Liquid processing system

A liquid treatment and treatment liquid technology, which is applied in the fields of semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve the problems of enlarged piping space, complicated piping arrangement, and difficulty in uniform treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, embodiments of the present invention will be described with reference to the drawings. However, in the following description, the same reference numerals are assigned to components having substantially the same functions and configurations, and descriptions are repeated only when necessary. Here, a case where the present invention is applied to a liquid processing system for cleaning the front and back of a semiconductor wafer (hereinafter simply referred to as wafer) will be described as an example.

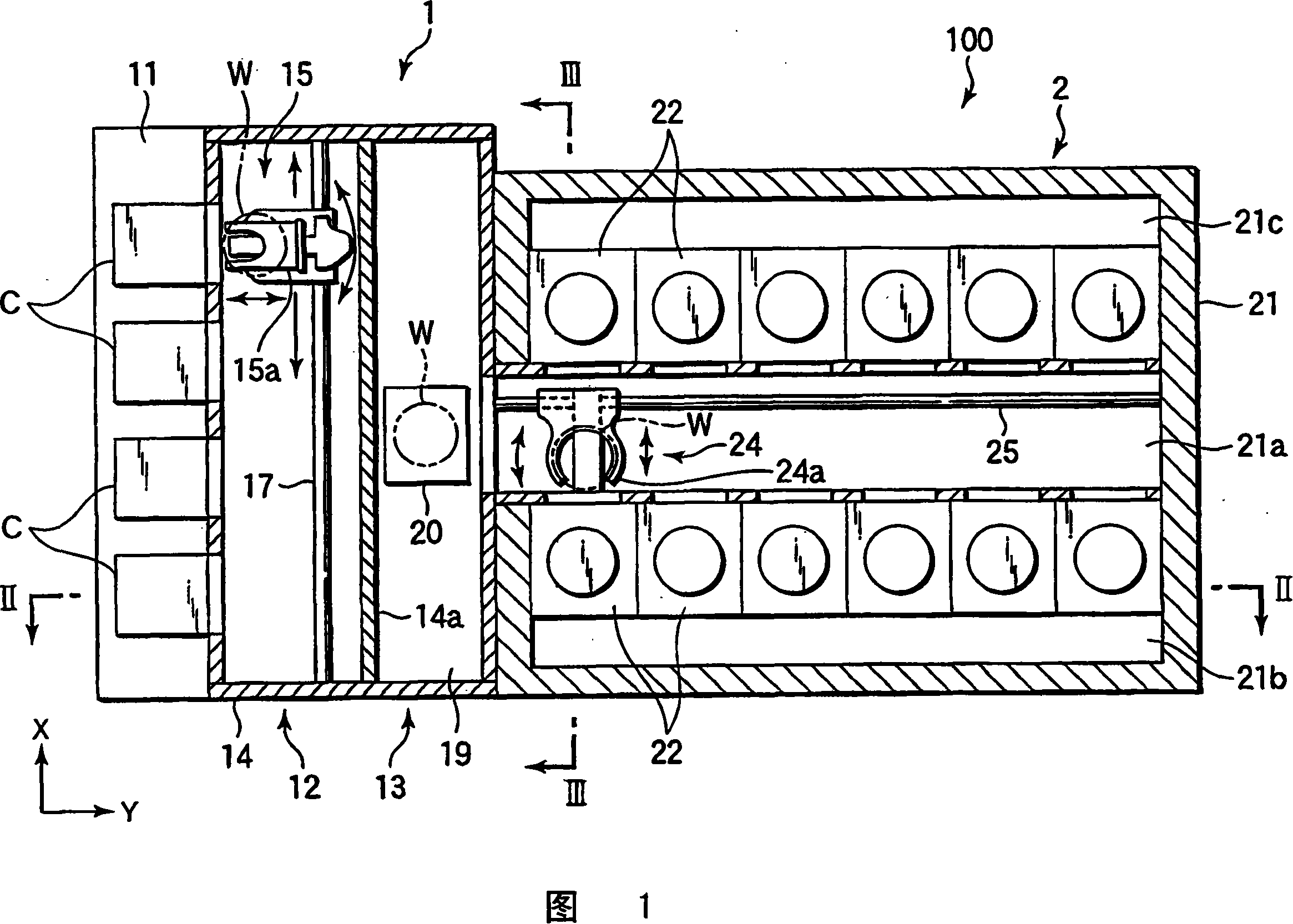

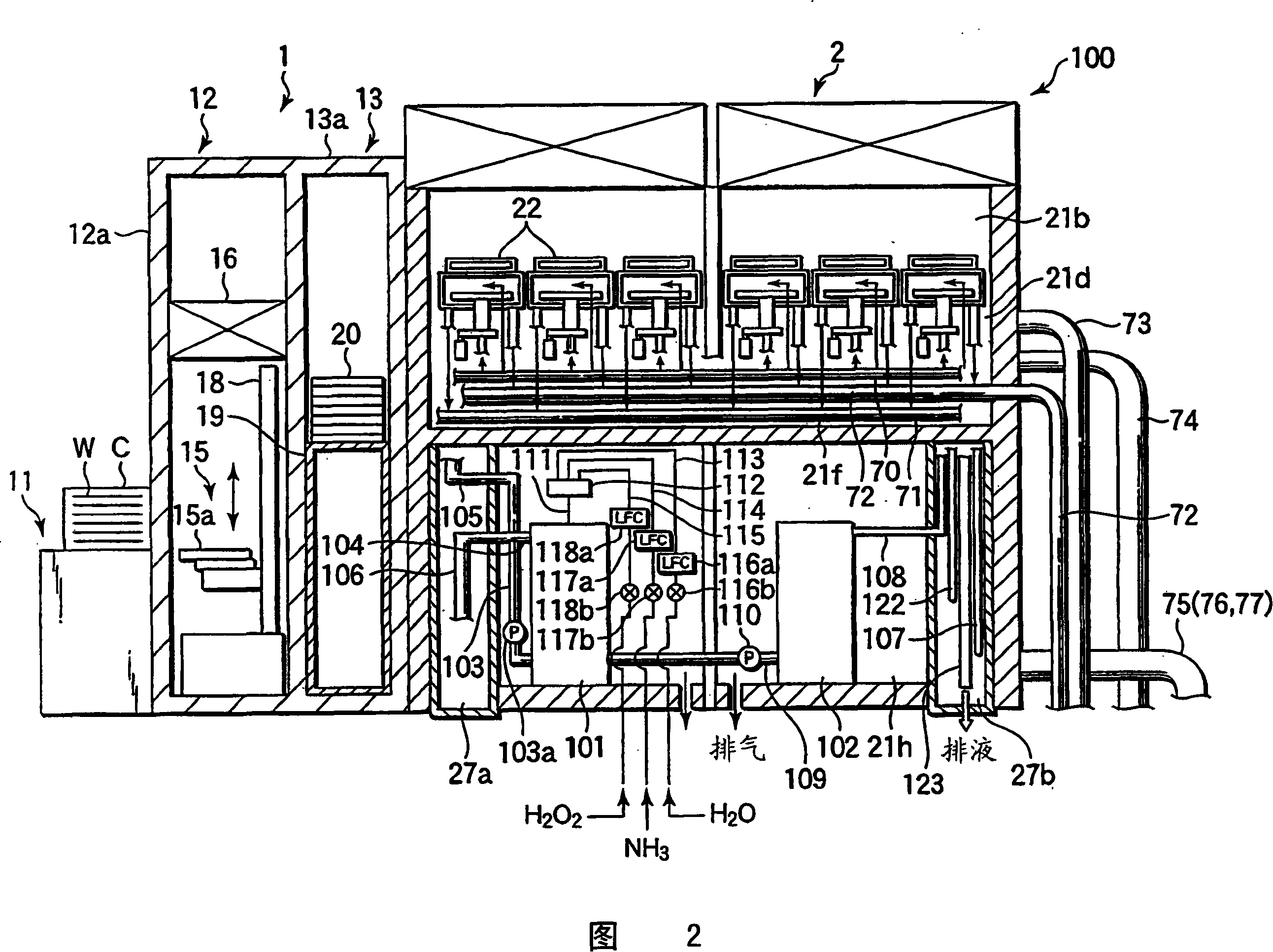

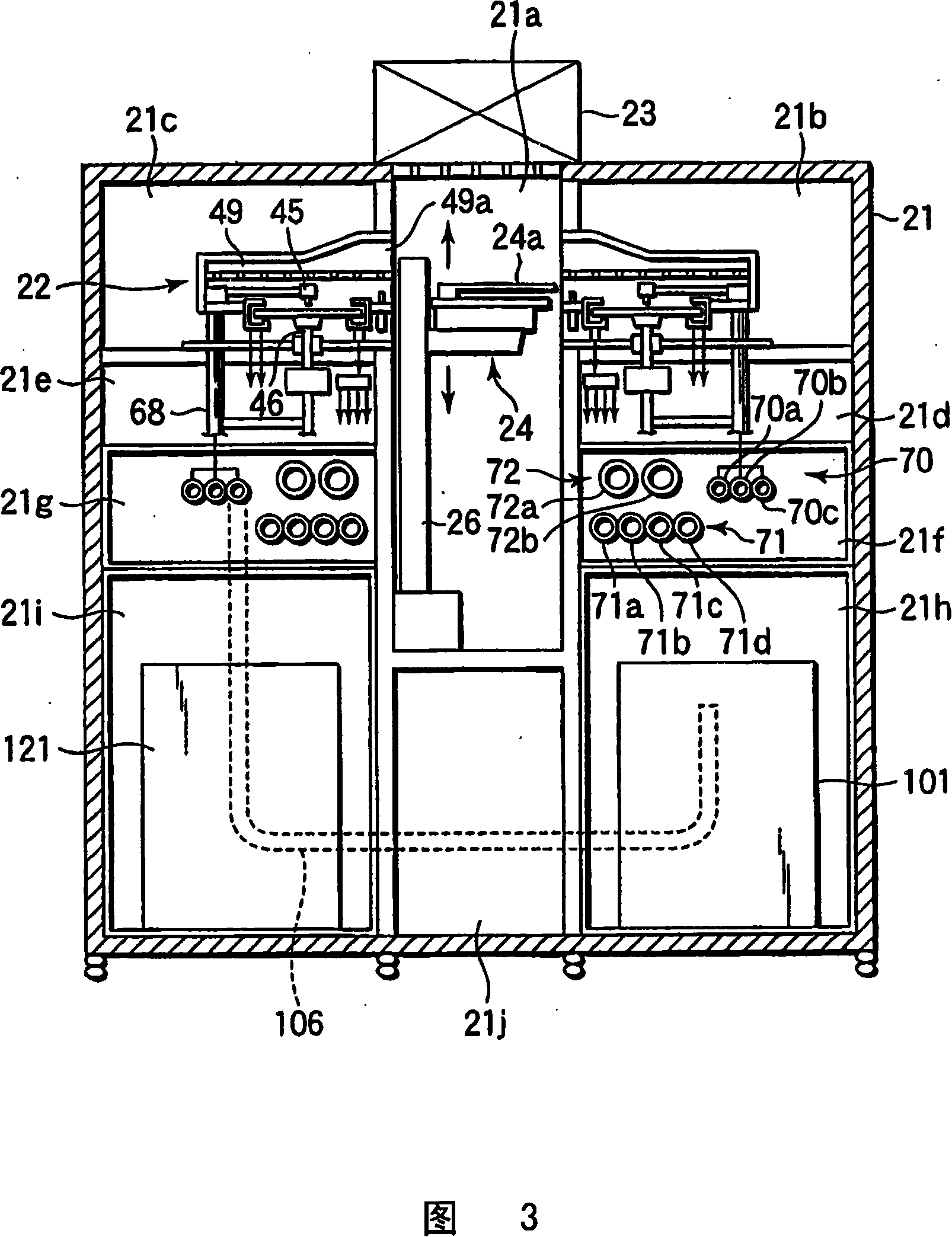

[0019] FIG. 1 is a plan view showing a schematic configuration of a liquid processing system according to an embodiment of the present invention. FIG. 2 is a cross-sectional view of the front side along line II-II of FIG. 1 . Fig. 3 is a side cross-sectional view along line III-III of Fig. 1 .

[0020] The liquid processing system 100 includes an input / output station (substrate input / output unit) 1 and a processing station (liquid processing unit) 2 that ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com