Gas light-emitting diode

A light-emitting diode and gas technology, which is applied in the field of gas light-emitting diodes, can solve problems such as difficulty in increasing the power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

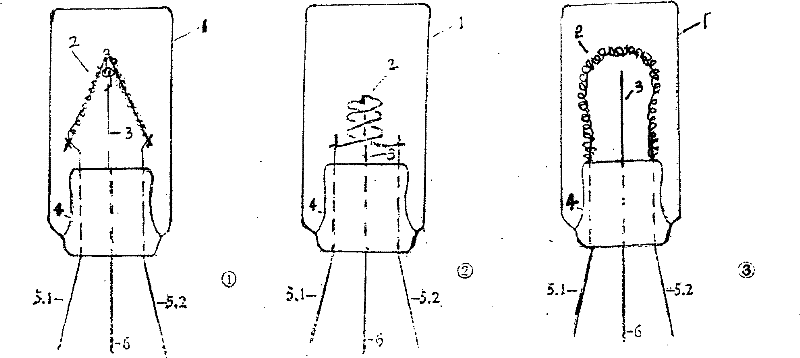

[0011] Embodiment 1 image 3 - In ①: the cathode spiral 2 is a Λ (rumda) structure; the diameter of the anode rod 3 is 0.6-0.9 mm.

Embodiment 2

[0012] Example two attached image 3 - In ②, the cathode spiral 2 is a Θ (Stether) structure with an inner diameter of 6 mm, a spiral length of 9 mm, and 3 to 5 turns of the spiral; the diameter of the anode rod is 0.6 to 0.9 mm.

Embodiment 3

[0013] Embodiment Three Attachment image 3 — In ③ middle: the cathode spiral 2 is an omega (omega) structure; the diameter of the anode rod 3 is 0.6-0.9 mm.

[0014] The anode rod, the cathode spiral and the core post form the wick; the wick and the glass envelope are then sealed to the GLED of the invention.

[0015] will attach image 3 - The cathode outer guide wire 5.1 and 5.2 in ①②③ are combined and then connected to the negative pole of the power supply, and the anode outer guide wire 6 is connected to the positive pole of the power supply. The cathode and anode in the lamp form a positive corona discharge system and a hollow cathode discharge system.

[0016] Beneficial effect

[0017] 1. Positive resistance discharge There are many forms of discharge. The current technology commonly used is positive column discharge; positive column discharge is based on parallel electrodes and a uniform electric field, showing negative resistance characteristics.

[0018] The dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com