Asynchronous type suspension conveyor

A suspension conveyor, asynchronous technology, applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of large floor area, limited functions, high cost, etc., to achieve less floor area occupied and flexible arrangement , the effect of convenient lateral movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

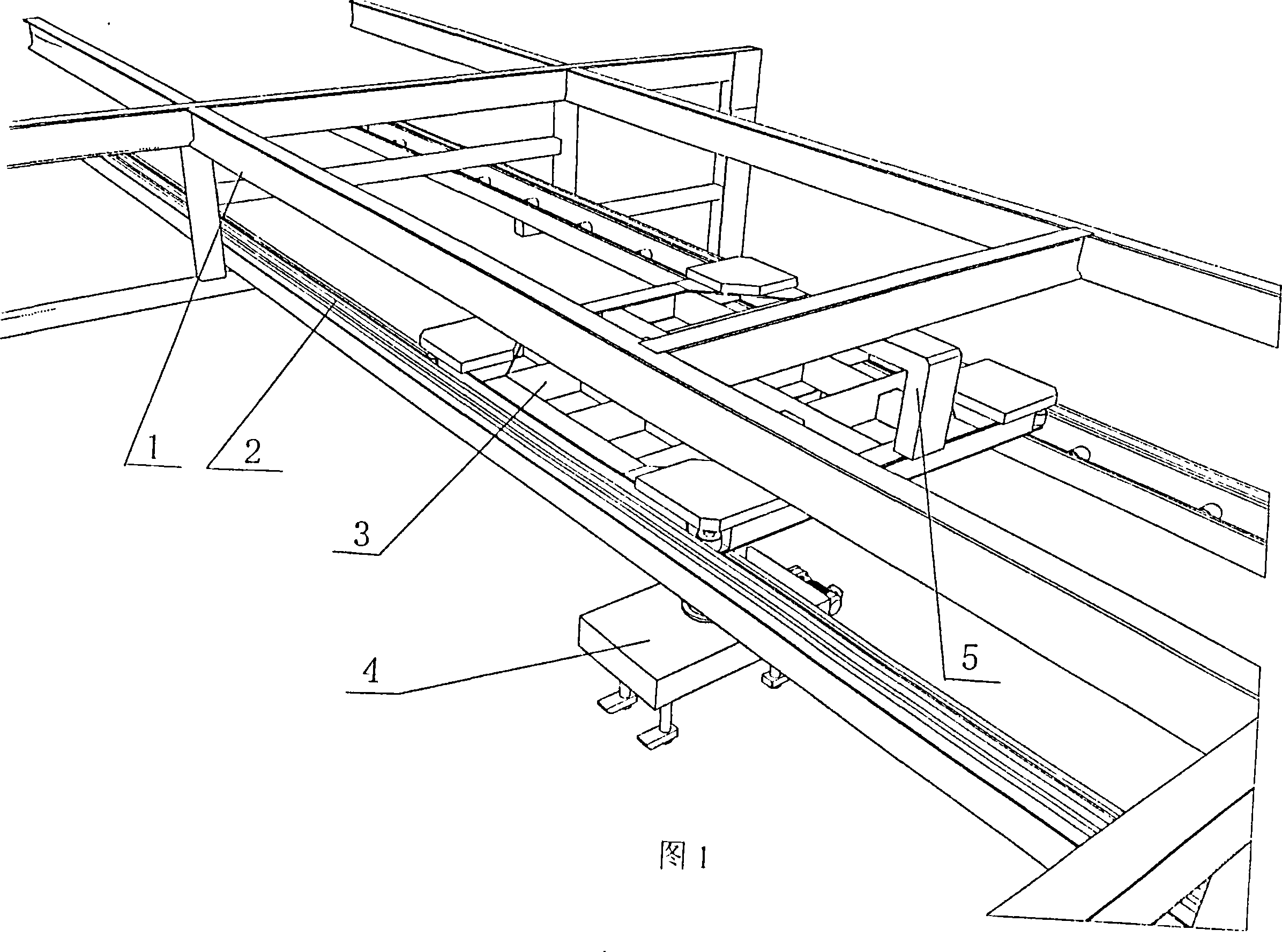

[0008] Referring to the accompanying drawings, its structure includes a steel structure frame 1, an asynchronous conveying device 2, a walking tray 3, a secondary tooling 4, and a stopper 5, wherein the asynchronous conveying device 2 is supported and installed by the steel structure frame 1 installed in the air in such a way that the asynchronous conveying device 2 is in two parallel rows, and the conveying surfaces of the rollers or chains on the asynchronous conveying device 2 are on the same horizontal plane, the walking pallet 3 is placed on the conveying device, and the walking pallet 3 Secondary tooling 4 is installed on the lower surface of the frame, and the stopper 5 is installed on the steel frame 1.

[0009] Utilize the steel structure frame 1, install the traditional asynchronous conveying device 2 in the air, or install it at a height that allows the pallet suspension bogie or wheel set to pass through, the walking pallet 3 is placed on the conveying device, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com