Ammoxidation method to manufacturing unsaturated nitrile fluid-bed catalyst

A nitrile fluidized bed and ammoxidation technology, applied in the field of fluidized bed catalysts, can solve the problem of low reaction yield of acrylonitrile catalysts, and achieve the effects of inhibiting the formation of by-products, high catalyst activity, and good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

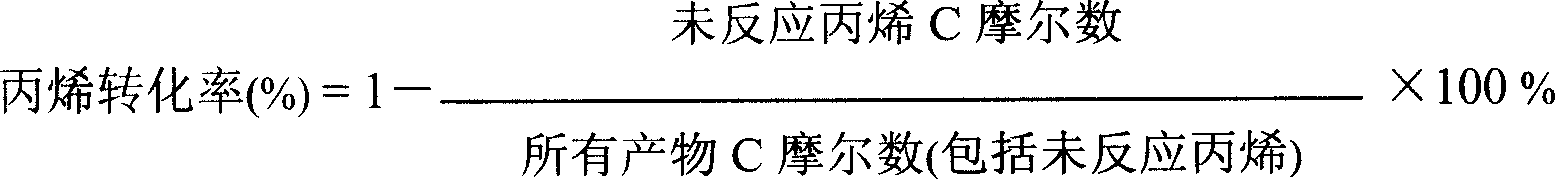

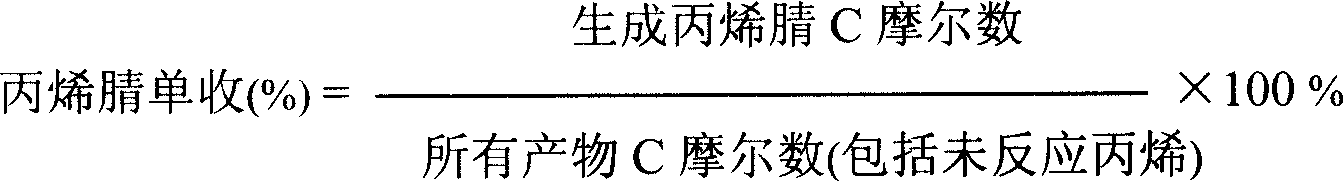

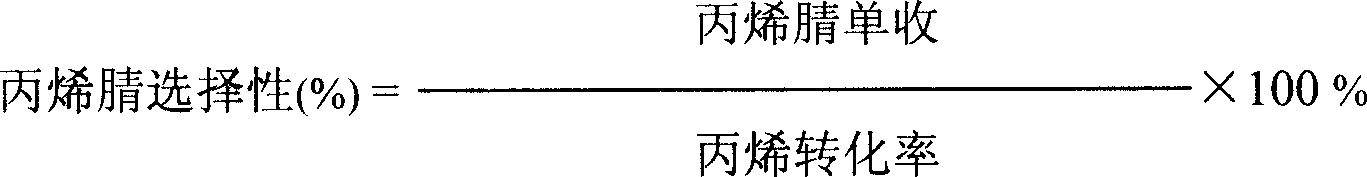

Method used

Image

Examples

Embodiment 1~11

[0045] According to the same preparation process as the comparative example, the catalyst composition was prepared according to Table 1. The finished catalysts were inspected according to the above-mentioned inspection and evaluation conditions, and the initial activity results are shown in Table 2. The 250-hour stability test results of Comparative Example 1 and Example 5 are shown in Table 3.

[0046] Table 1 Catalyst

[0047] Catalyst composition

comparative example

Mo 12 Bi 2.0 Fe 2.5 Ni 4.5 Mg 1.8 La 0.8 SM 0.2 K 0.05 Cs 0.05 Na 0.05 +50% SiO2 2

Example 1

Mo 12 Bi 1.2 Fe 2.5 Ni 4.5 co 2.0 Ce 0.8 SM 0.2 PR 0.5 K 0.03 Na 0.05 +50% SiO2 2 +10%Al 2 o 3

Example 2

Mo 12 Bi 0.5 Fe 1.8 Ni 6.0 Mg 2.5 La 0.8 Ge 0.2 K 0.1 Cs 0.05 Na 0.04 +30% SiO2 2 +20%Al 2 o 3

Example 3

Mo 12 Bi 0.2 Fe 2.0 Ni 6.8 Mg 0.8 SM 0.6 Cs 0.05 Ge 0.5 +52% SiO2 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com