Steel strip substrate MH-Ni buckle type rechargeable battery

A technology of steel strip substrate and rechargeable battery, applied in nickel batteries, alkaline batteries and other directions, can solve the problem of easy powder removal, and achieve the effect of improving cycle life, reducing cost and small internal resistance of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

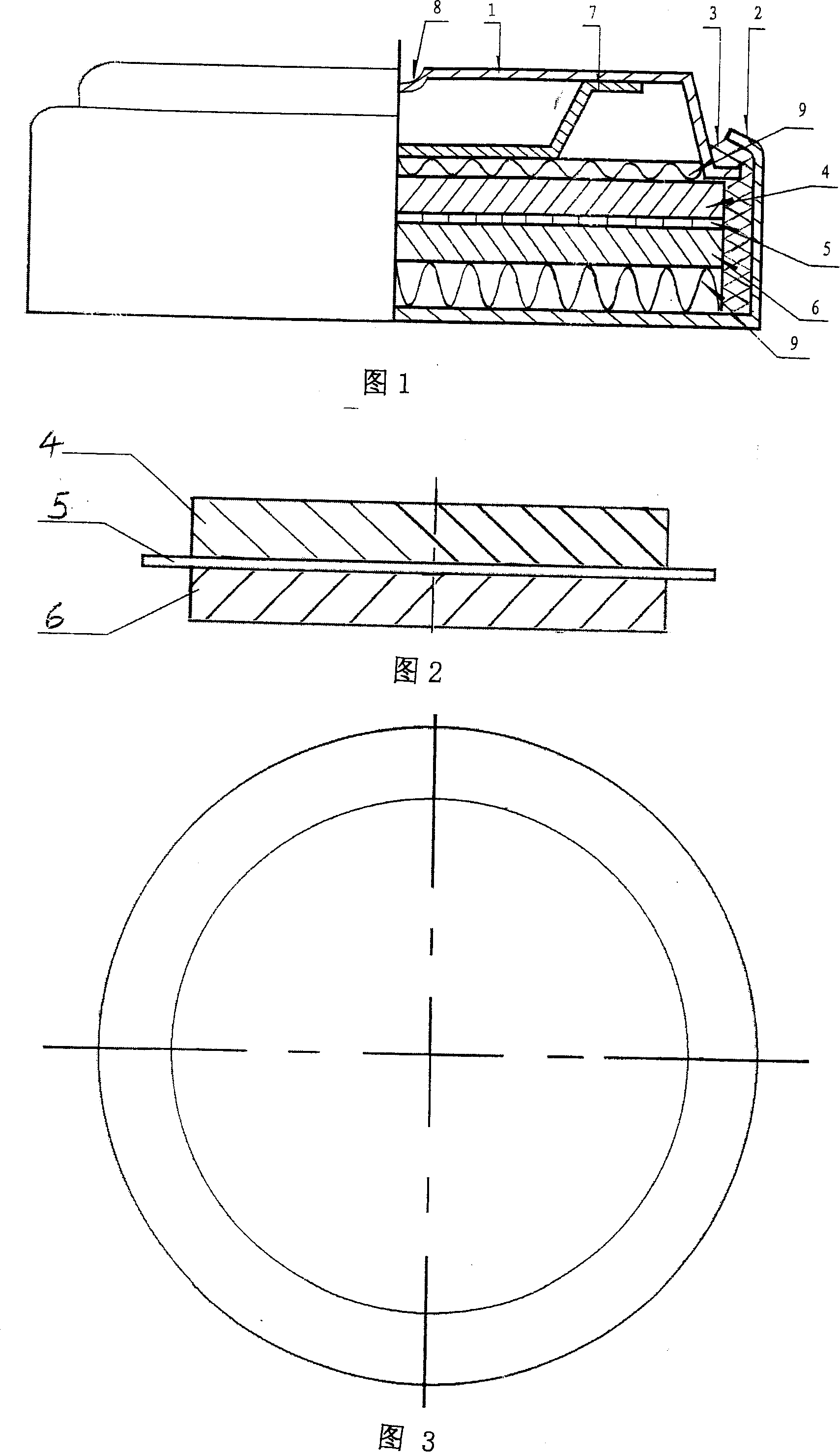

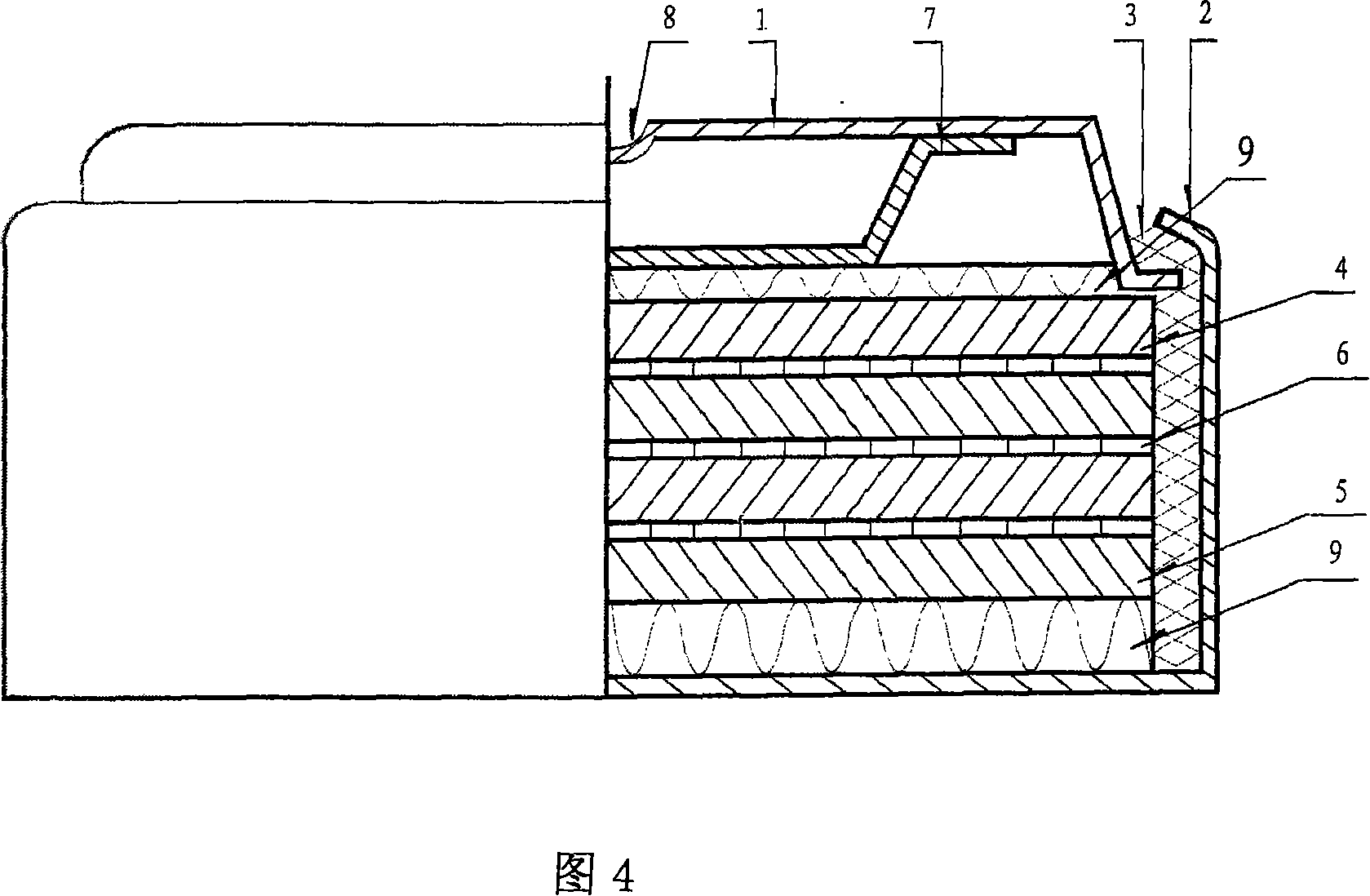

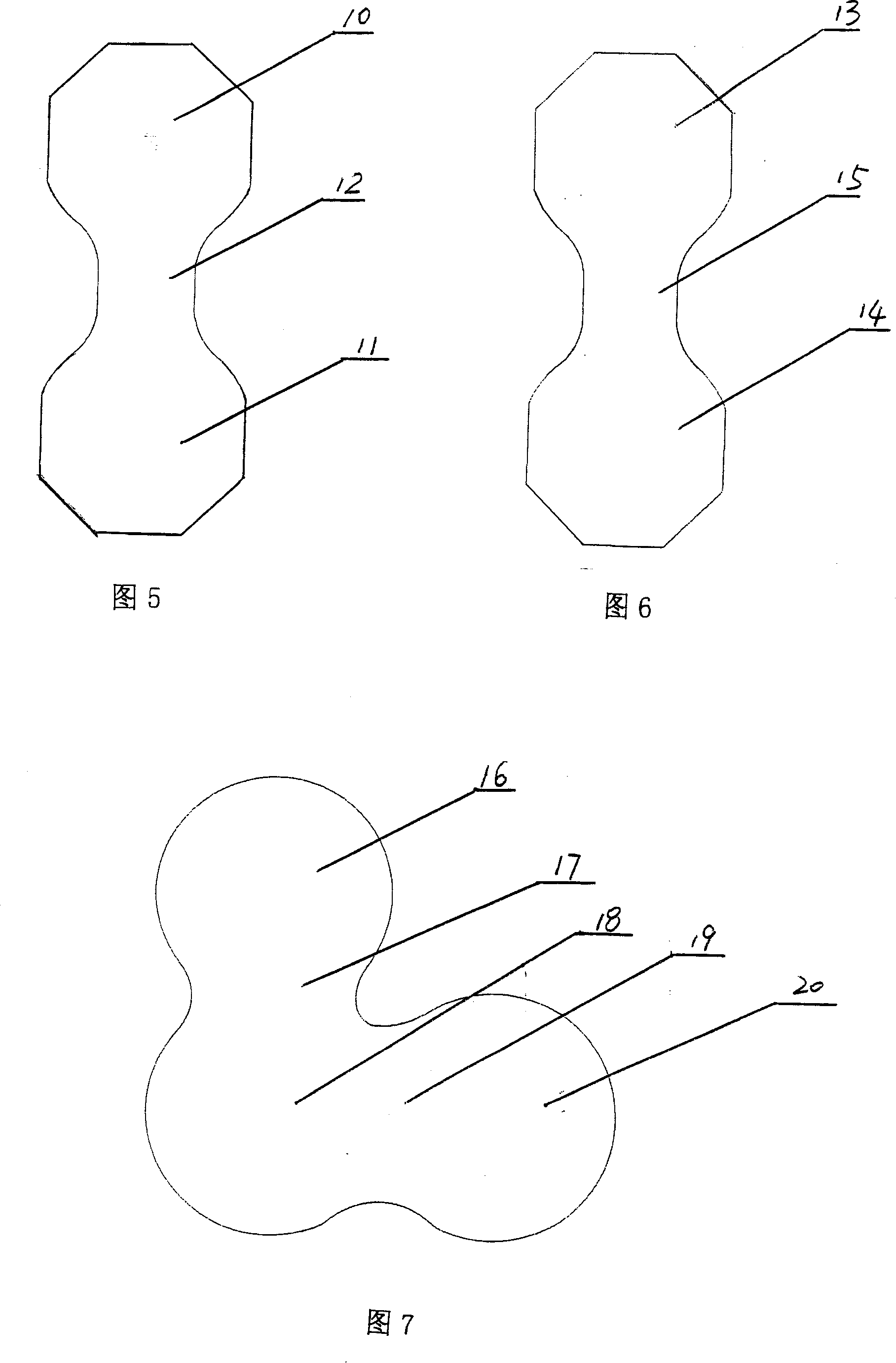

[0020] As shown in Figures 1 and 4: the present invention includes a positive plate 6 of a nickel electrode, a negative plate 4 made of multi-element multiphase electrochemical hydrogen storage alloy powder, a separator 5 arranged between the positive plate 6 and the negative plate 4 and through The sealing ring 3 and the battery cover 1 place the battery case 2 of the assembly of the above components, and a mesh gasket 9 is added between the inner bottom of the battery case inside the battery case 2 and the positive plate 6 , and between the negative plate 4 and the battery cover 1 Add mesh gasket 9 and spring gasket 7 between. Contact 8 is provided on the battery cover 1 .

[0021] As shown in Figures 1, 2, and 3: an assembly structure of the present invention is: the positive plate 6 and the negative plate 4 are all single-piece circular structures, and a mesh gasket 9 and a spring gasket 7 are added in the battery cover 1 , the single-piece negative plate is located on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com