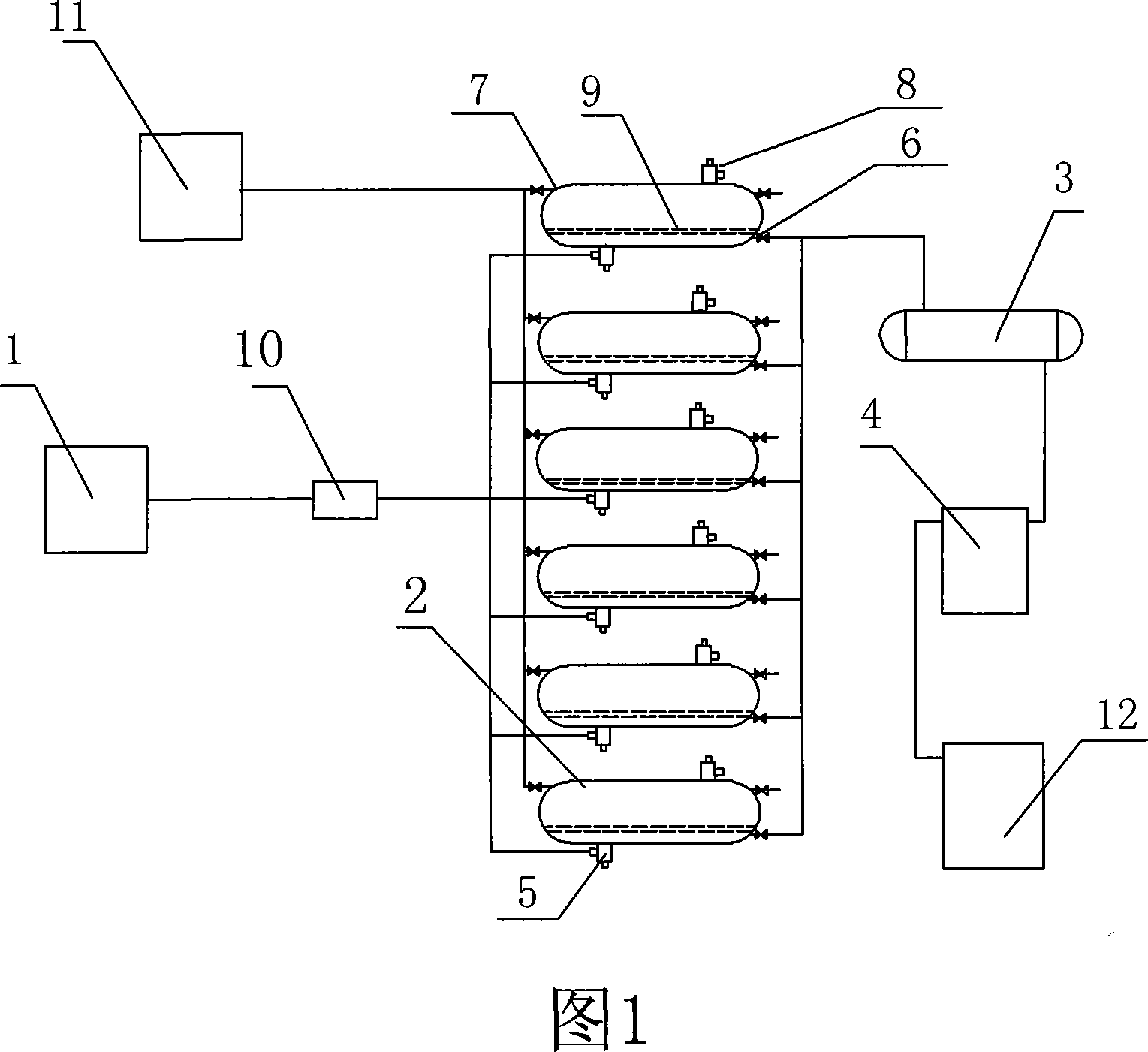

[0015] Referring to Fig. 1, an industrial waste gas adsorption and recovery device includes a gas collection device 1, six adsorption tanks 2, a condenser 3, and a fluid separator 4; the lower part of each adsorption tank is provided with a gas inlet 5, and the bottom is provided with a liquid outlet 6. The top is provided with steam inlet 7 and tail gas discharge port 8 respectively, the gas inlet 5, liquid outlet 6, steam inlet 7 and tail gas discharge port 8 are respectively provided with valves, and the gas collection device 1 is connected to the gas inlet 5. The liquid outlet 6 is connected to the condenser 3, and the condenser 3 is connected to the liquid separator 4; an exhaust gas adsorption device is installed in the adsorption tank 2, and the exhaust gas adsorption device is a carbon bed arranged hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com