Program automatically triggering system and device

A technology of automatic triggering and programming, applied in the direction of program control device, program control, general control system, etc., can solve the problems of wrong action of output equipment, omission of instructions, cost reduction, etc., to save placement, reduce errors and errors, The effect of increasing acceptance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

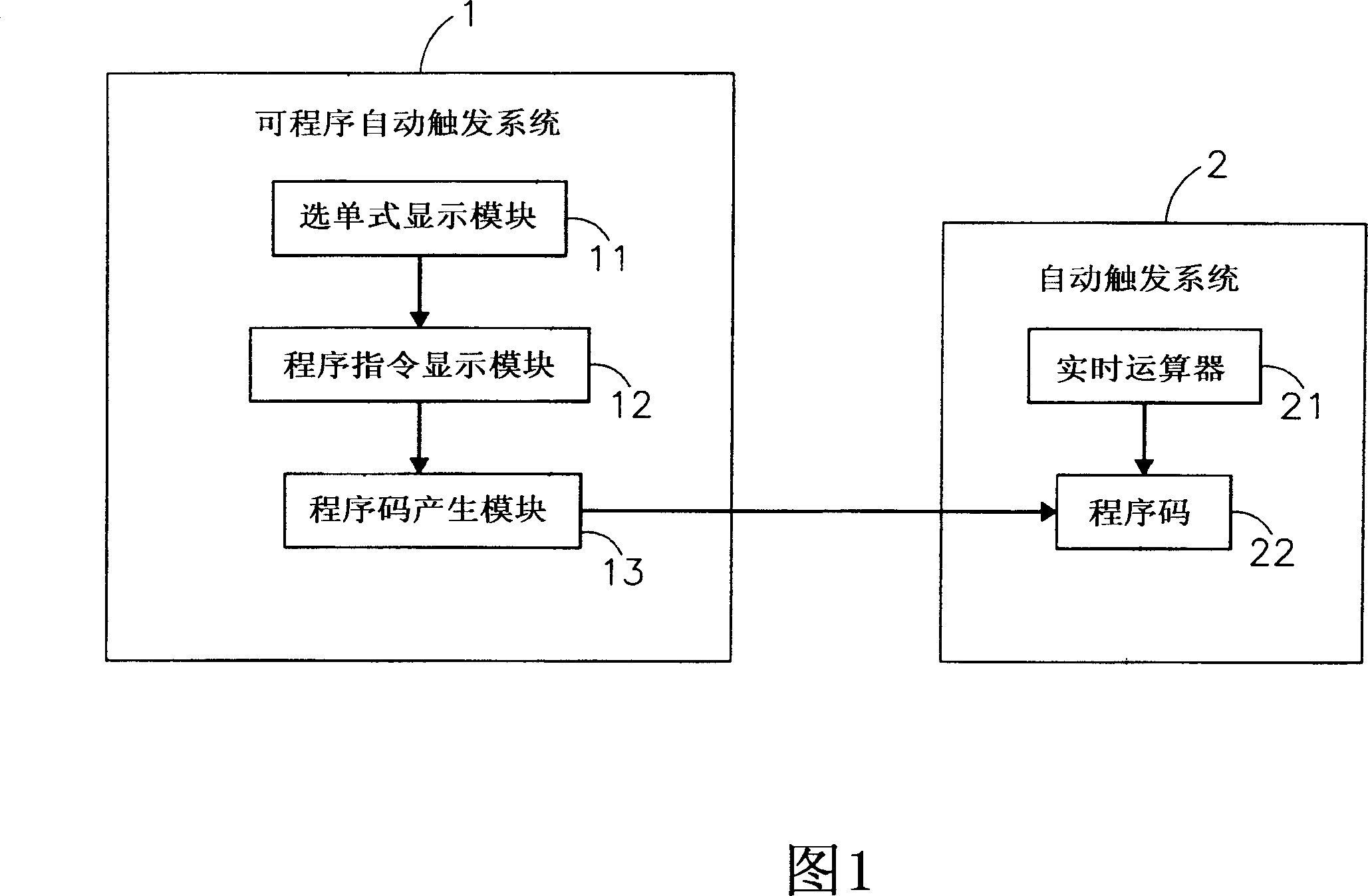

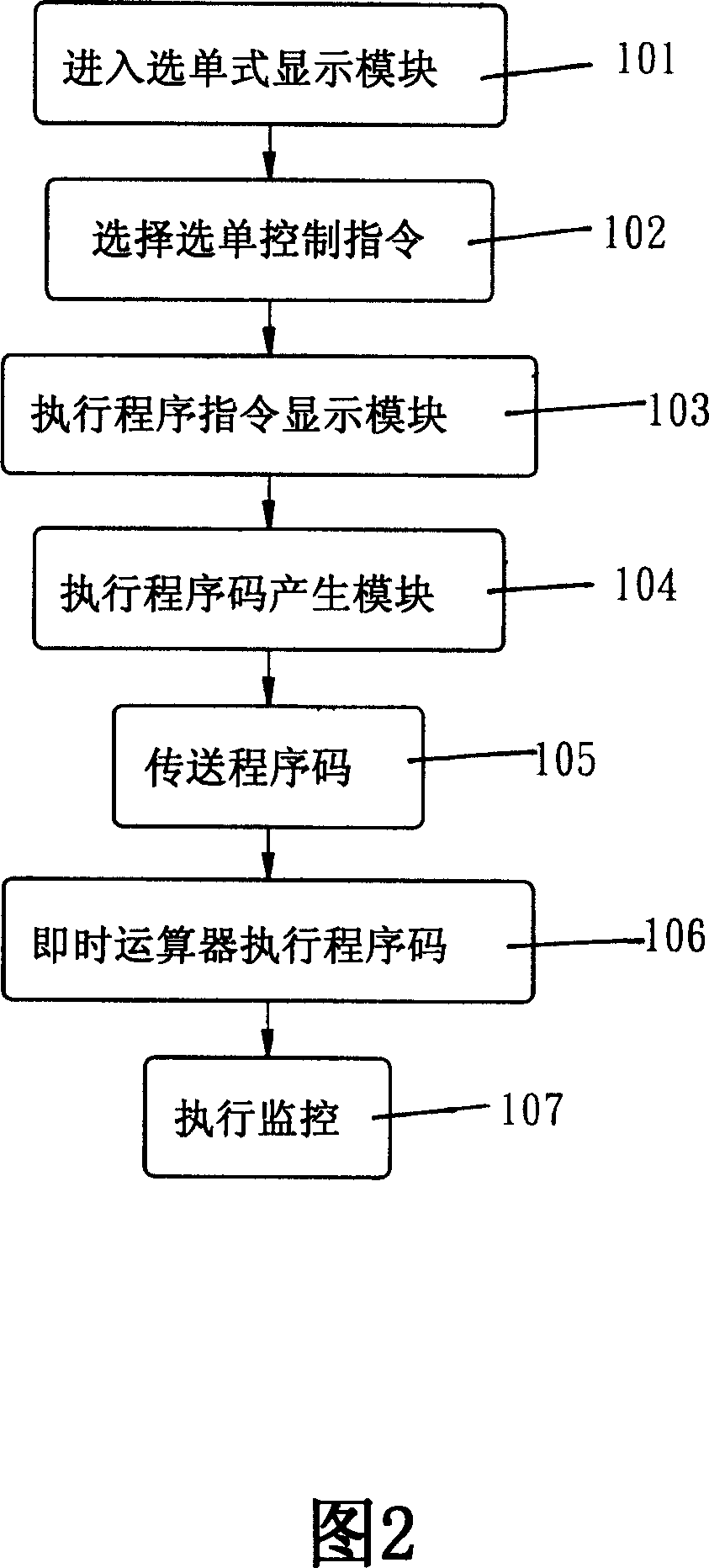

[0039] See also shown in Fig. 1, be the block diagram of preferred embodiment of the present invention, can clearly find out by shown in the figure, the method of the present invention comprises programmable automatic triggering system and device, by programmable automatic triggering system 1 and automatic Trigger device 2 is formed, and wherein so with regard to the main structural feature of this case detailed description as follows, wherein:

[0040] This programmable automatic trigger system 1 includes a menu display module 11, a program instruction display module 12 and a program code generation module 13. The menu display module 11 includes one or more input terminal menu control instructions, and each menu The control commands also have corresponding output menu control commands for users to select the corresponding menu control commands in sequence; and the program command display module 12 is for displaying the menu control commands selected by the menu display module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com