Cutting creep instrument

A creep meter and shear box technology, applied in the field of geotechnical engineering, can solve the problems of large volume, deviation of test data, large loading error, etc., and achieve the effects of good mechanism flexibility, high test accuracy and stable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

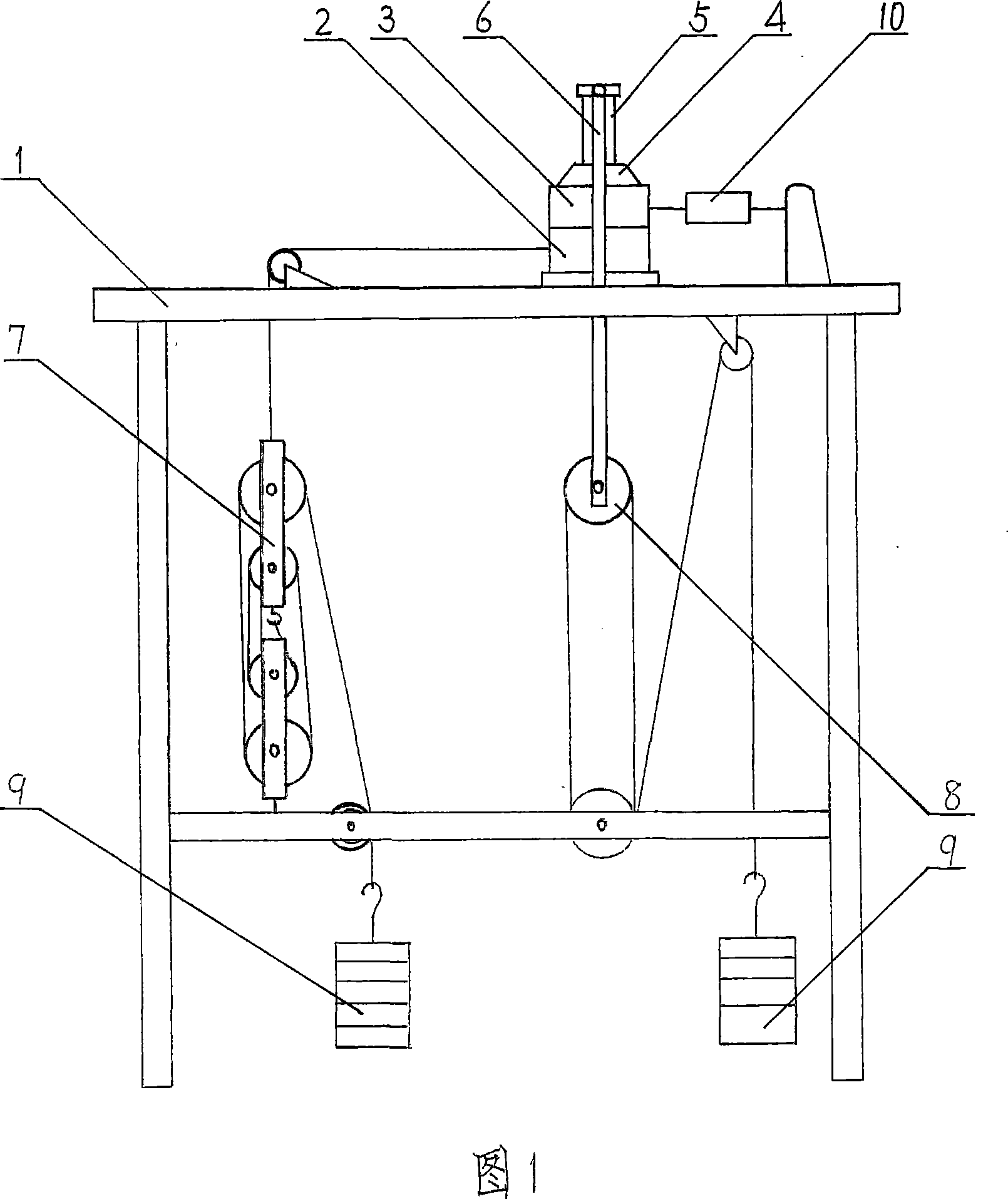

[0010] As shown in Fig. 1, the present invention comprises test bench 1, is positioned at test bench 1 and is provided with the shear box that is made up of lower shear box 2 and upper shear box 3, and the top of described shear box is provided with pressure-bearing cover 4. A pressure sensor 5 is provided on the pressure-bearing cover 4, and one side of the upper shear box 3 is connected to the tension sensor 10; the pressure sensor 5 is connected to the vertical pressure loading pulley block 8 through the force transmission frame 6; the lower shear box 2 The traction rope is connected with the horizontal shear force loading pulley block 7;

[0011] The shear box is square.

[0012] The vertical pressure loading pulley set 8 , the horizontal shear loading pulley set 7 and the weight 9 are all arranged under the test bench 1 .

[0013] Both the vertical pressure load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com