Buoyant device used for blowout preventer in deepwater drilling water

A technology of deepwater drilling and buoyancy devices, which is applied in earthwork drilling, wellbore/well components, sealing/isolation, etc. It can solve the problems of time-consuming installation of buoys, the ABS system cannot bear the flow rate, and water depth limitations, etc., to achieve improved stability Performance and adaptability, convenient underwater operation, and reduced installation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

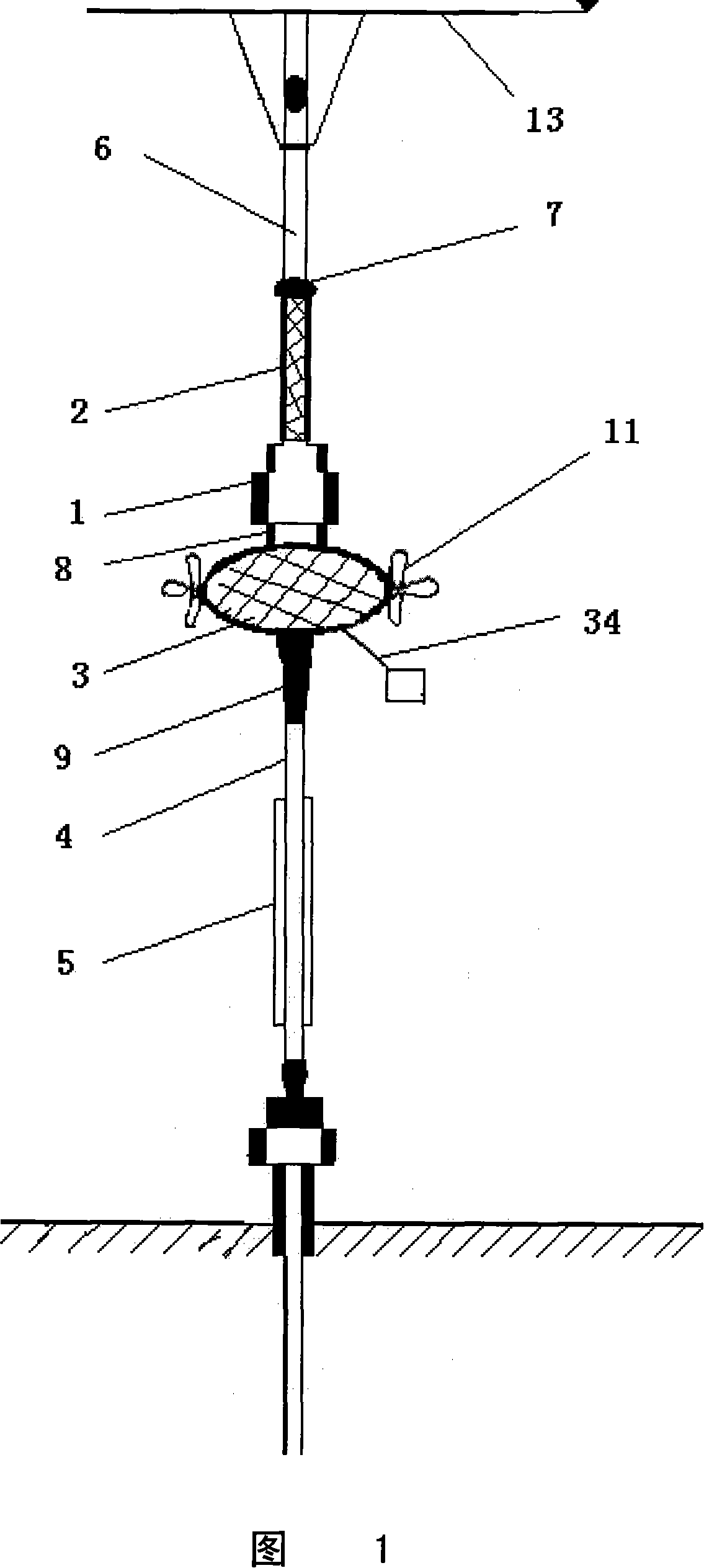

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

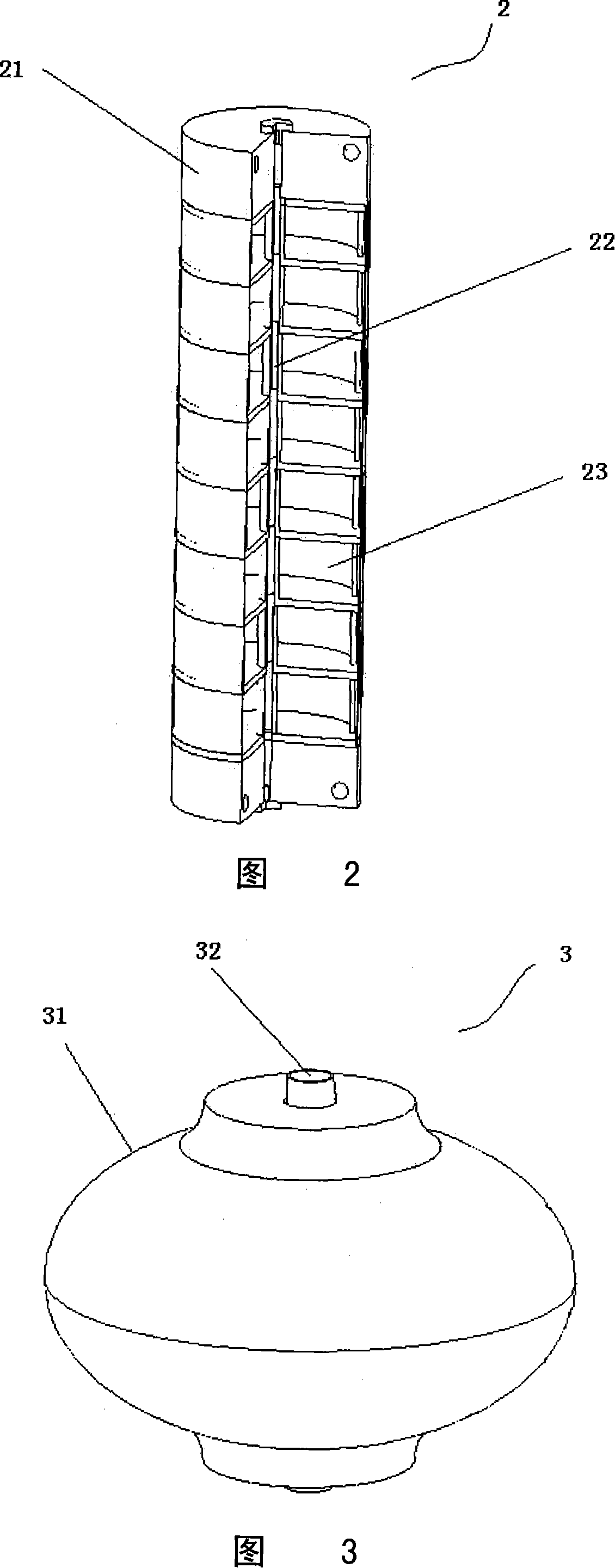

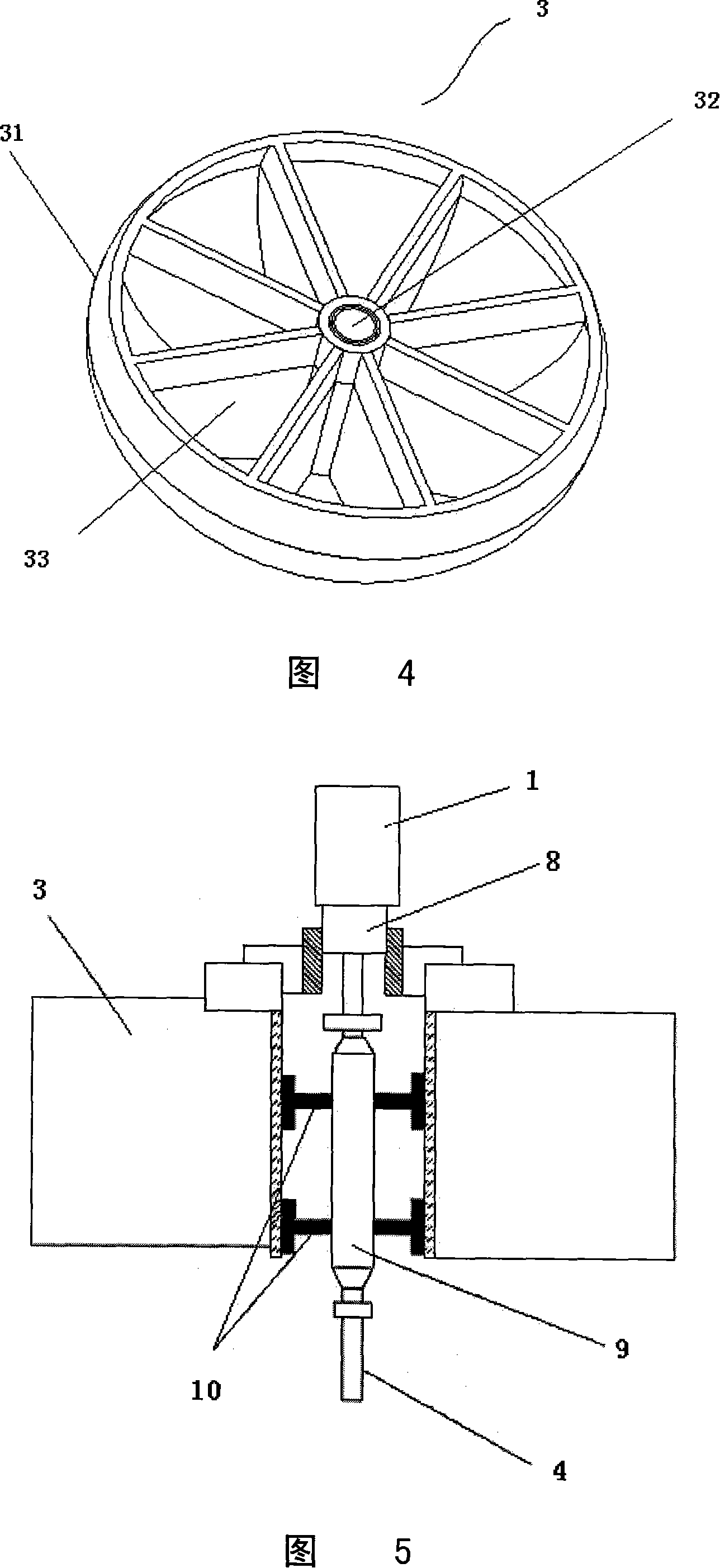

[0028] As shown in Fig. 1 and Fig. 2, the present invention includes a blowout preventer 1 arranged at 80 to 100 meters below the water surface, a buoyancy chamber 2 connected to the top of the blowout preventer 1 as an upper buoy, and a buoyancy chamber 2 connected to the blowout preventer 1 A ballast tank 3 with the bottom as the lower buoy, a high-pressure riser 4 connected to the bottom of the ballast tank 3 and a buoyancy block 5 arranged outside the high-pressure riser 4 . The buoyancy chamber 2 and the ballast chamber 3 as the upper and lower buoys can effectively reduce the center of gravity of the blowout preventer 1 in the entire drilling device, thereby improving the stability and adaptability of the entire drilling device and expanding the operating window of the drilling system , and at the same time can achieve the purpose of reducing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com