Method for monitoring ferromagnetic material fatigue crack expansion by variated magnetic signal

A technology of fatigue crack growth and ferromagnetic materials, applied in the direction of analyzing materials, material magnetic variables, measuring devices, etc., can solve problems such as inapplicability, and achieve the effects of simple operation, accurate detection results and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. In a specific embodiment, the material of the component is 18CrNiWA steel.

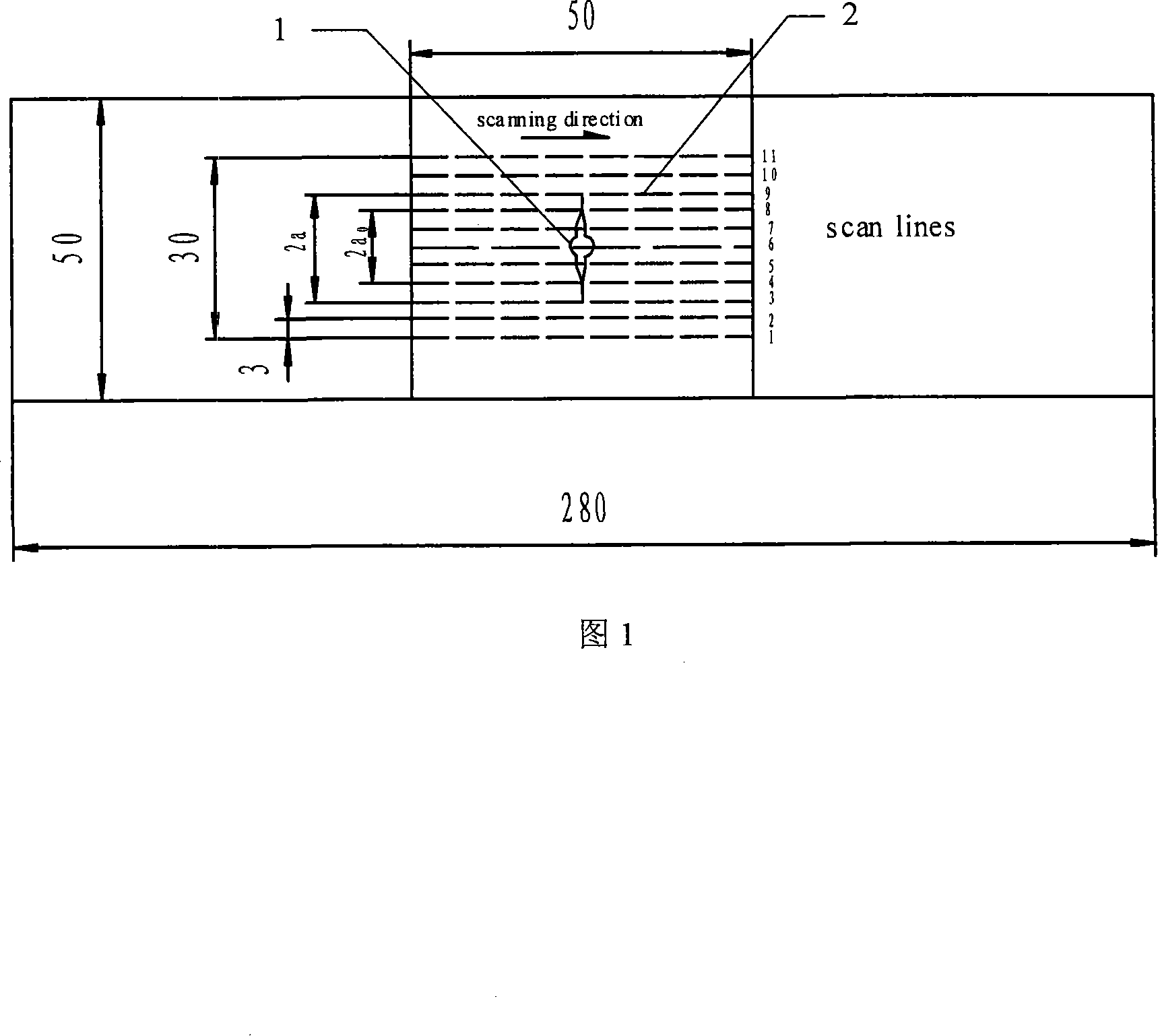

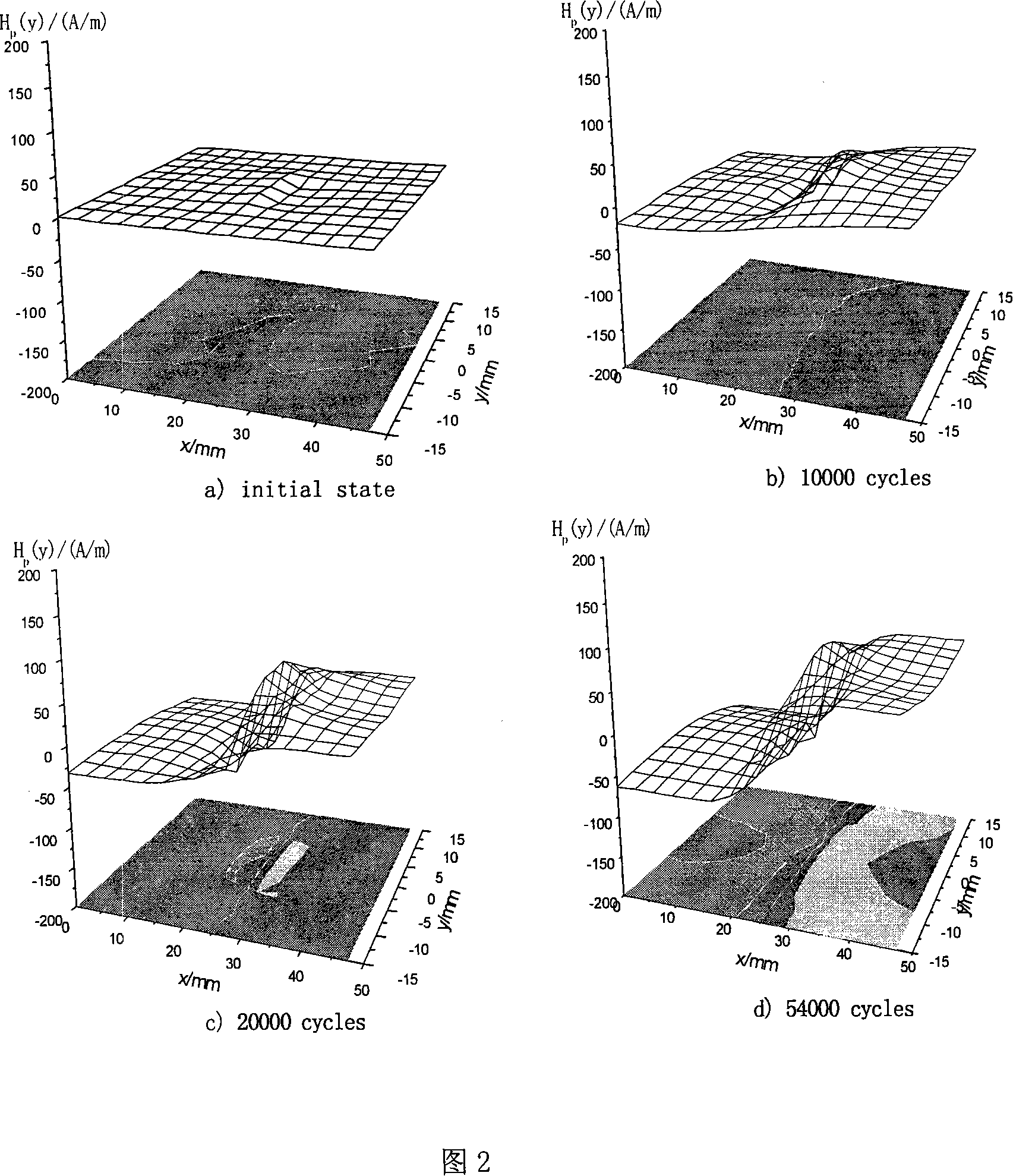

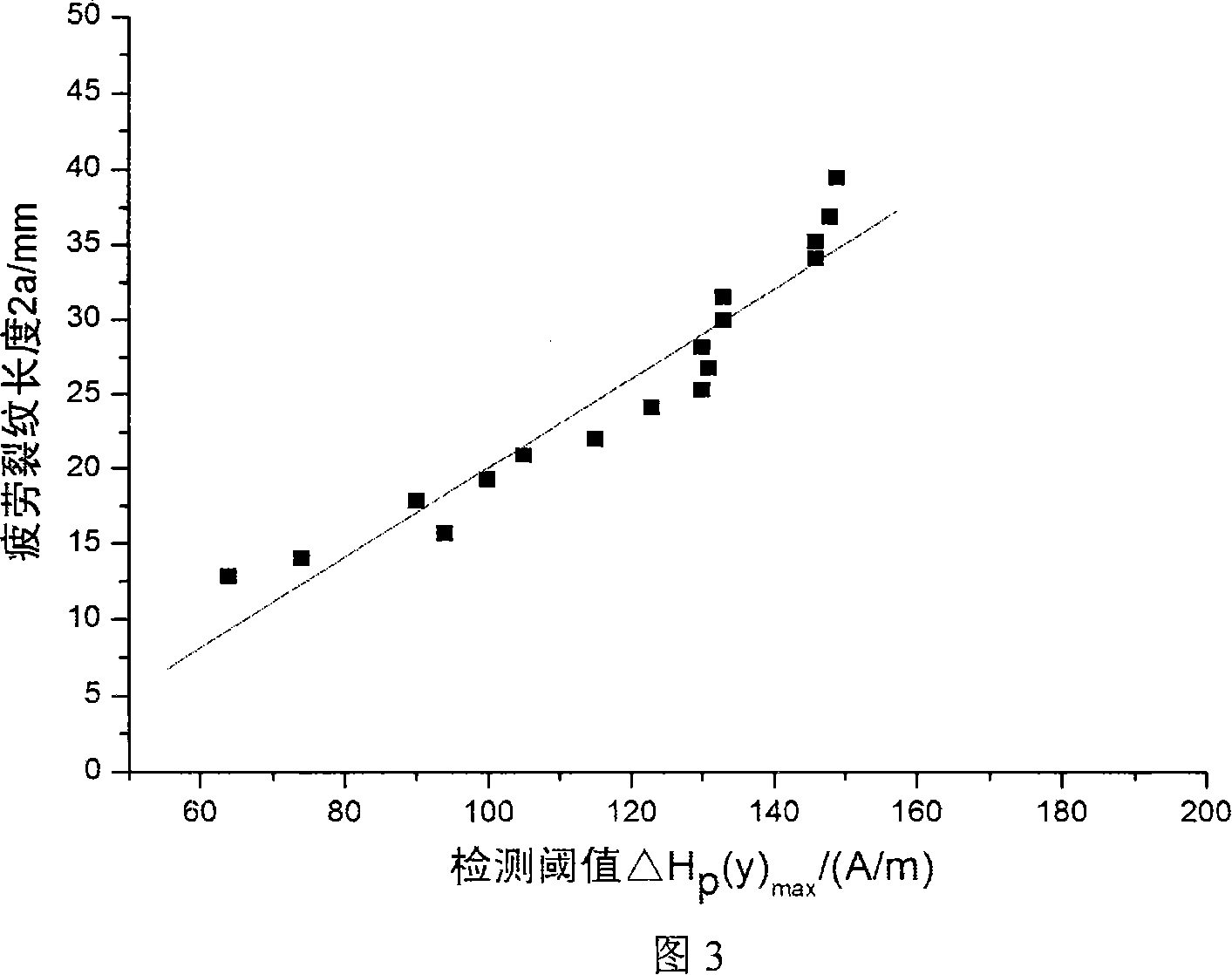

[0025] Firstly, the ferromagnetic material 18CrNiWA steel, which is the same as the material of the tested component, is selected, and a plate-shaped standard tensile test piece with a central penetration crack is made according to the national standard GB / T6398-2000. The prefabricated central crack is processed by wire cutting technology, the original length is 2a 0 =12mm (as shown in Figure 1). Carry out final heat treatment on the standard sample according to the heat treatment specification of the tested component, in a vacuum of 8×10 -1 Heat to 860°C in Pa WZC-30 type vacuum heat treatment furnace, keep warm for 30 minutes, oil quench, then temper at 180°C, and water cool to room temperature. To obtain a pure initial magnetic state on the surface of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com