Tobacco flavor compensating agent used for low tar filter tip rod and uses thereof

A flavor compensation and filter rod technology, which is applied in the field of tobacco, can solve the problems of insignificant flavor supplement effect and low-tar cigarette flavor loss, and achieve the effects of compensating for flavor loss, low cost, and increasing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The tobacco flavor compensator of the present invention is made up of the following composition of proportion: 1500 grams of tobacco extract, 5 grams of furfural, 2 grams of 5-methyl-furfural, 3-ethyl-2-hydroxyl-2-cyclopentene -1-ketone 5 grams, methyl palmitate 5 grams, solanone 5 grams, dihydroactinolactone 3 grams, damascenone 5 grams, macrostigmatrienone 10 grams, pyridine 3 grams, 2-methyl Base-pyridine 3 grams, acetic acid 30 grams, propionic acid 5 grams, benzoic acid 3 grams, palmitic acid 50 grams.

[0021] The above-mentioned components are configured into a flavor compensator (viscous liquid), and the tobacco flavor compensator is directly added to the plasticizer triacetin in a ratio of 15-25% to make a triacetate of the tobacco flavor ingredient additive The glyceride solution is added to the filter stick during the forming process of the filter stick to make a flavor-enhancing filter stick, which is used in the production of low-tar cigarettes according to...

Embodiment 2

[0023] The tobacco flavor compensator of the present invention is composed of the following ingredients in proportions: 1 kilogram of tobacco extract, 1 gram of 5-methyl-furfural, 3-ethyl-2-hydroxyl-2-cyclopenten-1-one 2 grams, methyl palmitate 2 grams, solanone 2, damascenone 2 grams, macrostigmatrienone 3 grams, 2-methyl-pyridine 1 grams, acetic acid 10 grams, palmitic acid 10 grams.

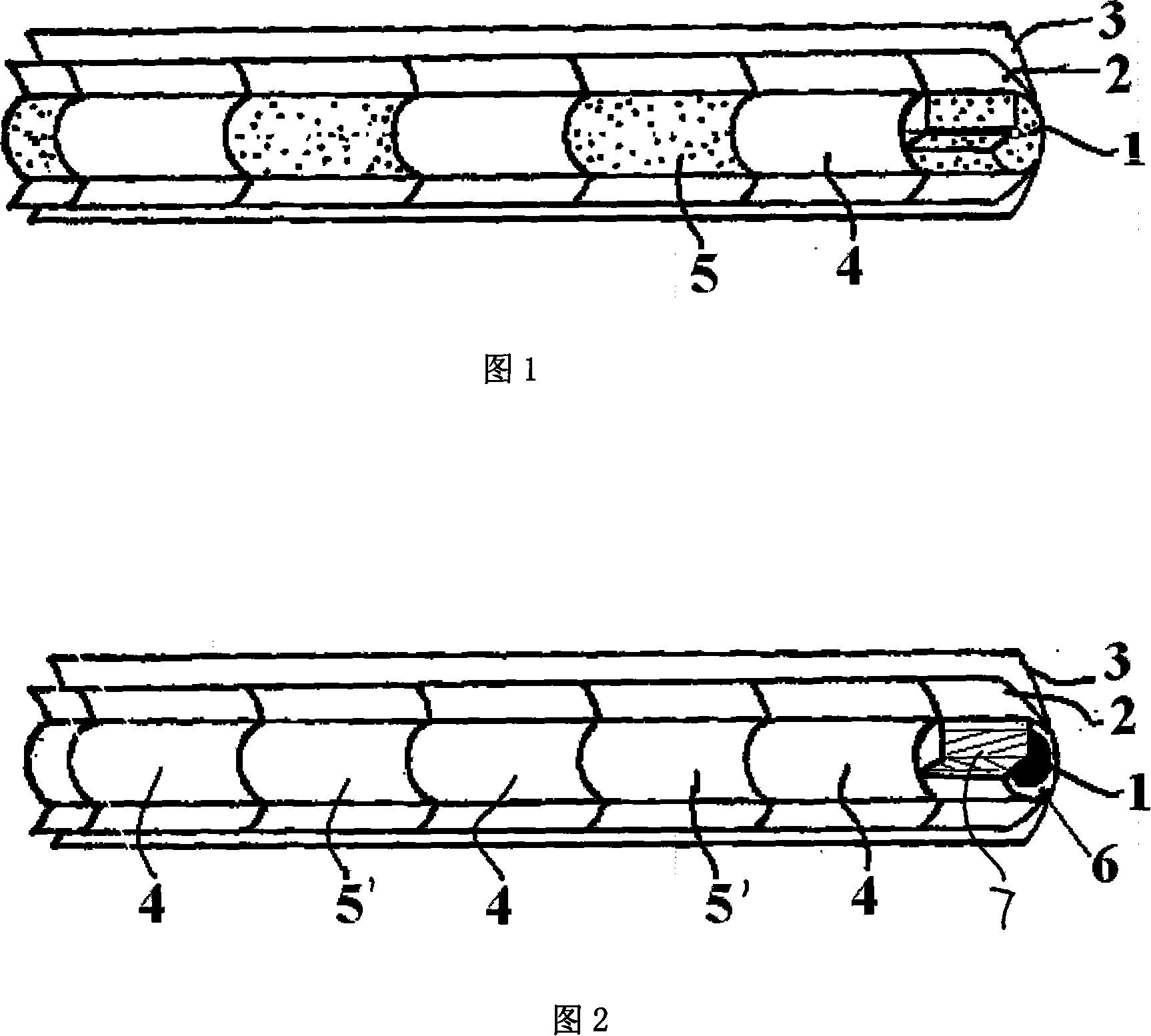

[0024] The above components are configured into a liquid flavor compensator, and the flavor compensator is adsorbed by an adsorbent to make a multi-component composite filter tip. The adsorbent used can be activated carbon, porous ceramics, diatomaceous earth, porous polysiloxane, nanoparticles, medical stone and other materials, and can also be common fiber materials. Adsorbents that are adsorbed with tobacco flavor component additives can be dispersed in a certain section of the multi-component composite filter stick, as shown in Figure 1: the binary flavor compensating filter element 1 is a...

Embodiment 3

[0026] The tobacco flavor compensator of the present invention is made up of the following composition of proportion: 1 kilogram of tobacco extract, 2 grams of furfural, 1 gram of 5-methyl-furfural, 3-ethyl-2-hydroxyl-2-cyclopentene -1-ketone 2, methyl palmitate 2 grams, solanone 2 grams, damascenone 2 grams, macrostigmatrienone 3 grams, 2-methyl-pyridine 1 grams, acetic acid 10 grams, palmitic acid 10gram.

[0027] The above components are configured into a liquid fragrance compensator, and after the fragrance compensator is adsorbed by an adsorbent (such as porous ceramics), a multi-component composite filter tip is made. As shown in Figure 2: it consists of a binary compound flavor compensating filter element 1, an inner wrapping layer 2 and an outer wrapping layer 3. Binary aroma compensating filter element 1 is formed by alternating connection of cellulose acetate segments 4 and cellulose acetate plus porous ceramic column segments 5', the inner wrapping layer 2 wraps on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com