Synchronous operation spacer of extensible guide device

A guide rail device and synchronous operation technology, applied in the direction of linear motion bearings, bearings, bearing components, etc., can solve the problems affecting smoothness, poor wear resistance, poor oil resistance, etc., and achieve smoother, more stable and better results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

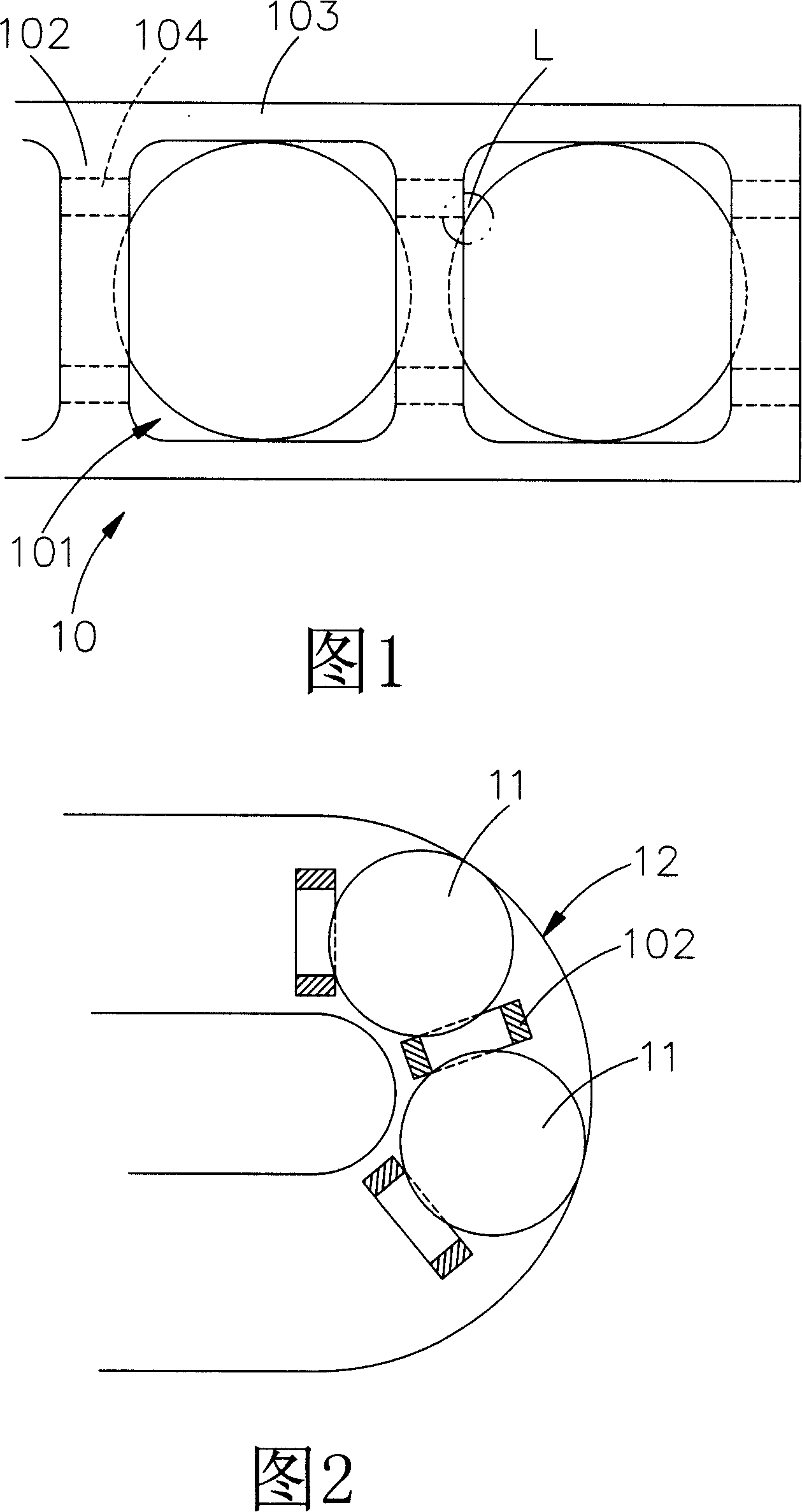

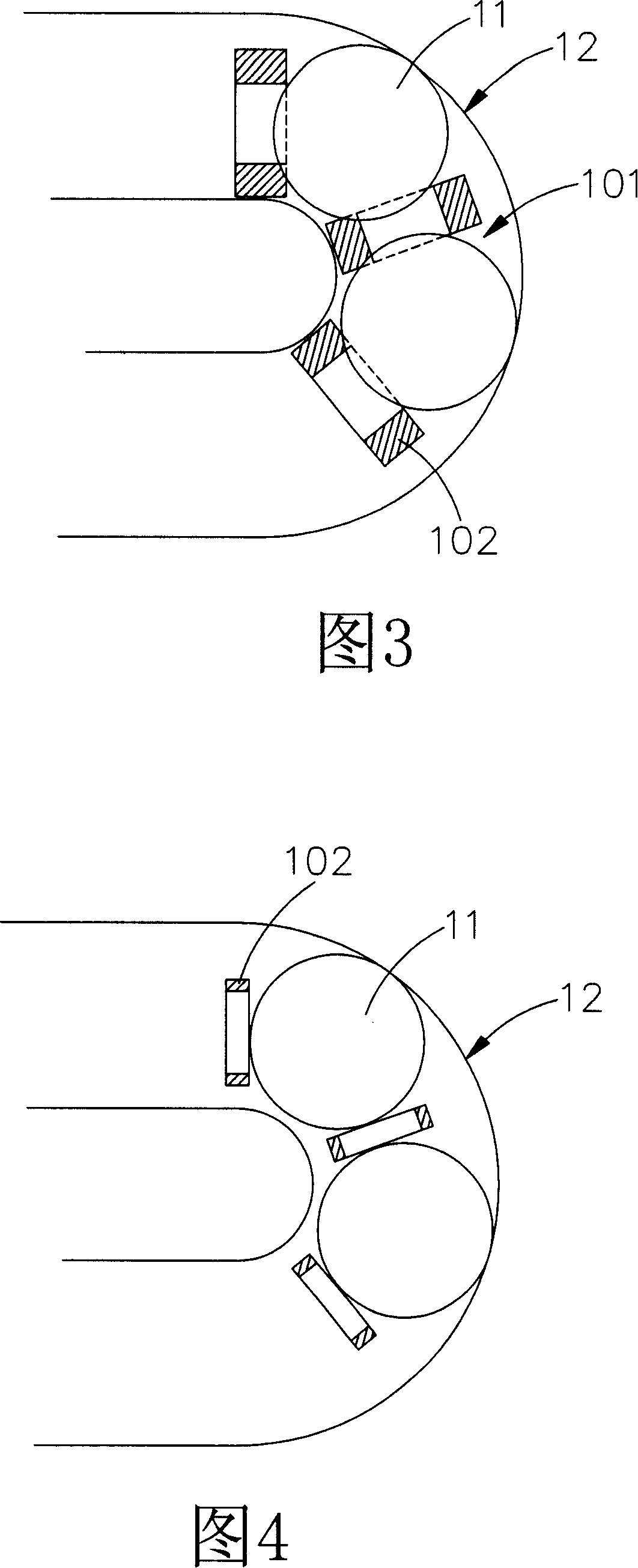

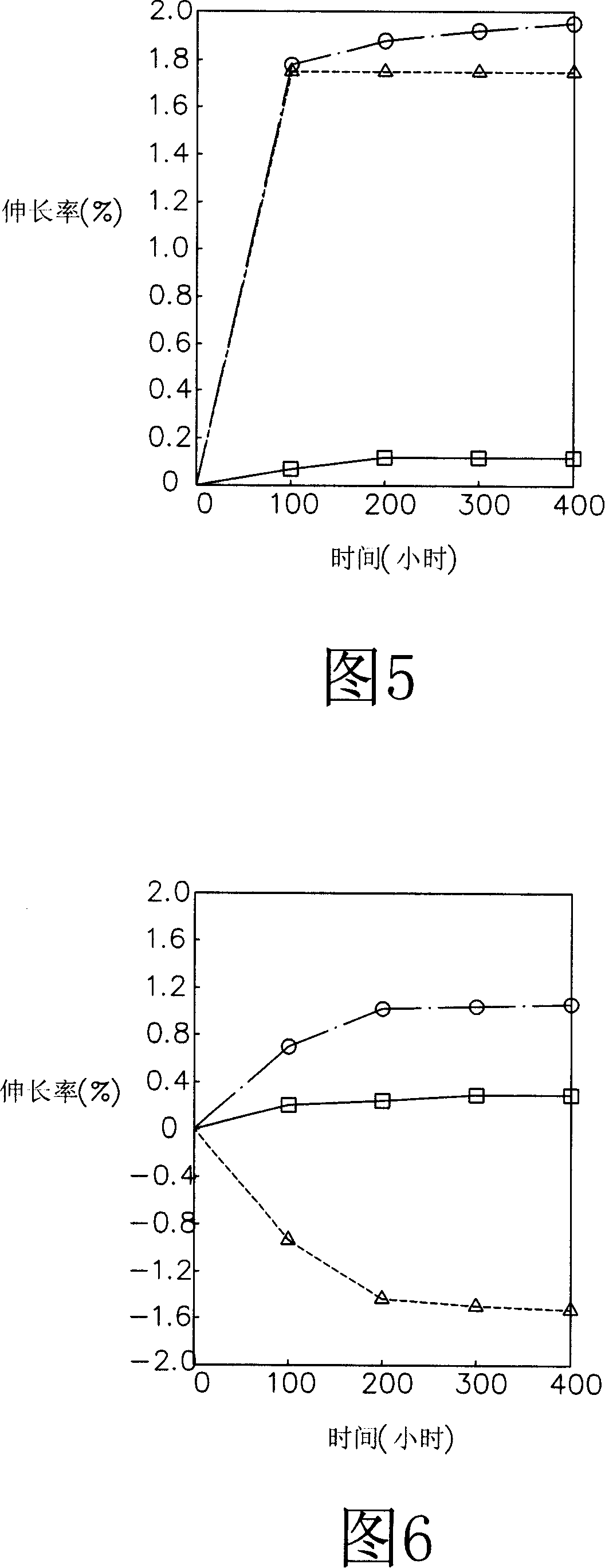

[0036] Please refer to Fig. 9, the spacer 10 of the present invention comprises a plurality of spacers 102 and a strip-shaped connecting portion 103, the connecting portion 103 integrally connects a plurality of spacers 102, each spacer 102 is provided with an accommodation space 101, and the interval The spacers 102 are spaced between the rolling assemblies 11 of the guide rail device. Each spacer 102 is provided with an abutting portion 104 between the rolling assemblies 11 on both sides corresponding to the path direction of the rolling assemblies 11. The abutting portion 104 is located at the periphery of the accommodation space 101. And the abutting portion 104 corresponds to the rolling assembly 11 to make an error gap L greater than 0.3% of the size of the abutting portion. % thermoplastic polyurethane elastomer; the aforementioned structure and technology are the key structure and technical details of the present invention.

[0037] Please refer to the following descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com