Rooftop zoology heat insulation plate

A heat insulation board and ecological technology, applied in the direction of roof insulation materials, cultivation, application, etc., can solve the problems of difficult survival of plants in the special environment of the roof, long-distance transportation, maintenance and management, etc., to maintain perennial and long-term landscape and ecological effects, easy management, and simplified processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

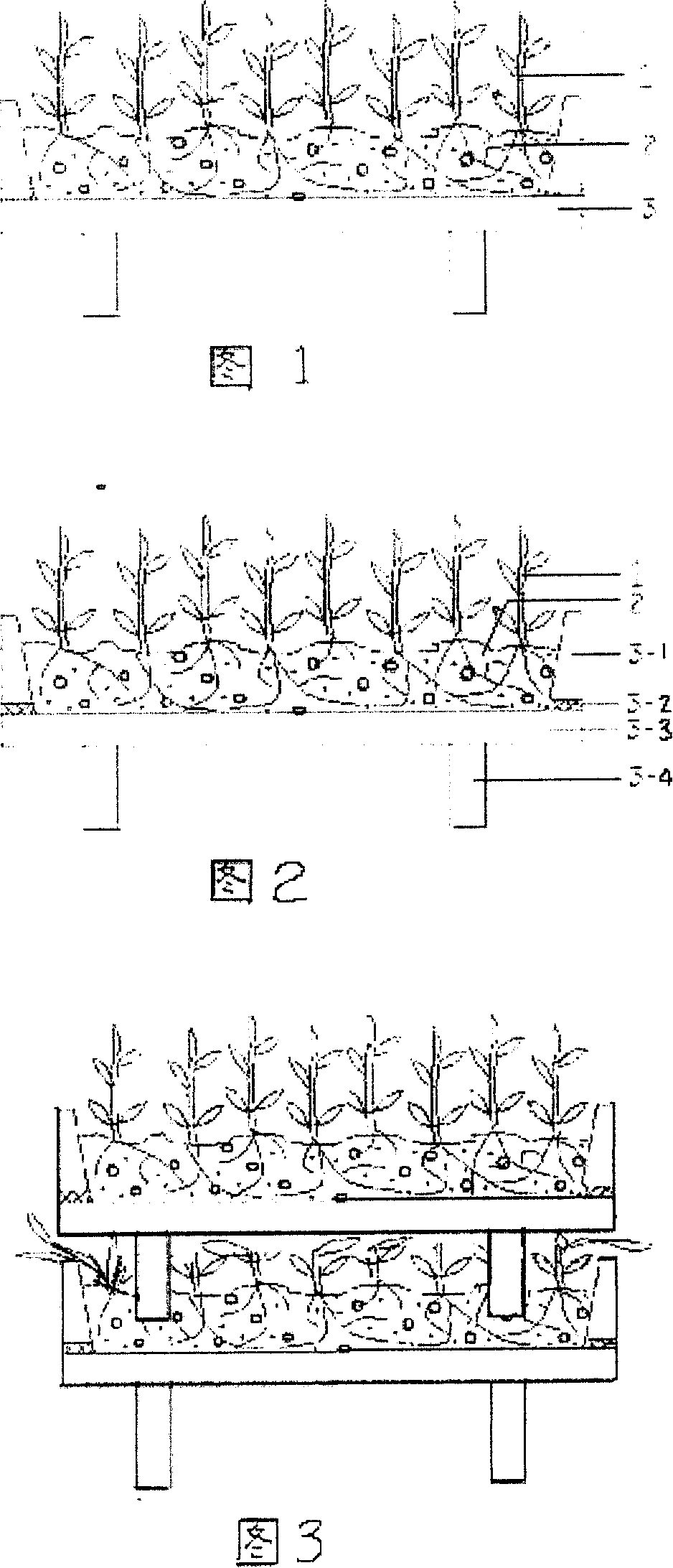

[0041] 1. Production of roof ecological heat insulation panel frame (as shown in Figure 1 and Figure 2)

[0042] ①Materials used: cement, hard plastic, glass fiber reinforced plastic, steel, take one of them;

[0043] ② Open the mold;

[0044] ③pressing or casting;

[0045] ④ Punch holes at the bottom of the side;

[0046] 5. Form the roof ecological heat insulation board frame (3), as shown in Figure 1 and Figure 2.

[0047] 2. Preparation of the growth base material layer (2) of the roof ecological heat insulation board

[0048] ①Organic materials: traditional Chinese medicine residue, food scraps, bagasse, coconut shell residue, textile fiber scraps, garbage organic soil, dead garden leaves, crop straw, fruit shells, livestock and poultry manure, etc.

[0049] Pretreatment of organic materials: Fully ferment organic materials such as traditional Chinese medicine residue, food scraps, bagasse, coconut shell residue, textile fiber scraps, garbage organic soil, dead garden...

