Molded parts with mixed material surface areas and processes for their production

A surface area, product technology, applied in the direction of household appliances, other household appliances, coatings, etc., can solve the problem of thin shell parts that do not allow the use of concealment and protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

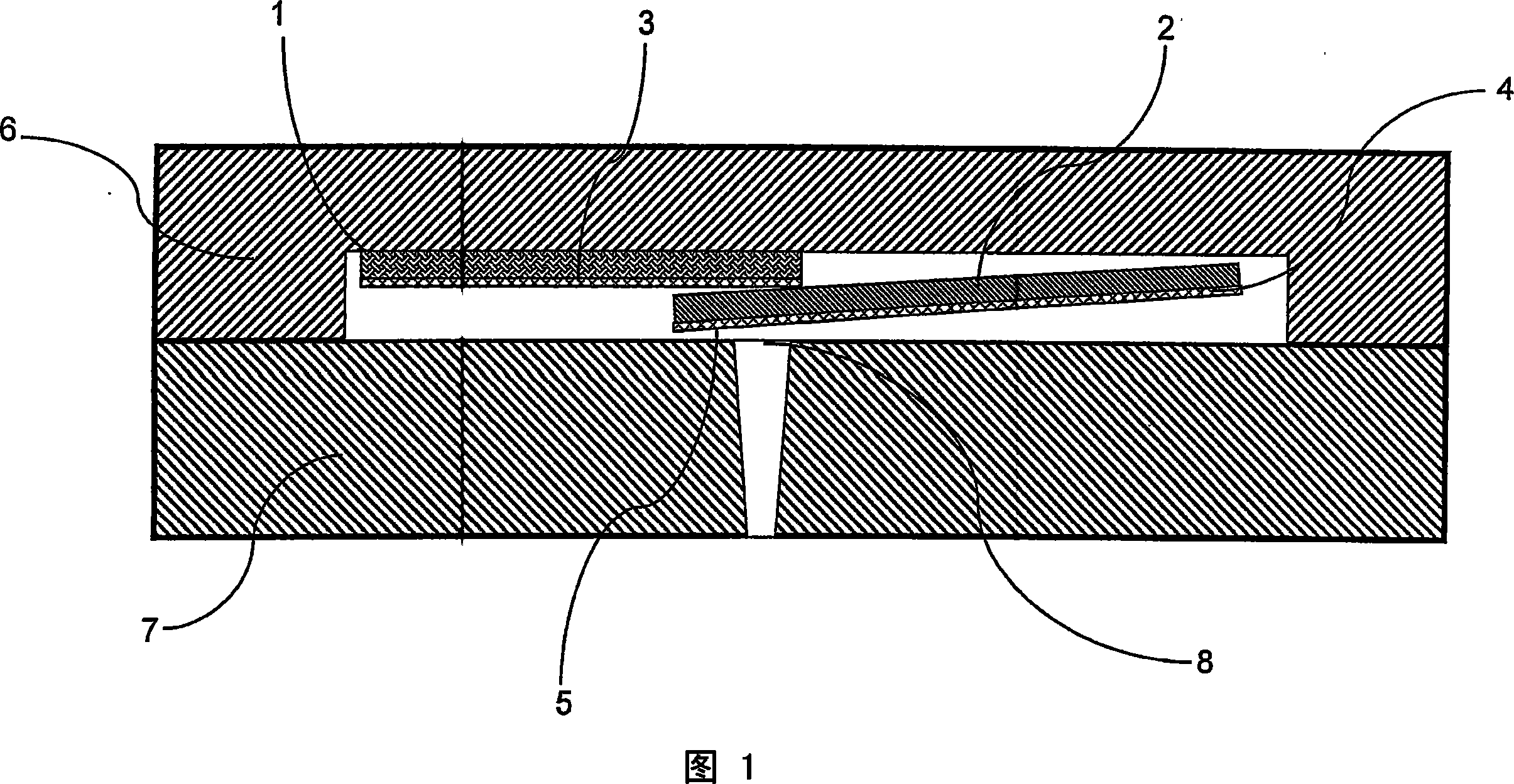

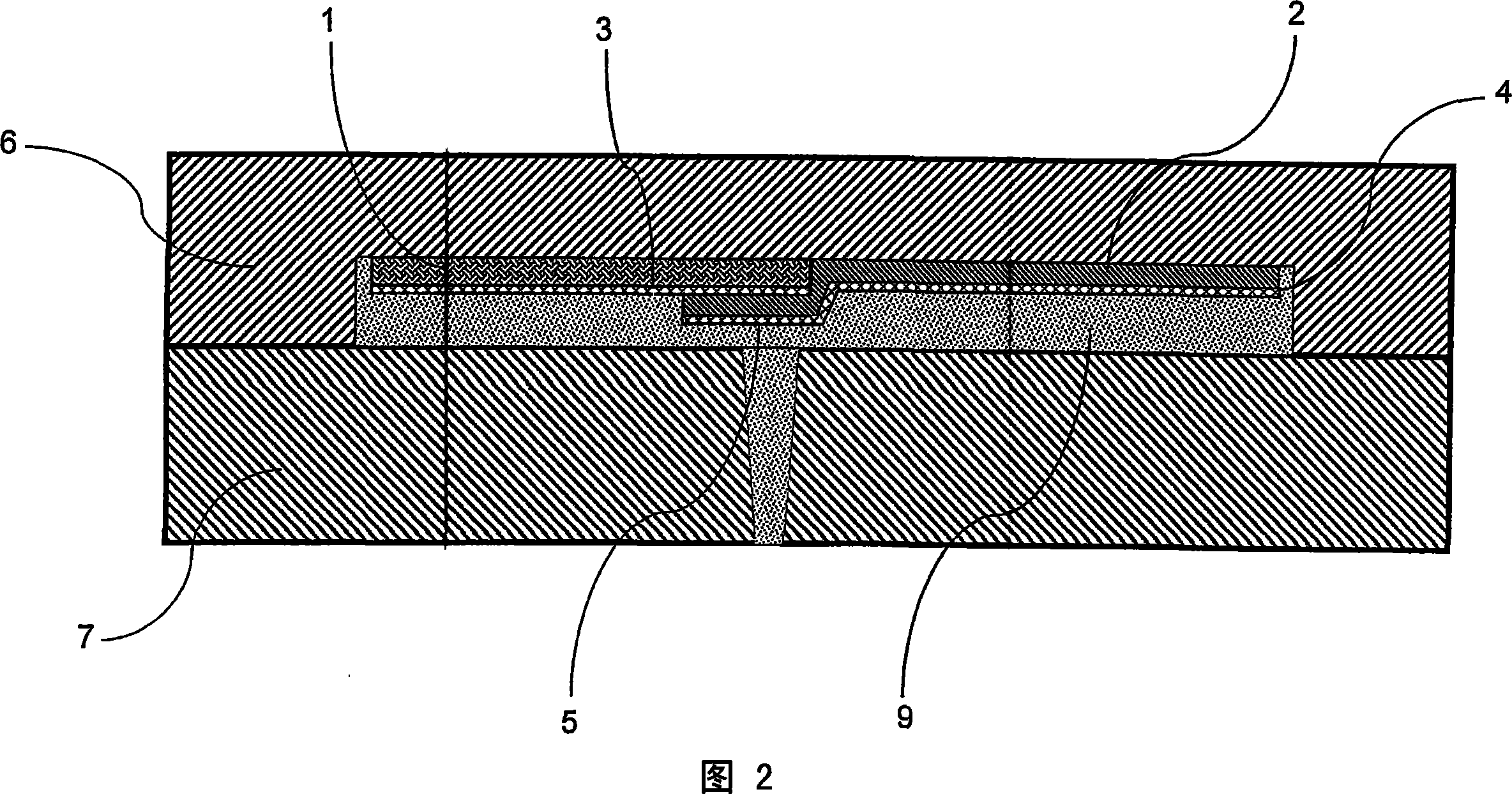

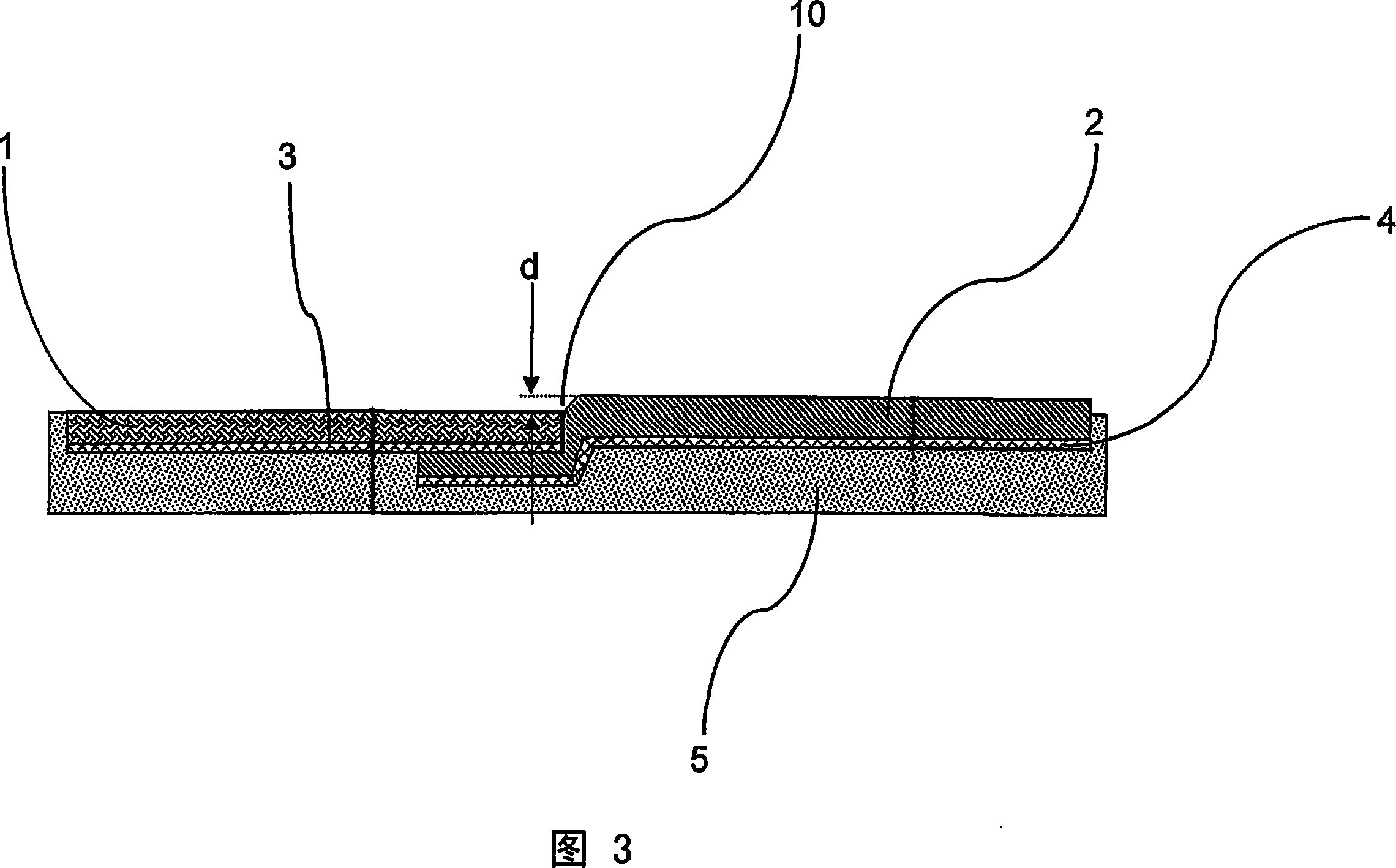

[0058] In an embodiment of the products and methods of the present invention (Experiment 1), a molded polycarbonate substrate was provided with a combination of metal and suede surface areas, wherein the metal was the first material and was secured in strips throughout the suede. on the surface area of the upper leather. The metal in this example is anodized aluminum. The metal has a thickness of 0.006 inches (0.15 millimeters) and is laminated with a thermoplastic bonded bilayer film ("2-ply") with polyethylene (PE) on one side and polyamide (PA) on the other . This adhesive film has 10 grams (gm) PE / square meter ( / m 2 ) and 40 g PA / m 2 , with a total density of 0.96 grams / cubic centimeter (gm / cm 3 ), with a melting point ranging from 120 to 125°C. The film was laminated to the metal using a flatbed laminator set at 135°C and 80 pounds per square inch (psi) (0.55 MPa) lamination pressure with the PE side facing the metal. The metal is cut into desired surface area sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com