Integrated pumping unit

A technology of oil pumping and power transmission devices, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of low utilization rate of single-machine single-well equipment, inability to balance each other, poor movement performance, etc., and achieve Effect of reducing weight and volume, less one-time investment, and improving system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

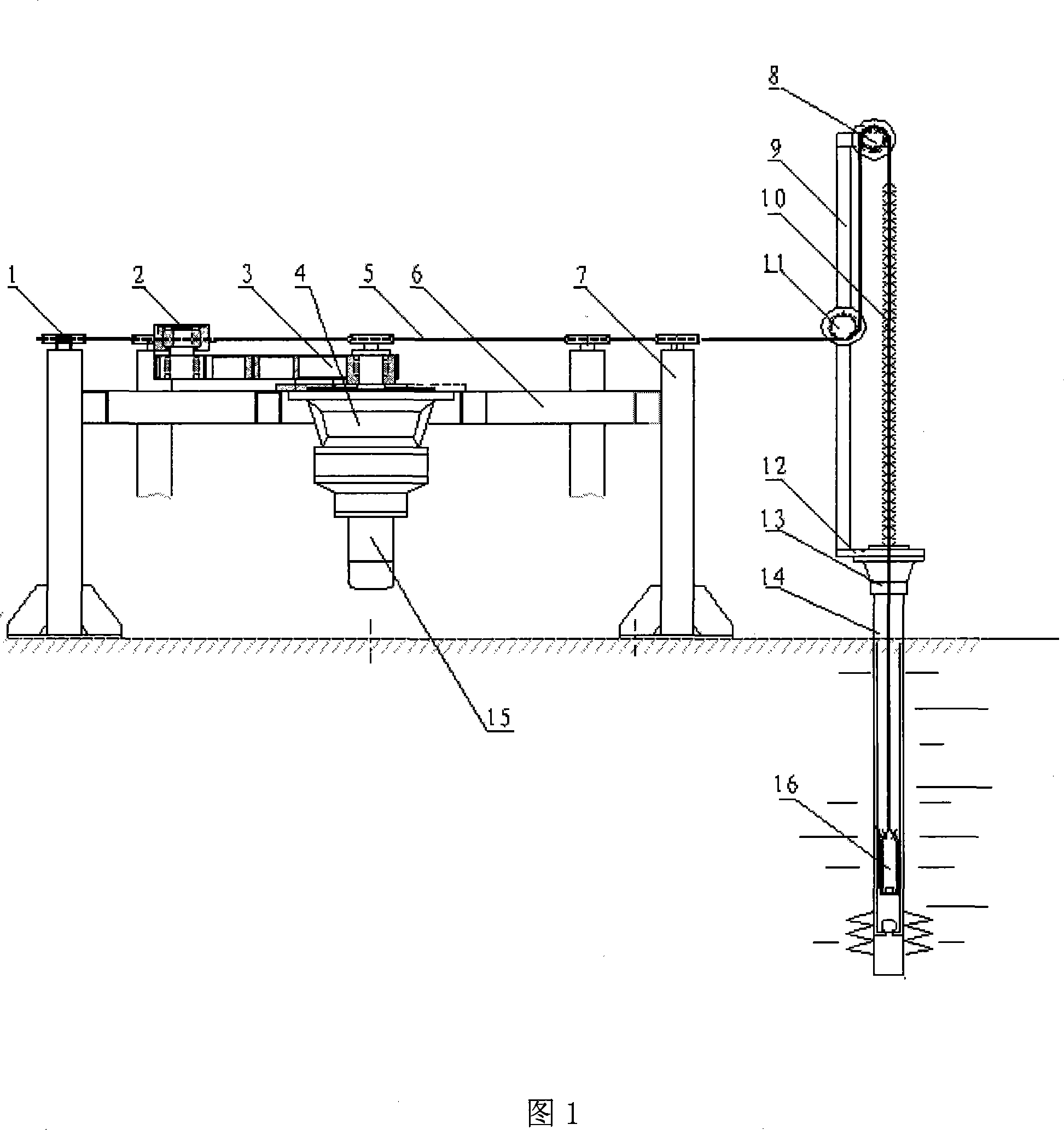

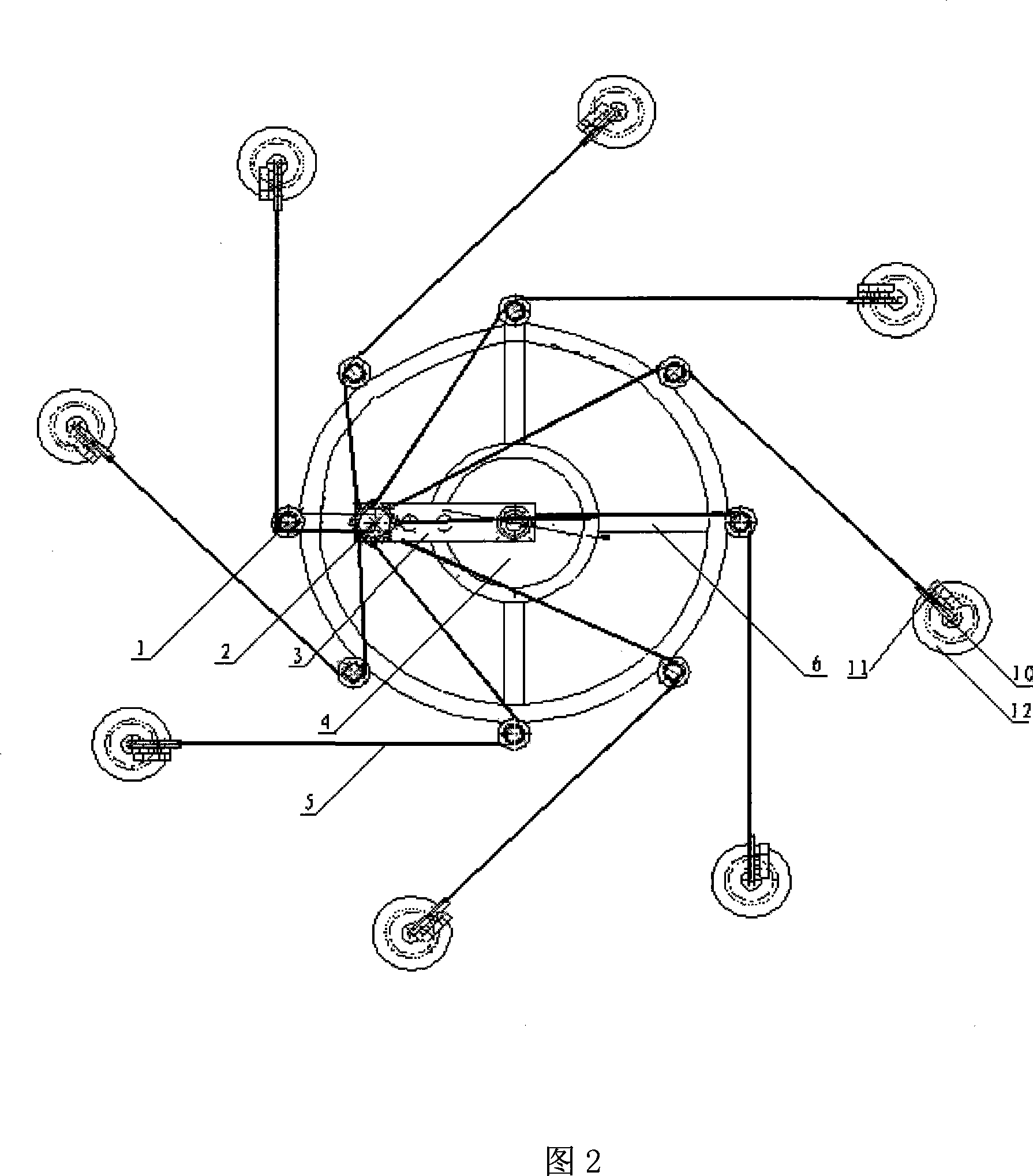

[0015] From Fig. 1 and Fig. 2, the oil pumping device of this integrated oil pumping device is made up of motor 15, speed reducer 4, frame 6, supporting leg 7, pulley block. A support 9 is vertically fixed on one side of the wellhead pressure plate 12, and an upper pulley 8 and a reversing pulley 11 are connected to the support 9; a plurality of legs 7 are vertically fixed on the frame 6 of the pumping unit, and the pumping unit does not need a foundation, which greatly saves oil. The basic construction cost of the machine; in the plane of the upper end of the frame, with the output shaft of the reducer as the center of the circle, there are a plurality of well-dividing pulleys 1 horizontally distributed sequentially, and the well-dividing pulleys 1 are fixed on the legs 7. The lower end of the frame is fixed with a motor 15 and a reducer 4 in turn, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com