Automobile body coating lifting assembly

A technology of automobile body and spreader, which is applied in the direction of transportation and packaging, load hanging components, etc., and can solve the problems of extended working hours and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

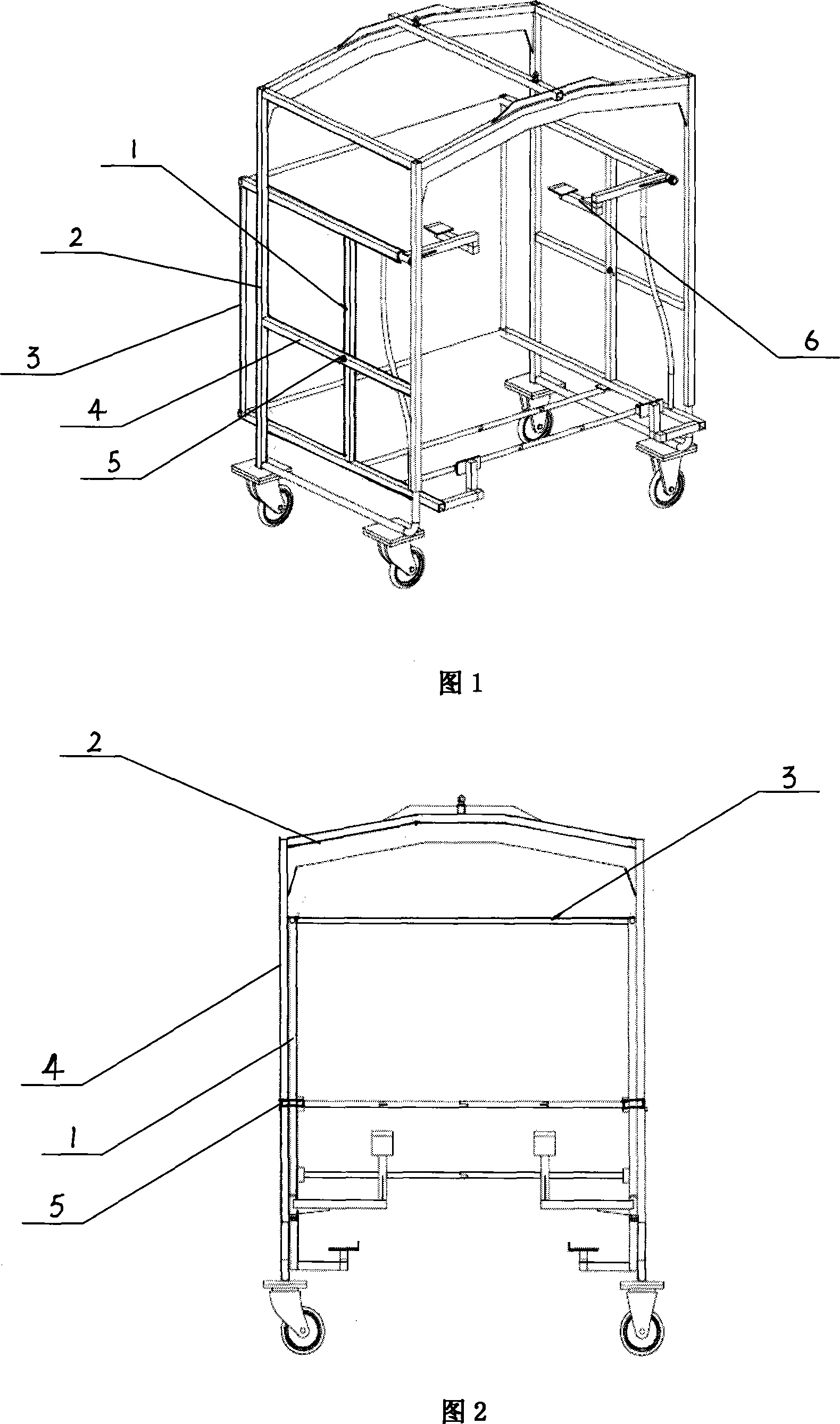

[0012] See accompanying drawing 1,2 shown.

[0013] The spreader frame of the present invention is provided with an inner spreader frame 3; the inner spreader frame beams 1 on both sides of the inner spreader frame 3 are respectively movably connected with the spreader frame beams 4 located in the outer spreader frame 2 through rotating shafts 5. The axes of the rotating shafts 5 on both sides are located on the same horizontal line. The inner spreader frame beam 3 and the spreader frame beam 1 connected by the rotating shaft 5 are perpendicular to each other. The upper or lower end of the inner spreader frame 3 is provided with a fixed bracket 6 .

[0014] The present invention adds a profiling inner spreader frame 3 in the spreader structure commonly used vertically into the water, and passes through the rotating shaft on the horizontal line passing through the center of gravity in the two outer surfaces of the spreader. Under the condition that the environmental condition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com