Method and device for the wet treatment of items to be washed

A washing and wet treatment technology, which is applied in the direction of washing devices, applications, household appliances, etc., can solve problems such as consumption, achieve the effects of saving fresh water, saving space, and improving washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

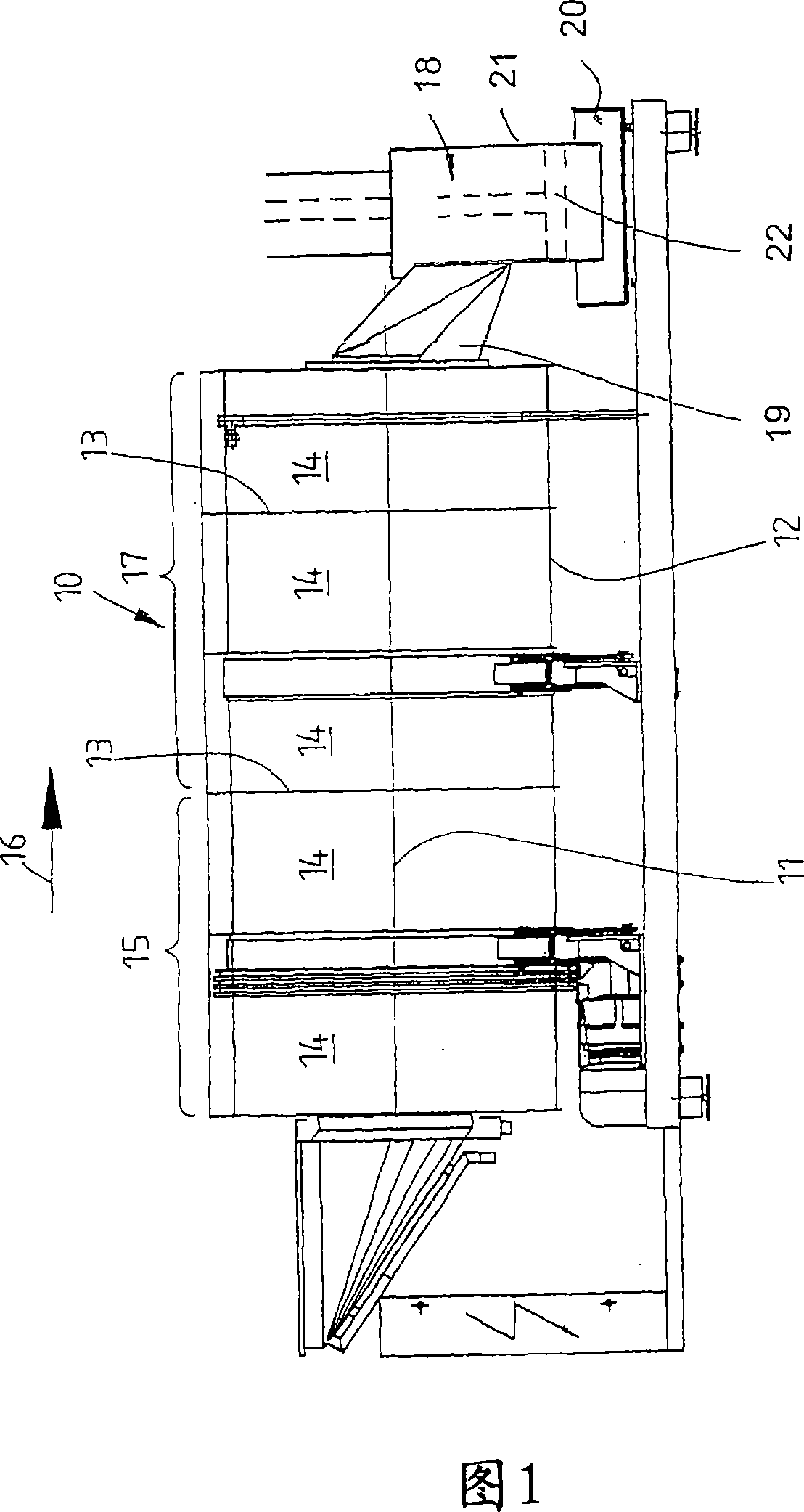

[0021] The apparatus shown here constitutes a washing automatic line for the wet processing of laundry, in particular for washing, rinsing and dewatering of said laundry. The plant has a simplified tunnel washer 10 , which, contrary to conventional tunnel washers, is also suitable for washing small loads starting from 150 kg / h.

[0022] The tunnel washing machine 10 has a drum 12 that is rotatably driven about a preferably horizontal axis of rotation 11 . A plurality of successive chambers 14 are formed in the drum 12 by transversely oriented partition walls 13 in the passage direction 16 of the laundry, not shown, through the drum 12 . Since the tunnel-type washing machine 10 of the present invention does not need to have an outer drum arranged at least part of the drum 12, the tunnel-type washing machine 10 without an outer drum is used in the present invention.

[0023]There are essentially only two treatment zones in the drum 12 of the tunnel washing machine 10, and these...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com