A standard temperature control device

A temperature control device and etalon technology, applied in the field of lasers, can solve the problems of uneven heating on the surface of the etalon, difficulty in laser resonator cavity, and inability to control the etalon, etc., and achieve the effects of compact structure, uniform heating, and high temperature control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

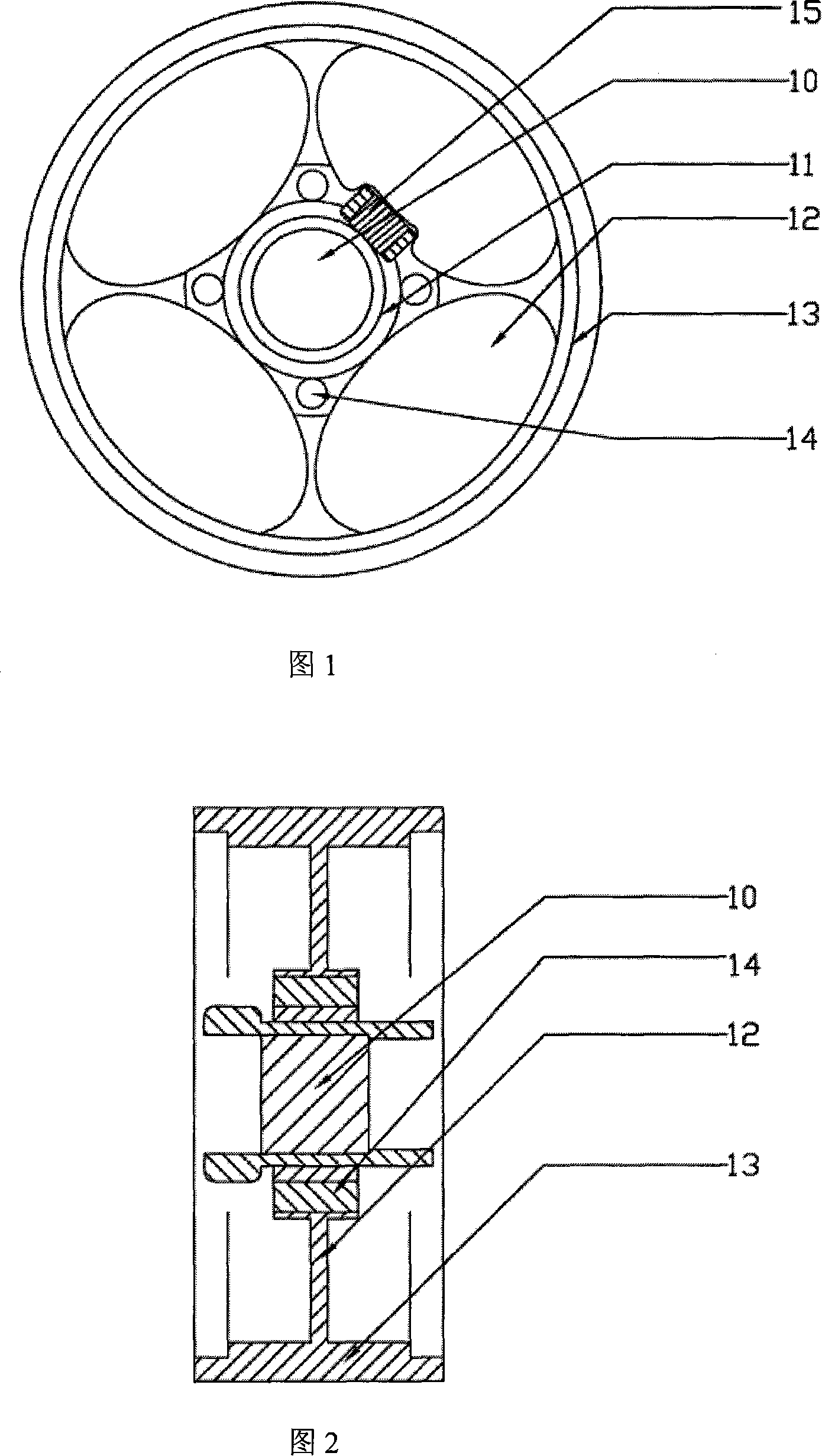

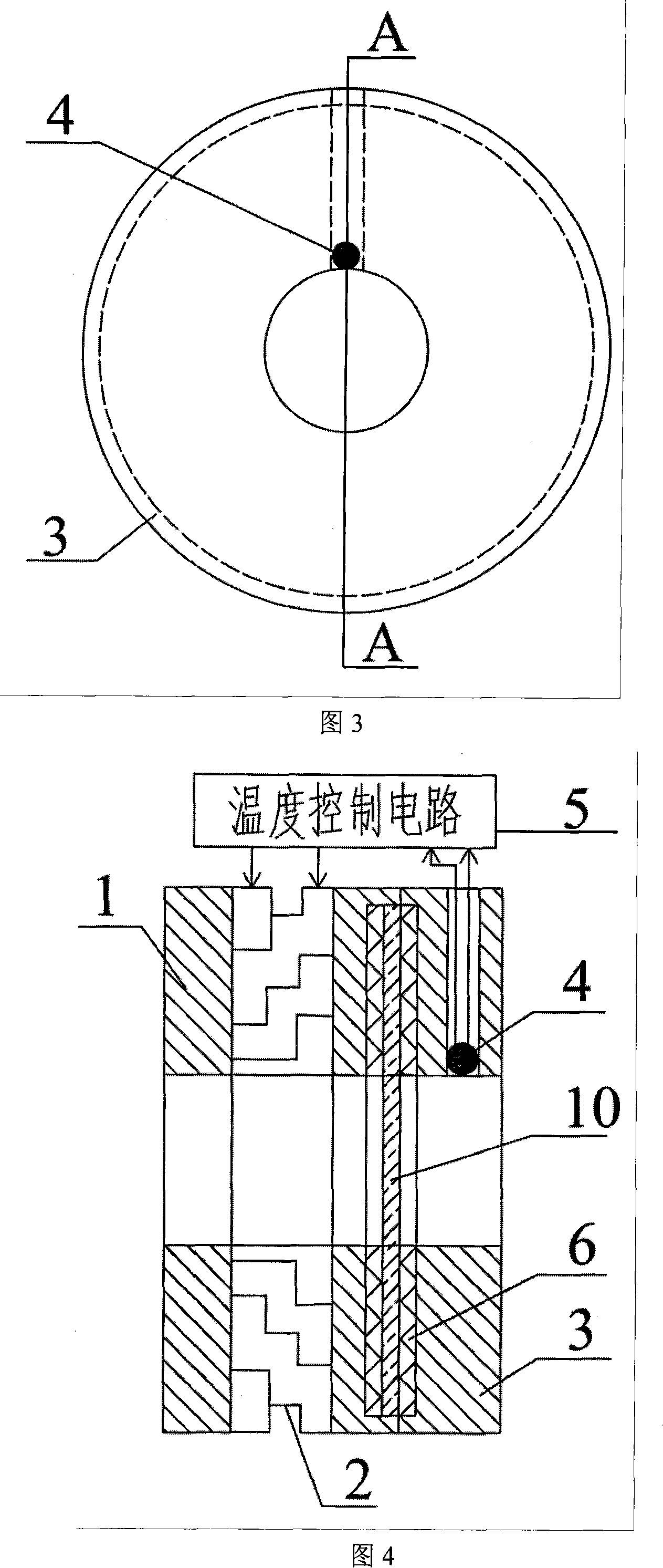

