Multi-layer oil tube for coextrusion vehicle

A co-extrusion, automotive pipeline technology, applied in the direction of pipes, rigid pipes, layered products, etc., can solve problems such as decreased fuel leakage performance, unfavorable to reduce hydrocarbon emissions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The application will be further described below in conjunction with the accompanying drawings.

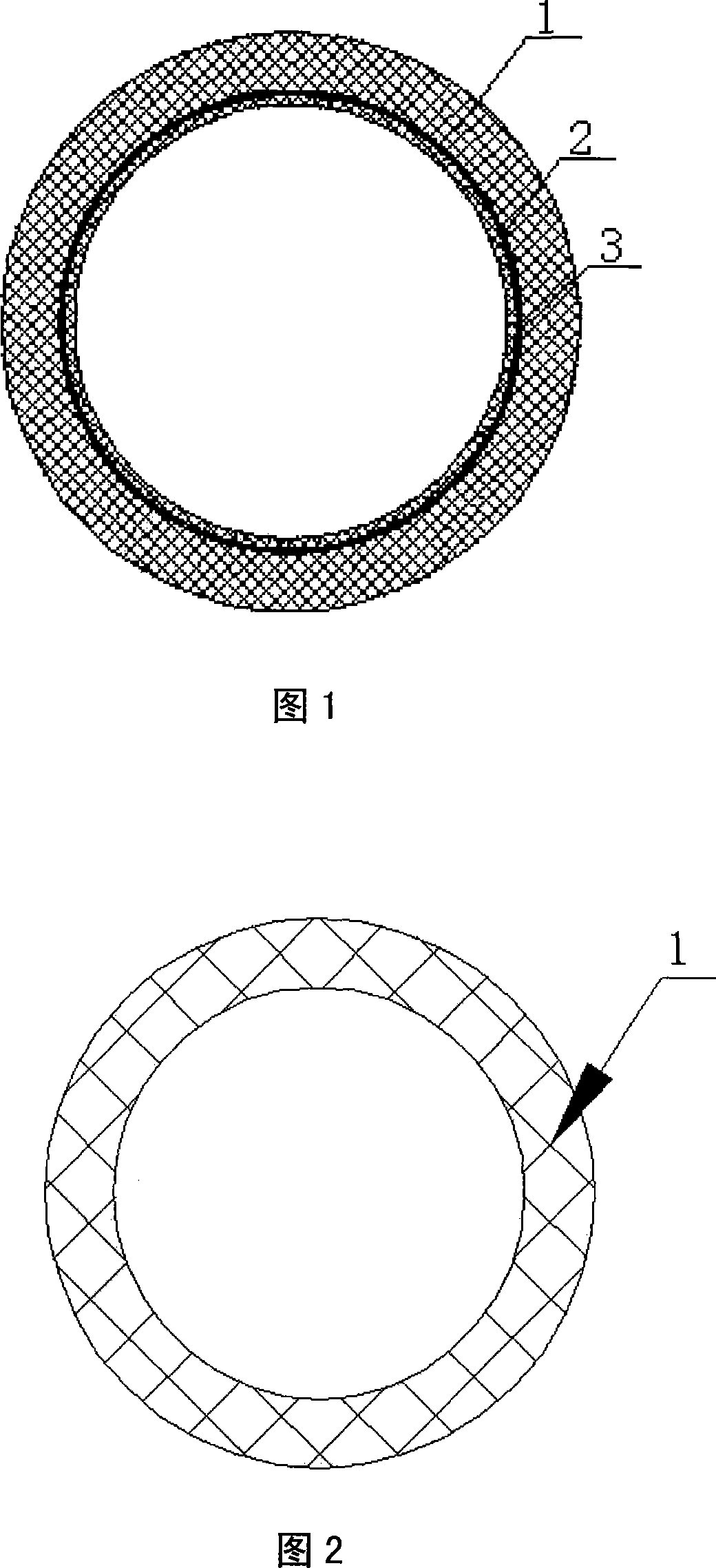

[0010] Figure 1 shows a cross-sectional schematic diagram of an automobile pipeline made by co-extrusion, in which polyamide 612 is used for the outer layer, its long-term working temperature can reach 150 ° C, and the peak temperature can reach 180 ° C, which can be applied to the engine compartment and other high temperature environment areas. The use of polyvinylidene fluoride in the inner layer can effectively inhibit the leakage of hydrocarbons from the molecular gap and reduce the emission of hydrocarbons; compared with polyamide as the inner layer, it is not easy to use polyvinylidene fluoride in the inner layer Polar components (alcohols) react and are more suitable for alcohol-containing fuels. An intermediate layer of adhesive bonds the inner and outer layers together.

[0011] The total wall thickness of the automobile pipeline is 0.9-1.1mm, preferably 1.0mm. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com