Method for integrating insulation film between fluorine doped silicon oxide glass layers

A technology of interlayer insulating film and silicon oxyfluoride, which is applied in the manufacture of electrical components, electric solid-state devices, semiconductor/solid-state devices, etc. The effect of meeting electrical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

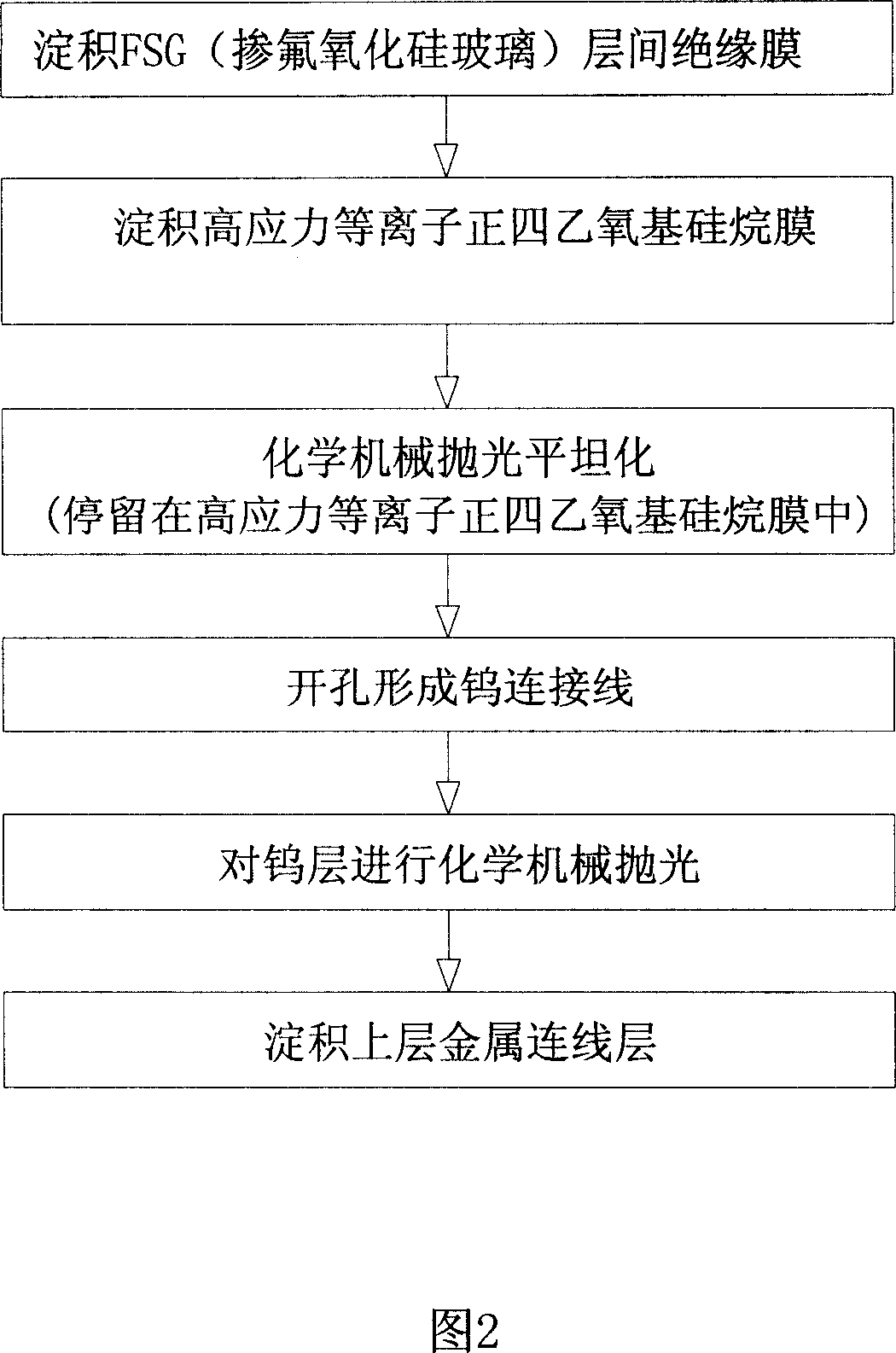

[0011] As shown in Figure 2, the integration method of the fluorine-doped silica glass interlayer insulating film of the present invention comprises the following steps: Step 1, depositing fluorine-doped silica glass (FSG) interlayer insulating film; Step 2, depositing stress Plasma positive tetraethoxysilane film in the range of -250MPa to -600MPa; Step 3, chemical mechanical polishing planarization; Step 4, opening holes to form tungsten connecting lines; Step 5, performing chemical mechanical polishing on the tungsten layer; Step 6, depositing Build up the upper metal wiring layer.