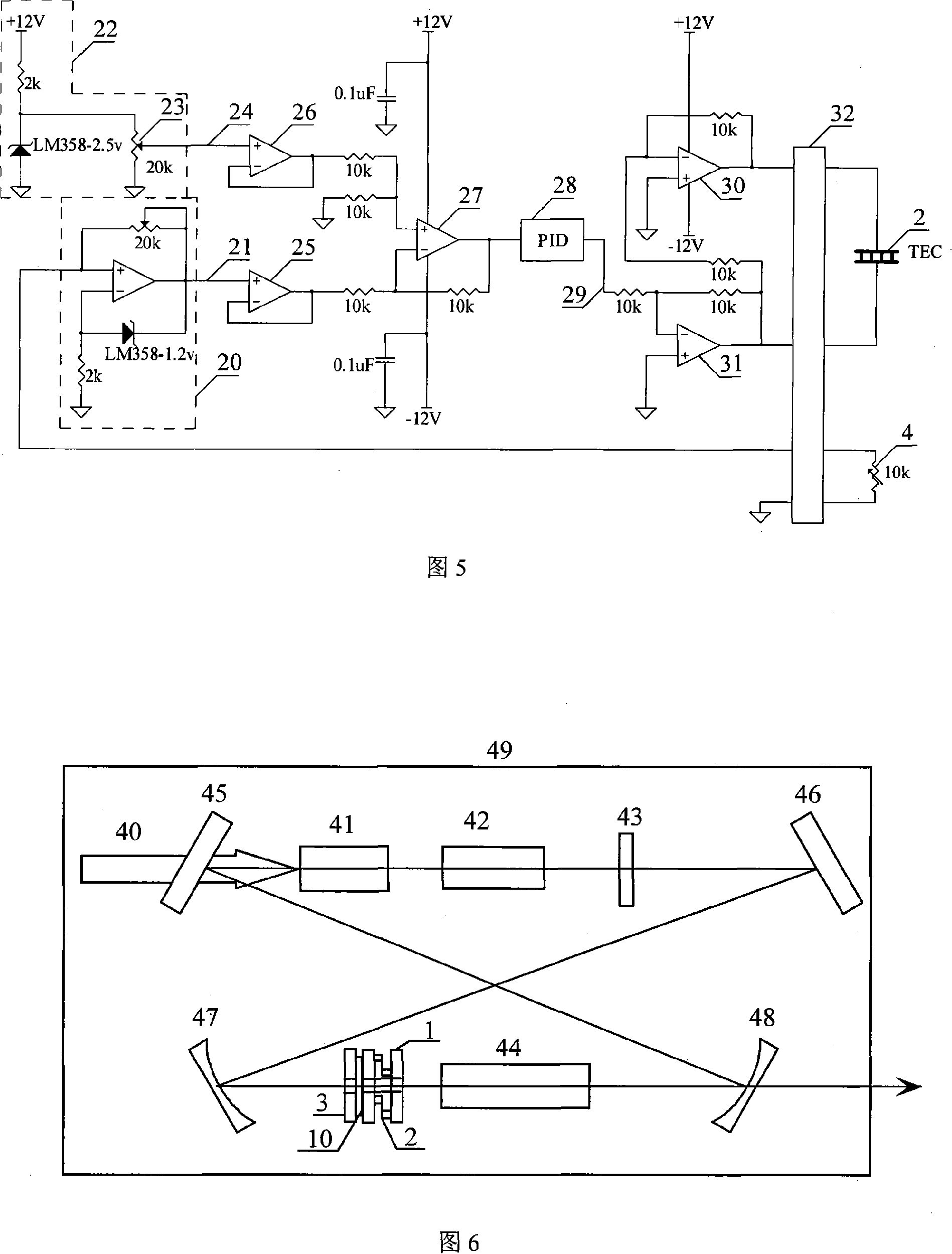

[0029] Fig. 3 and Fig. 4 are schematic diagrams and cross-sectional views of the etalon temperature control device of the present invention. In the figure, the etalon 10 is made of K9 glass with two light-transmitting surfaces parallel to each other, and the size of the etalon 10 is φ15×0.5mm . The ring-shaped indium foil 6 with an inner diameter of 5 mm and an outer diameter of 15 mm is placed on the two transparent surfaces of the etalon 10 respectively, and placed in the controlled unit 3 . The controlled unit 3 is composed of two pieces of copper material, and a concave surface with a size equivalent to the etalon 10 is formed on the contact surface of the two pieces of copper, and the etalon 10 and the indium foil 6 are placed in the concave surface. A thermistor with a negative temperature coefficient is installed inside the controlled unit 3 as a sensor 4, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com