Installing and soldering technique of inlet, outlet slip ring of large-scale sliding crawler mill barrel

A process method and slip ring technology, applied in the direction of manufacturing tools, welding equipment, welding accessories, etc., can solve the problems of high technical requirements, high production cost, steel plate thickness, etc., and achieve the effect of strong operability and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

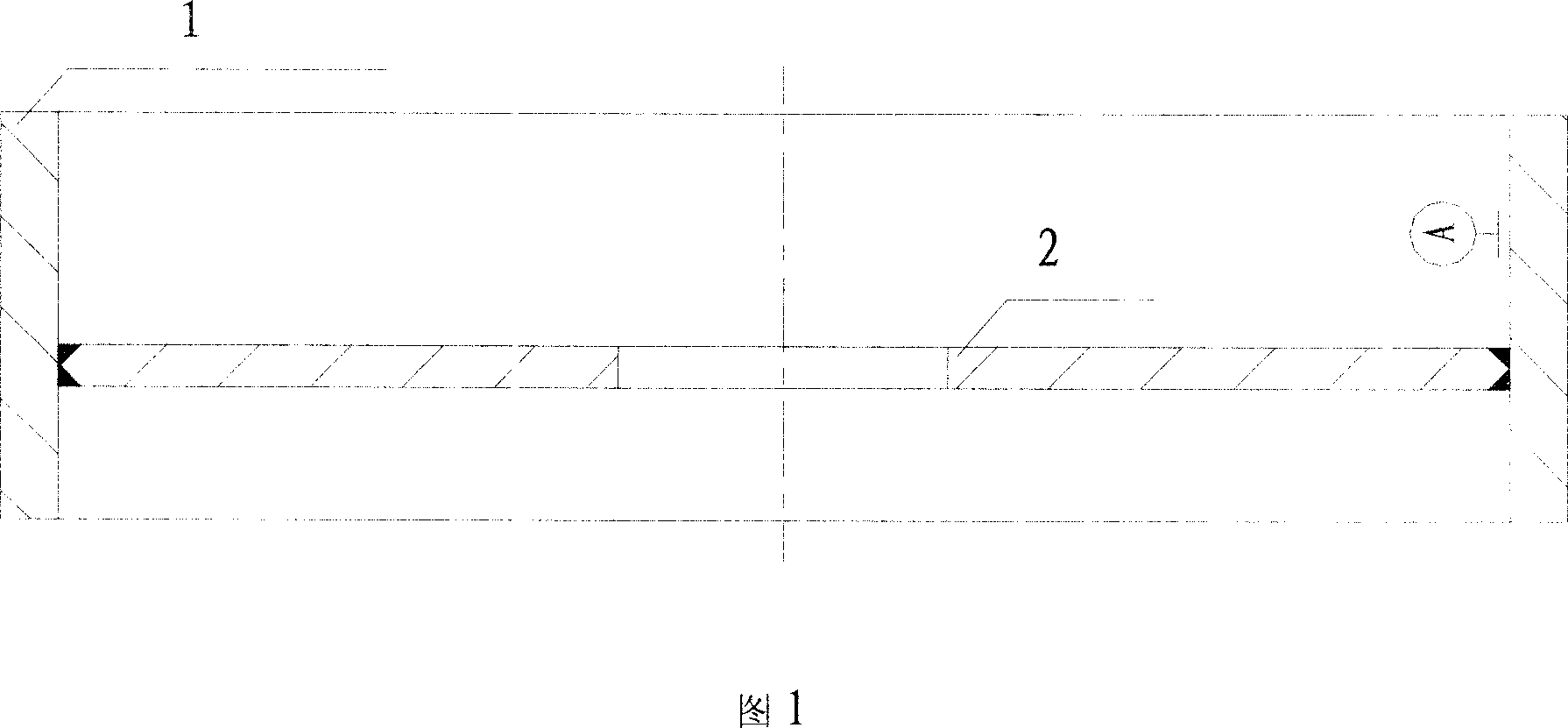

[0034] As shown in Figure 1, the assembly and welding process of the inlet and outlet slip rings of the large-scale sliding shoe grinding cylinder, the specific manufacturing and assembly process is as follows:

[0035] 1. Use numerical control method to cut the motor vehicle to blank the blank of the web. The web (2) is spliced by two pieces. When blanking, leave a machining allowance of 15mm for the outer circle, cut and grind the groove, and bring out the leading and arc extinguishing plates .

[0036] 2. The two spliced webs (2) are welded by submerged arc automatic welding. During welding, the root is cleaned from the reverse side. During the welding process, it needs to be turned over many times to control the welding deformation and correct after welding. The flatness should not be greater than 3mm. Press Drawings require ultrasonic inspection of welds.

[0037] 3. Mark the reference line on the welded web (2) for reference during assembly, so that the joints with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com