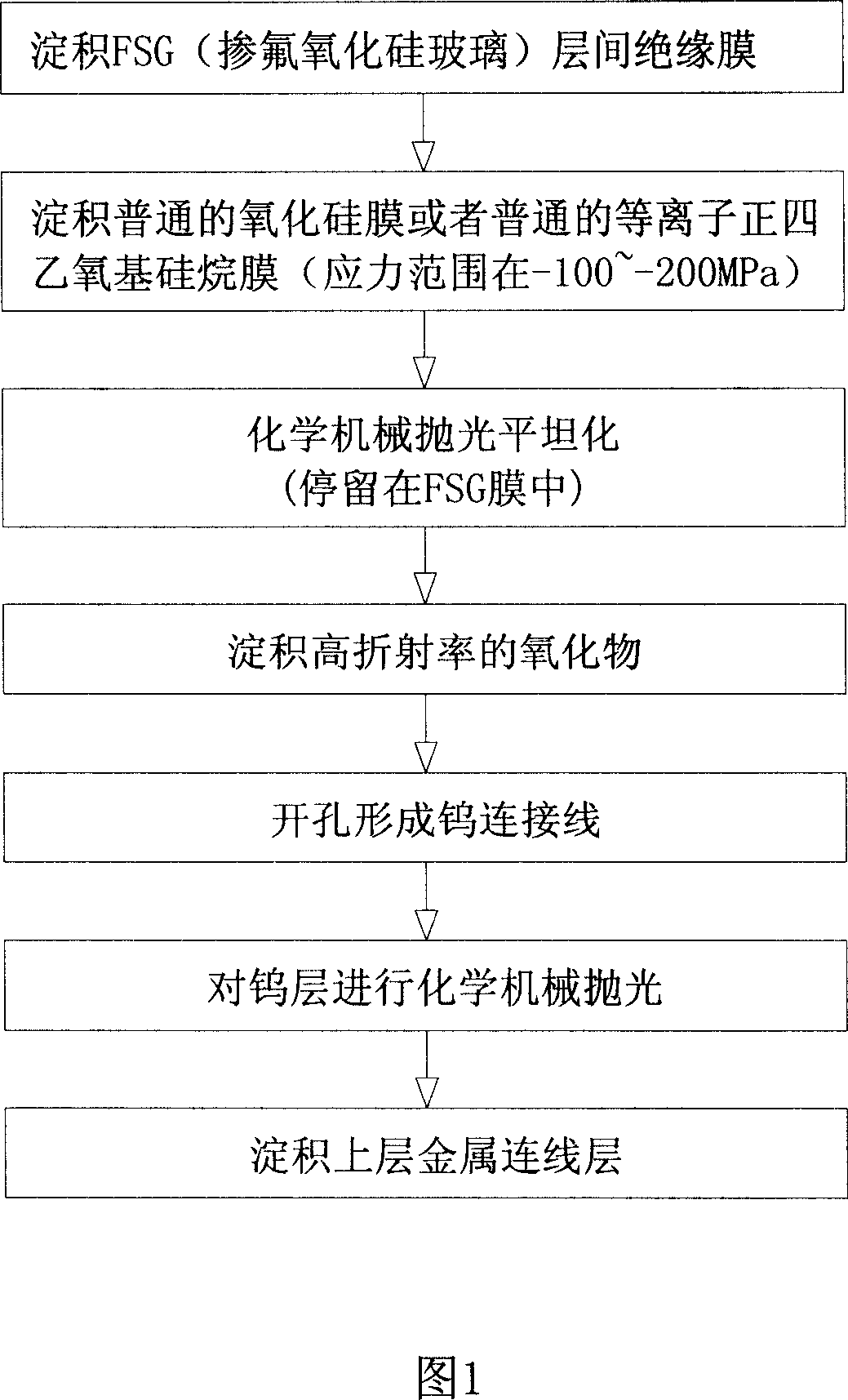

[0012] Different from the prior art shown in FIG. 1, the method provided by the present invention directly deposits a high-stress plasma n-tetraethoxysilane film after depositing FSG to achieve the purpose of binding free radicals of fluorine. Membrane stress reaches -250MPa ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com