Embodiment 2

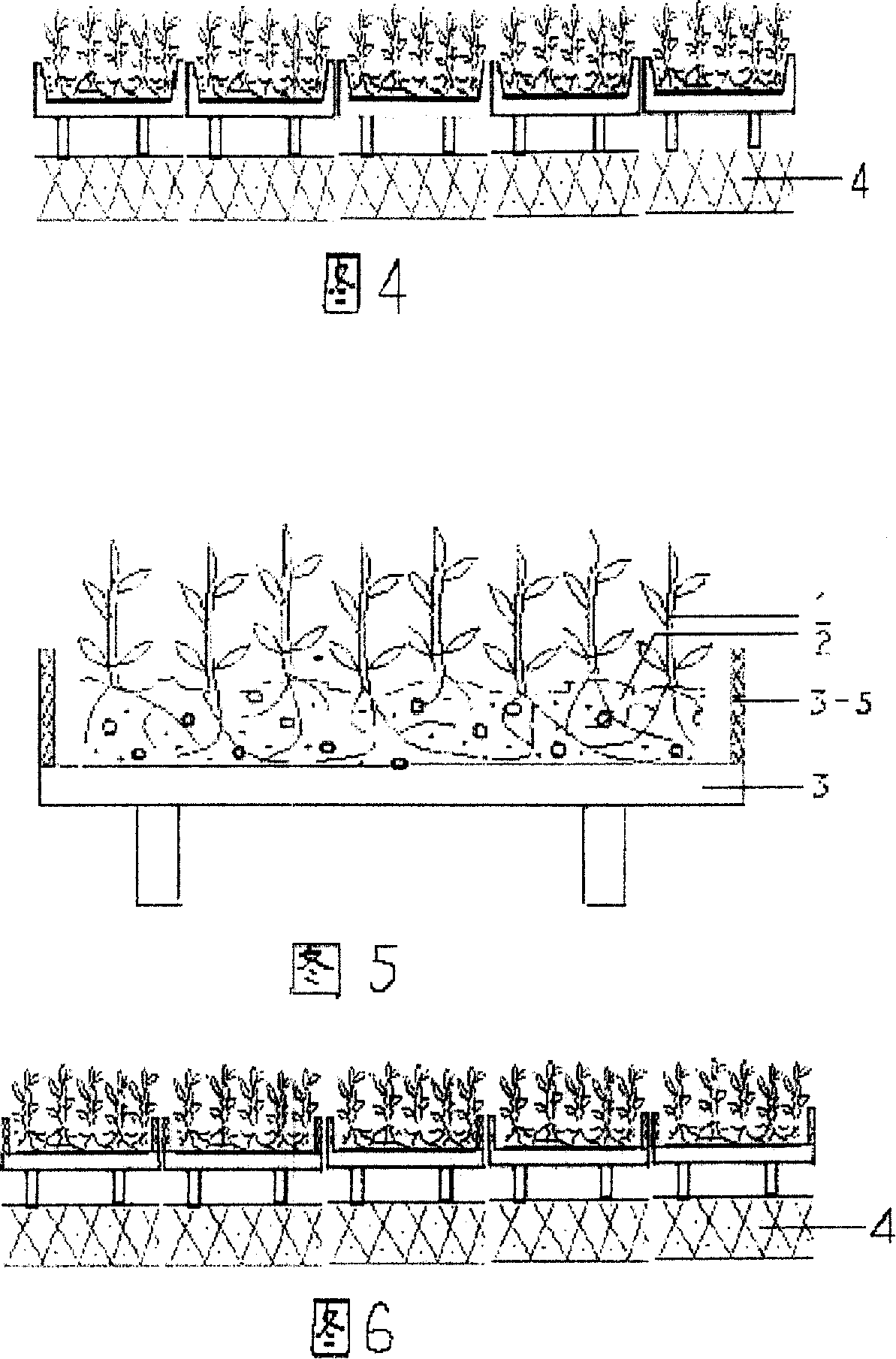

[0066] 1. Production of roof ecological heat insulation panel frame (as shown in Figure 5)

[0067] ①Materials used: cement, hard plastic, glass fiber reinforced plastic, steel, take one of them;

[0068] ② Open the mold, without the edge:

[0069] ③pressing or casting;

[0070] 4. put the net-shaped edge (3-5) around the base plate (3-3) of the roof ecological heat insulation board frame;

[0071] 5. Form the roof ecological heat insulation board frame (3), as shown in Figure 5.

[0072] 2. Prepare the growth base layer of the roof ecological heat insulation board

[0073] 2. With embodiment 1.

[0074] 3. The cultivation of the living plant layer (1) of the roof ecological heat insulation board is the same as 3. of embodiment 1.

[0075] 4. Placement of roof ecological heat insulation board roof

[0076] ① Stack the roof ecological heat insulation panels as shown in Figure 3, transport and lift them to the roof.

[0077] ② Place the roof ecological heat insulation boa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com