Chromizing method by using shaft furnace

A well-type furnace and chromizing technology, which is applied in the field of chromizing, can solve the problems of short service life, difficult quality assurance, and high production cost of box-type furnaces, and achieve the effects of saving direct production costs, high heat transfer efficiency, and saving electricity costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: During chromizing treatment, the chromizing tanks are placed in two layers in the pit furnace.

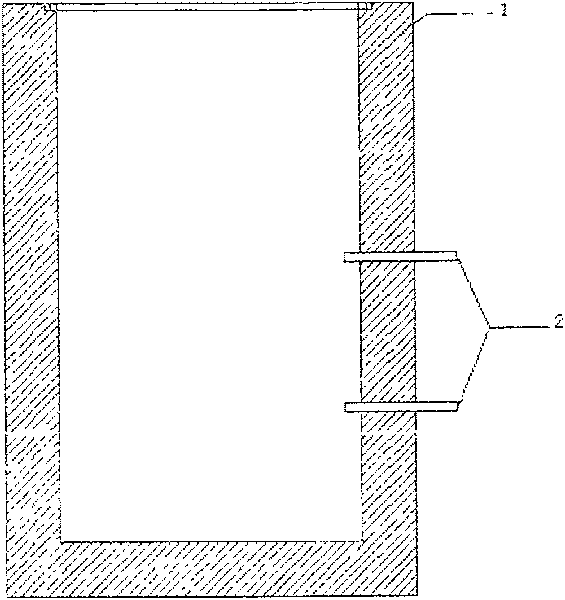

[0020] figure 1 In the schematic diagram of the furnace body section of the well-type furnace, the outer diameter of the well-type furnace is about 2200mm, the wall thickness of the insulation layer 1 is 340-360mm, the furnace height is 1840mm, and the effective clearance of the furnace: the inner diameter is about 1450mm, and the net height is about 1500mm. 2 thermocouples, about 600mm and 1200mm away from the bottom of the furnace, the total heating power is 100kW, the operating temperature is ≤950°C, the temperature rises rapidly, up to 10-15°C / min, and the heat preservation is good.

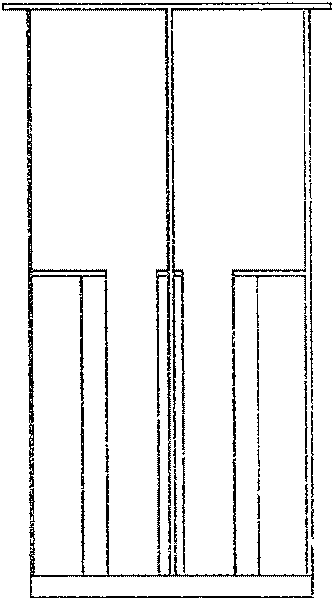

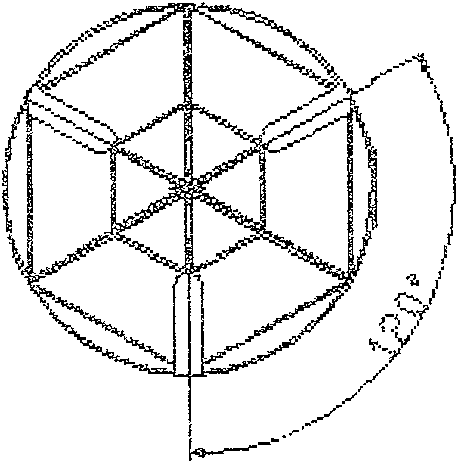

[0021] figure 2 , image 3 The protection ring and the support frame are shown. Considering the influence of the high temperature in the furnace, the support frame and the protection ring are welded together to increase the firmness. The distance between the protective rin...

Embodiment 2

[0030] Embodiment 2: During chromizing treatment, the chromizing tanks are placed in three layers in the pit furnace.

[0031] The pit furnace can increase the number of layers of chromizing tanks by increasing the size. Because the furnace body is enlarged, in order to ensure the furnace temperature, it is necessary to increase the number of temperature control thermocouples and increase the heating power accordingly.

[0032] The structure of the well-type furnace is still the same as in Example 1 when it is used in multiple layers, the outer diameter is about 2600mm, the wall thickness of the insulation layer is 340-360mm, the furnace height is 2440mm, and the effective headroom of the furnace: the inner diameter is about 1850mm, and the net height is about 2100mm. There are 3 thermocouples on the side, about 600mm, 1200mm, and 1800mm from the bottom of the furnace, the total heating power is 150kW, the operating temperature is ≤950°C, the temperature rises rapidly, up to 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com