Large-area pectinate spraying head used for metal organic chemical gas phase deposition device

A chemical vapor deposition, metal-organic technology, applied in gaseous chemical plating, metal material coating process, spray device and other directions, can solve the problem that the composition and thickness uniformity of the deposition material cannot meet the requirements, waste source gas, Problems such as the inability to measure gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

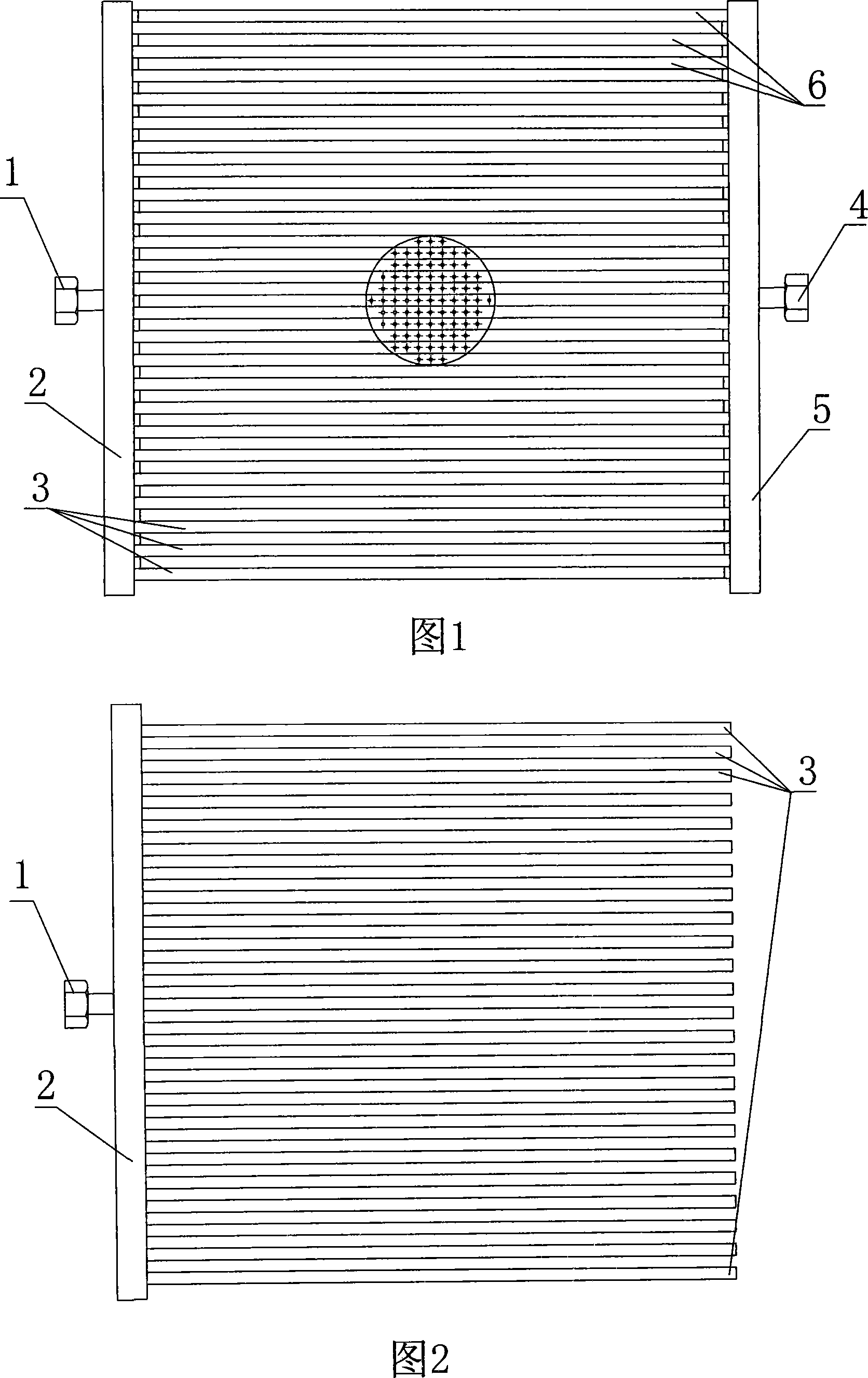

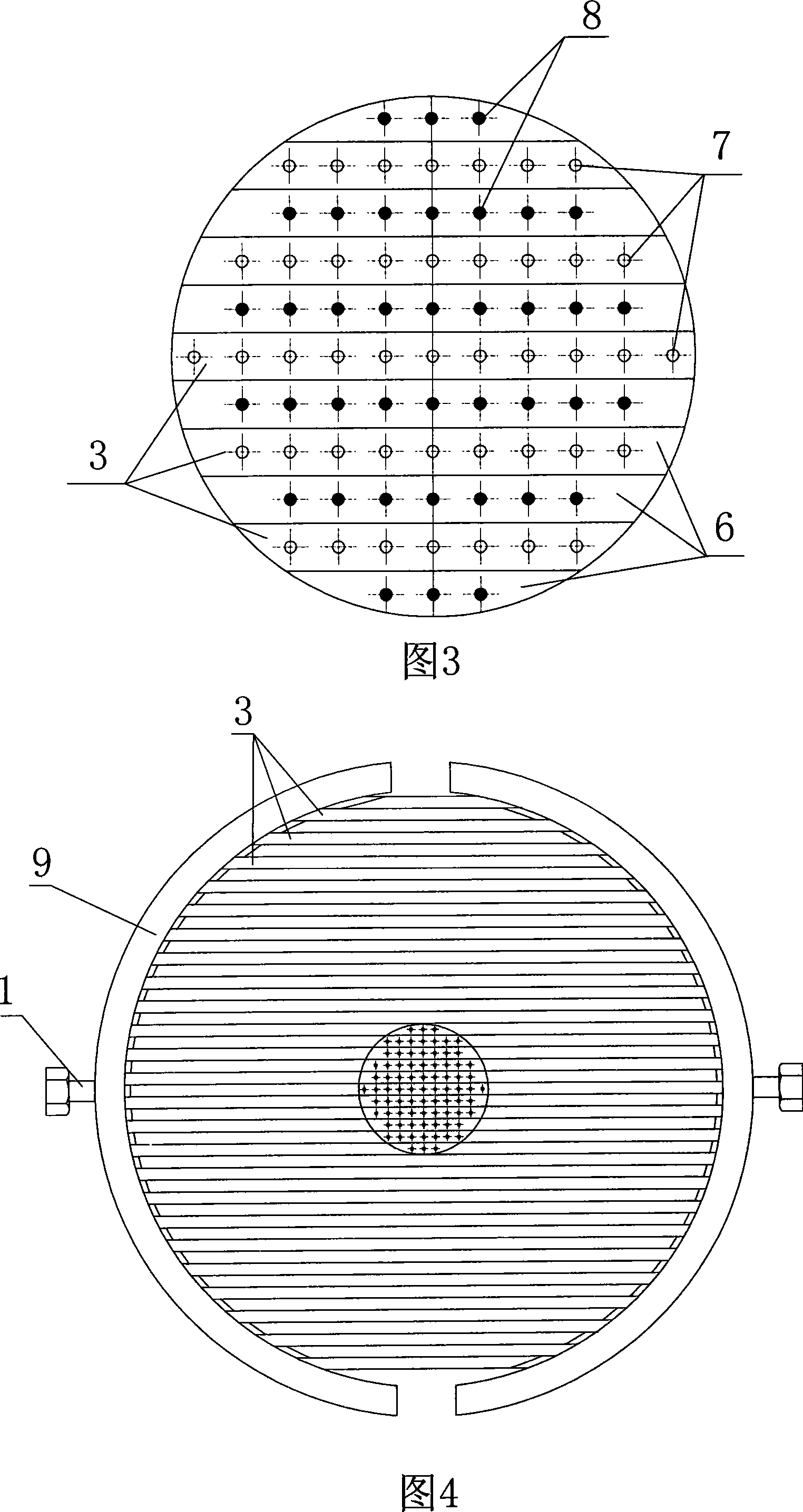

[0019] According to Fig. 1 to Fig. 3 and the large-area comb-shaped shower head of above-mentioned structure, be used for the air supply device in the reaction chamber of metal organic compound chemical vapor deposition (MOCVD) equipment, it has two groups of comb-shaped shower heads, wherein the first The group of comb-shaped shower heads is composed of a gas A main pipe 2 equipped with an air inlet joint 1 and a plurality of gas A ventilation branch pipes 3 arranged in parallel, one end of each gas A ventilation branch pipe 3 communicates with the gas A main pipe 2 and The other end is a closed end, and the second group of comb-shaped shower heads is composed of a gas B main pipe 5 equipped with an air inlet joint 4 and a plurality of gas B ventilation branch pipes 6 arranged in parallel, and one end of each gas B ventilation branch pipe 6 is the same as The gas B main pipe 5 is connected and the other end is a closed end. Its structural feature is that the gas A ventilation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com