A cooling system for permanent magnetic generator

A permanent magnet generator and cooling system technology, which is applied in the direction of machines/engines, cooling/ventilation devices, electrical components, etc., can solve the problems of reducing the service life of motors, reducing the power of permanent magnet motors, and thermal demagnetization of permanent magnets, etc., to achieve extended The effect of service life, reducing heat conduction, and smooth air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

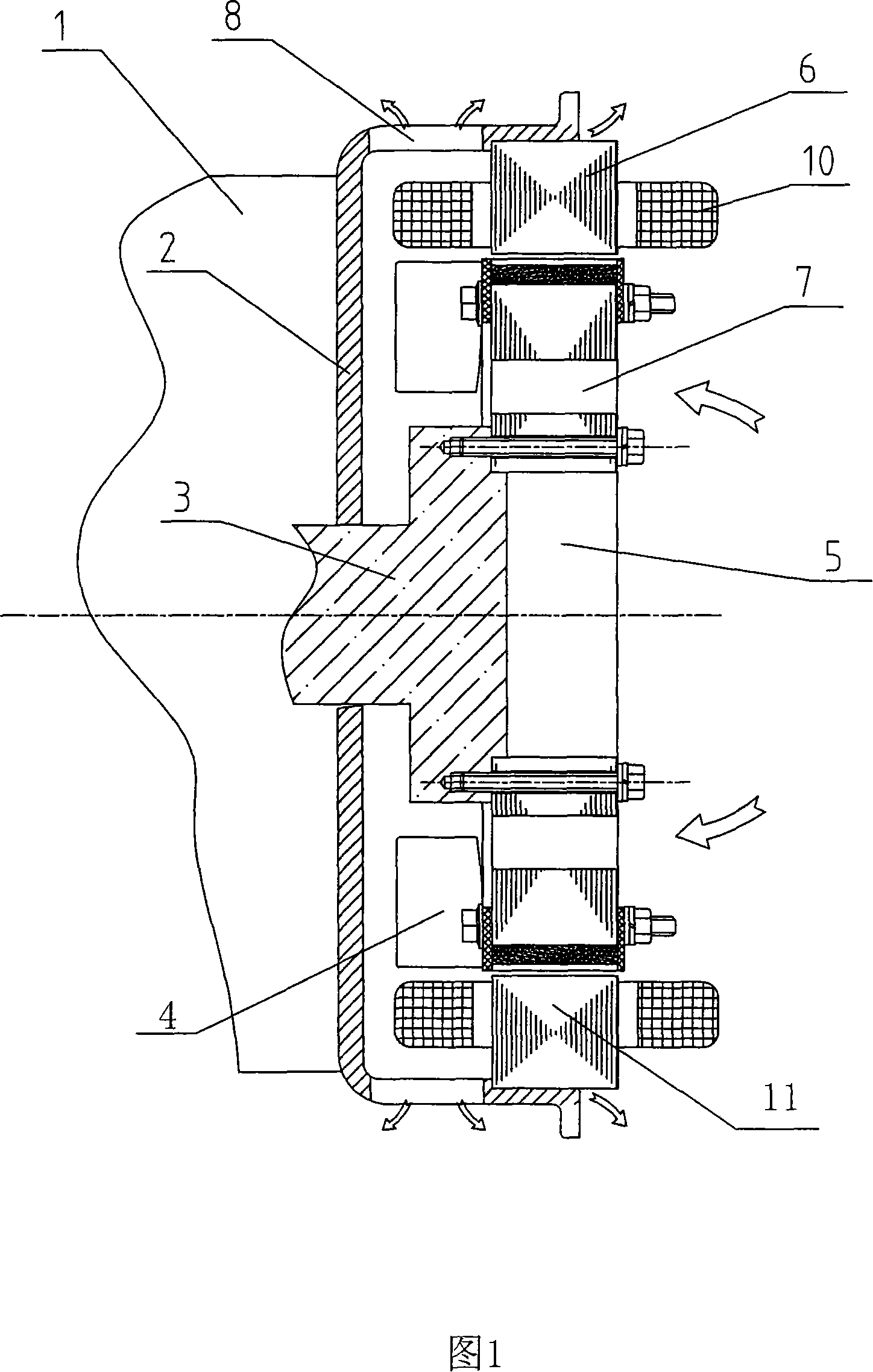

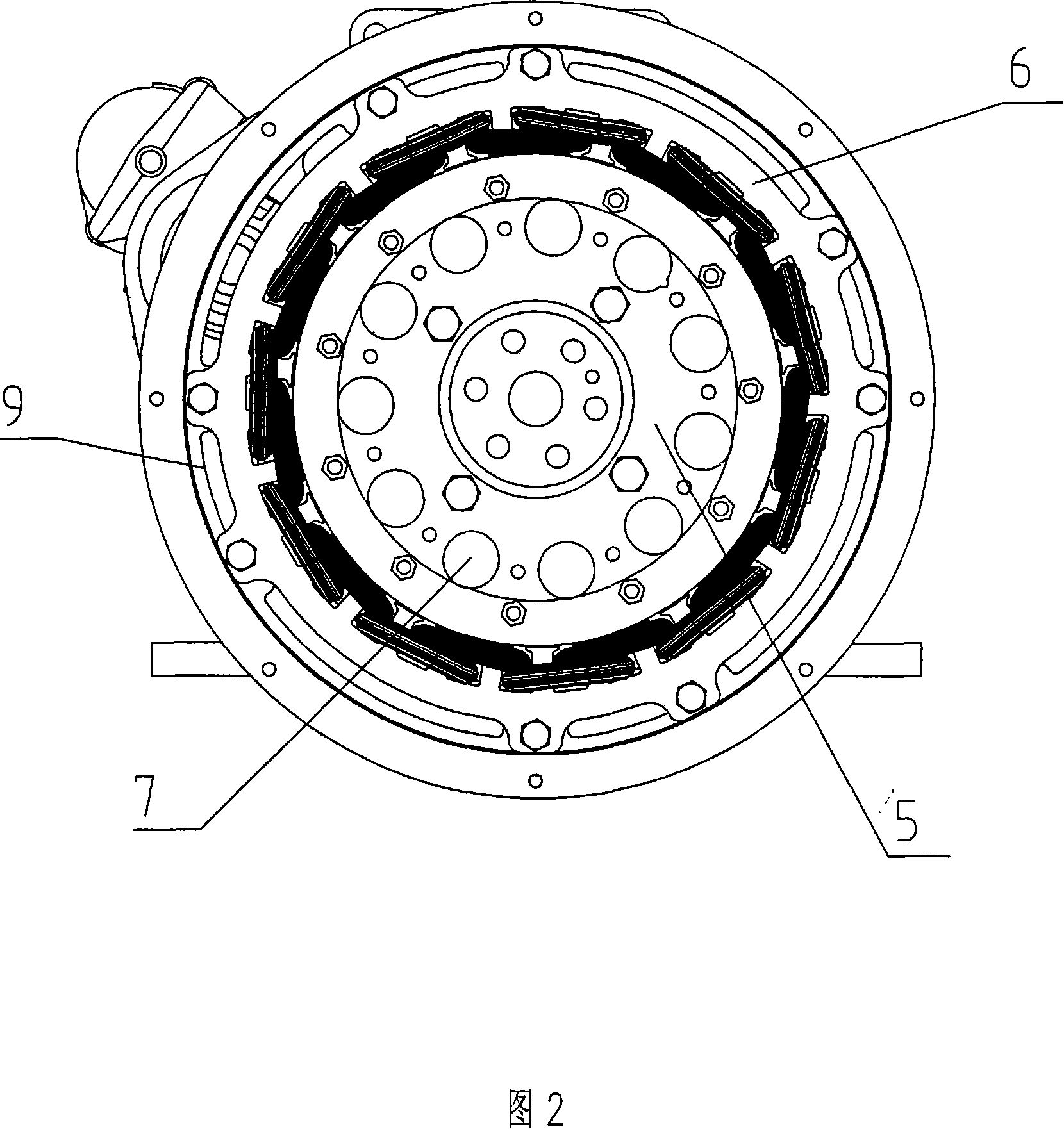

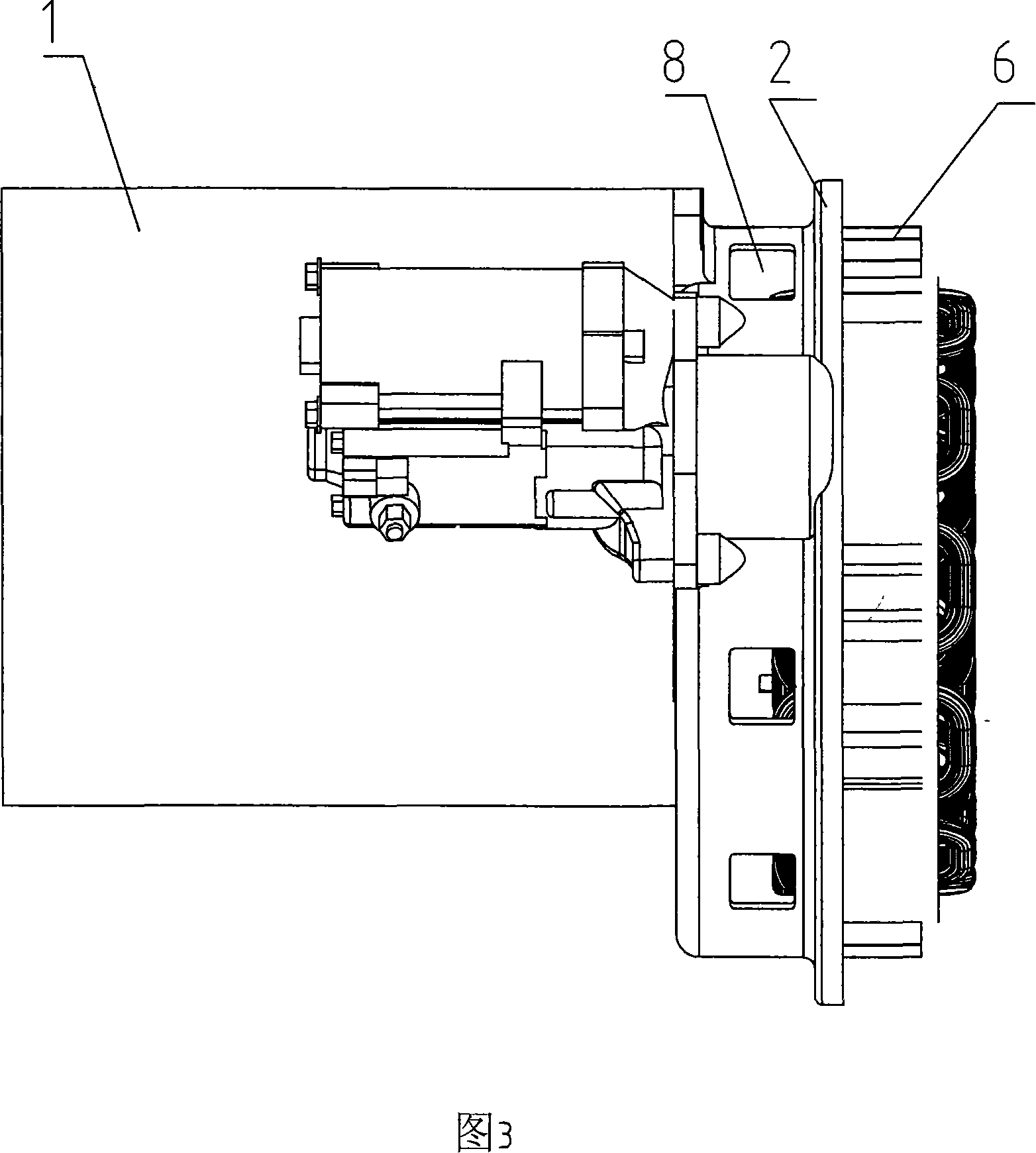

[0016] The present invention mainly consists of engine 1, engine flywheel housing 2, engine crankshaft 3, fan blade 4, permanent magnet generator rotor 5, permanent magnet generator stator 6, air inlet hole 7, exhaust hole 8, exhaust hole 9, stator Composed of coil 10 and permanent magnet generator 11 etc.

[0017] The present invention is mainly made up of engine 1, engine flywheel casing 2 and permanent magnet generator 11, and permanent magnet generator stator 6 is installed on the engine flywheel casing 2, leaves gap between engine flywheel casing 2 and permanent magnet generator stator 6, so The outer diameter of the above-mentioned engine flywheel housing 2 is provided with at least two or more exhaust holes 8 . Said engine flywheel housing 2 and the groove provided on the outer diameter of the permanent magnet generator stator 6 form at least t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com