Smoke canal water sealing float bowl switching mechanism absorbing refrigeration system with tail gas or gas

A technology of adsorption refrigeration and tail gas, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of high processing cost and long cycle, and achieve the effect of low cost, high degree of automation and reliable principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

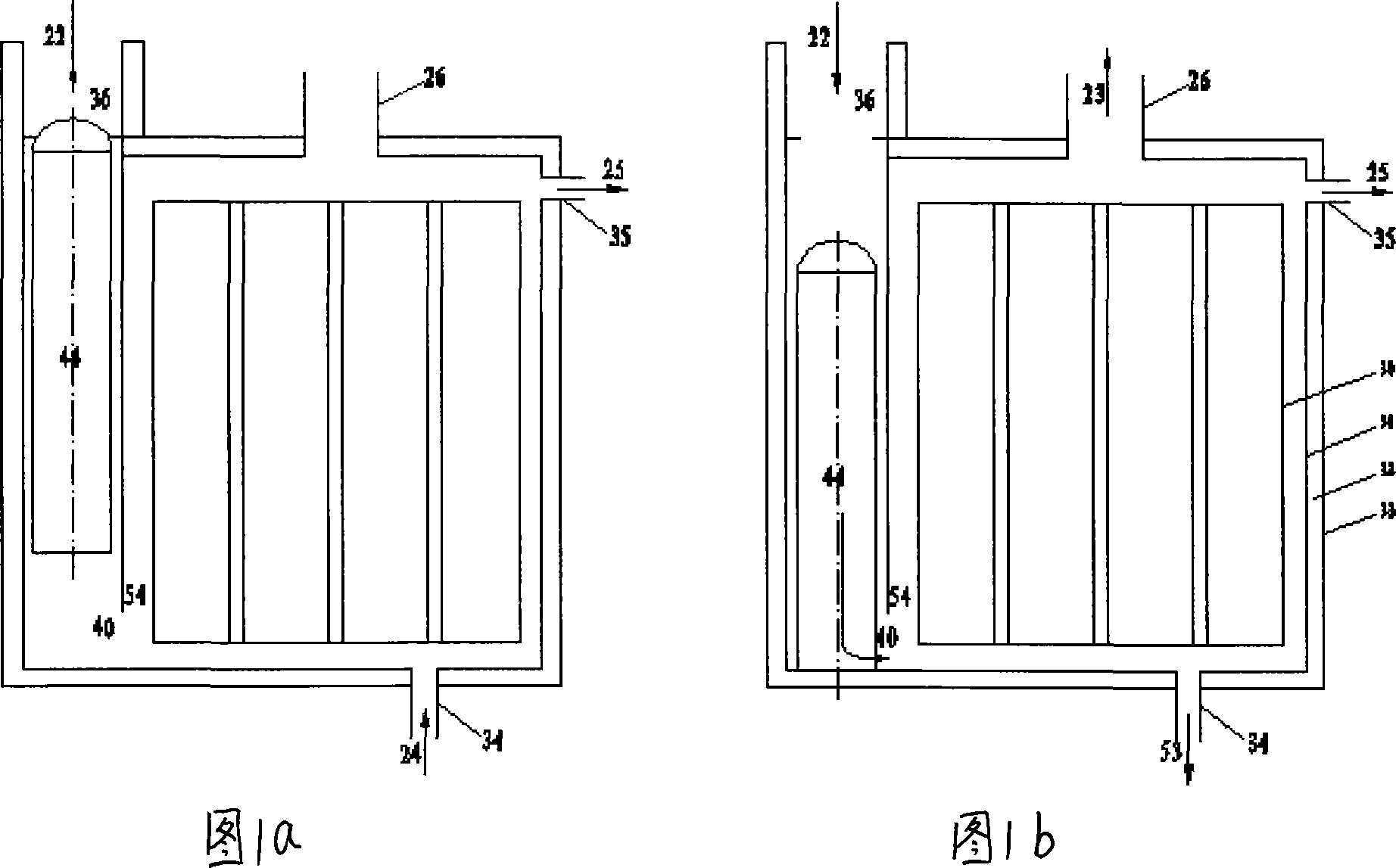

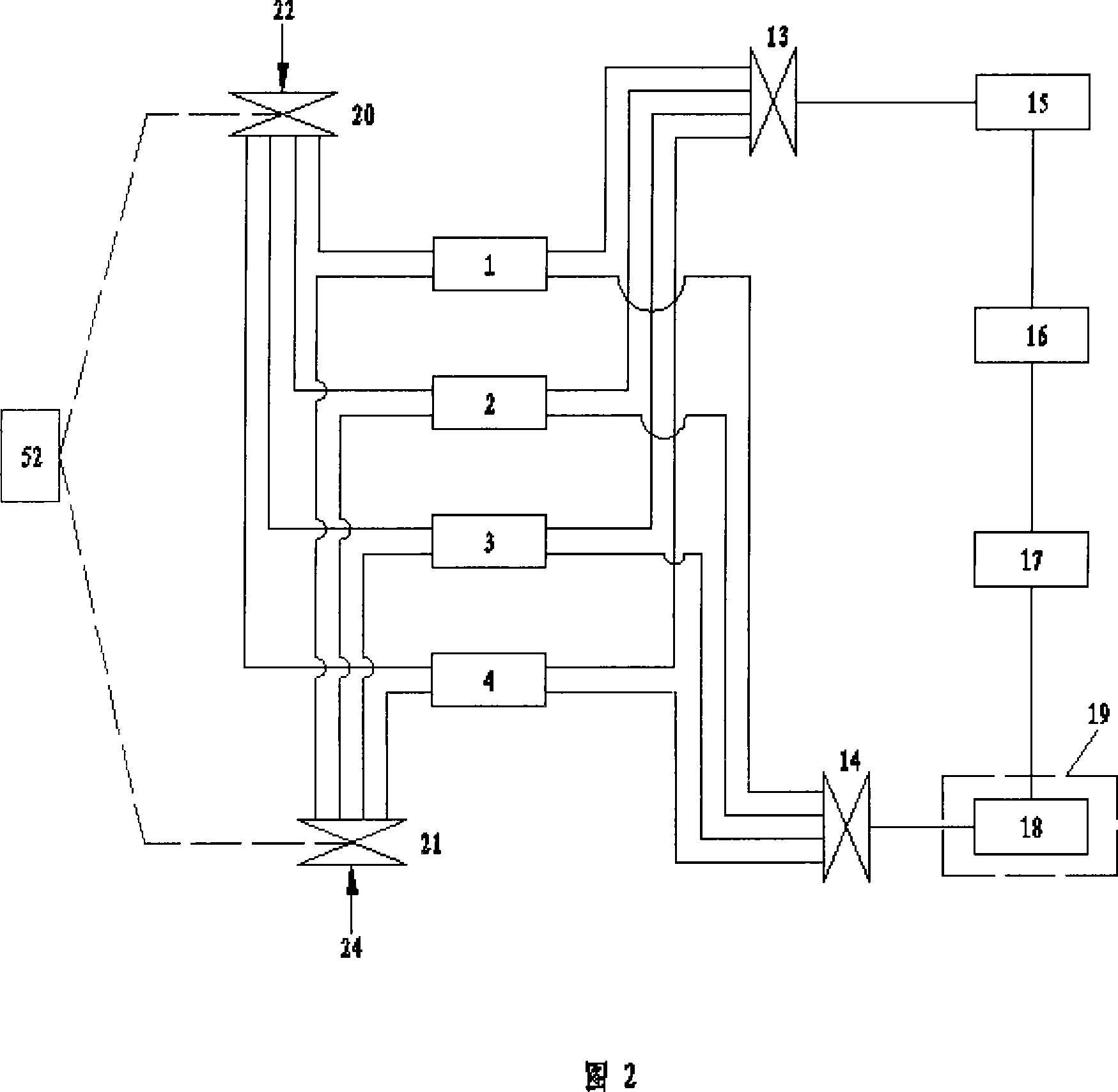

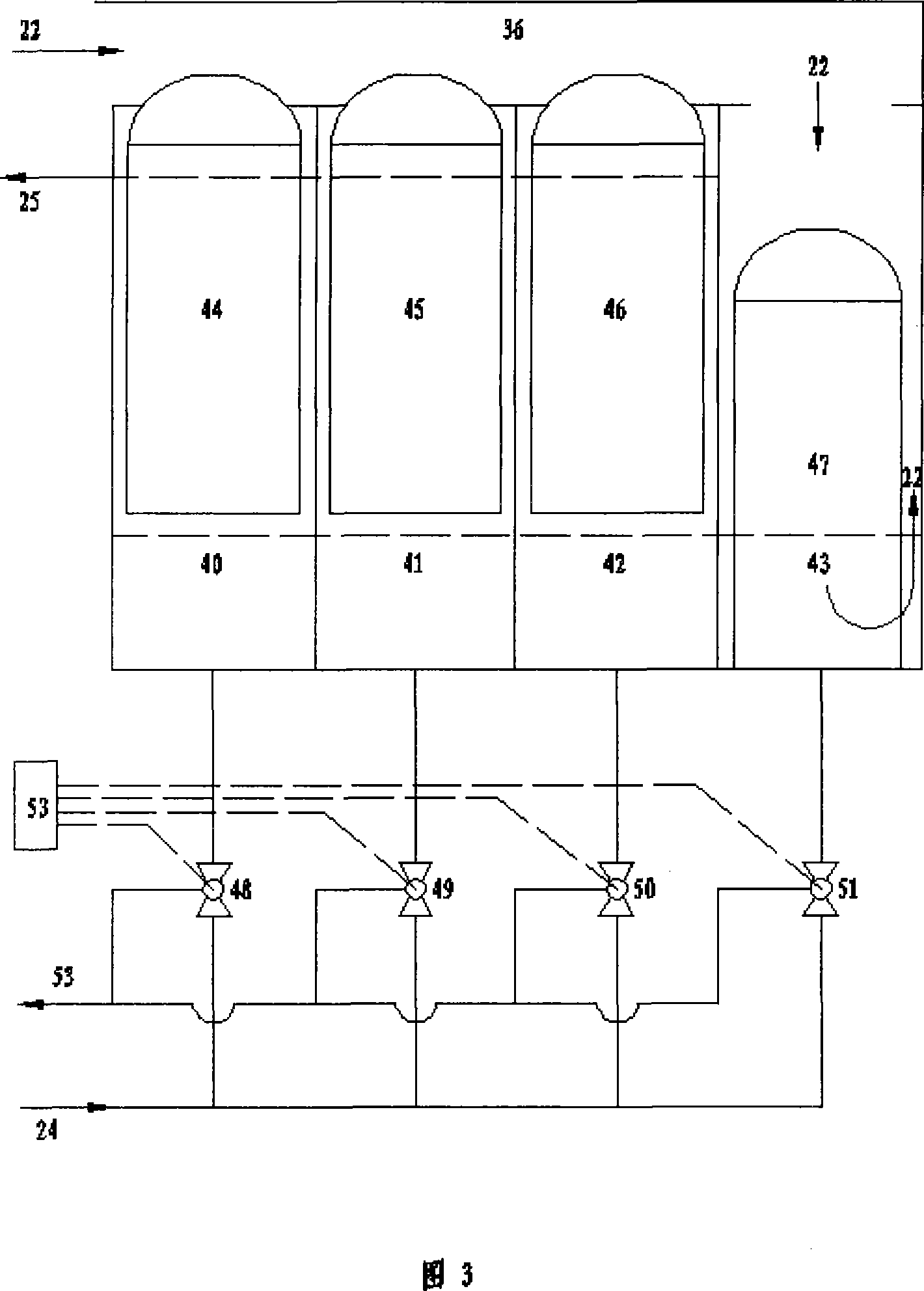

[0026] The present invention will be further described below in conjunction with accompanying drawing.

[0027]It can be seen from Fig. 3 that the present invention includes water seals and water seal buoys (44, 45, 46, 47), electric water valves (48, 49, 50, 51) and PLC programmable controller 52, which together constitute an adsorption refrigeration system The cooling water input and exhaust gas or gas input automatically control the switching mechanism. Here, the exhaust gas or gas adsorption refrigeration system of 4 generators is taken as an example, and the switching between the adsorption state and the desorption state of the generator is explained. Figure 1 shows the function of water seal and water seal buoy to close and open the flue in a single generator. In the figure, the generator inner casing 31 and the tail gas or gas input sub-pipe 40 are designed as one with the flue, and the water and water-sealed buoy 39 will close the tail gas or gas input sub-pipe 40. Or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com