Welded structure of quenching and tempering steel alloy with middle carbon and low-alloy steel and method thereof

A low-alloy steel and welding method technology, which is applied to the welding structure of medium-carbon quenched and tempered alloy steel and low-alloy steel, and the welding field of medium-carbon quenched and tempered alloy steel and low-alloy steel, which can solve weld toe cracks, structural failure, etc. problems, to achieve good mechanical properties, improve component performance, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

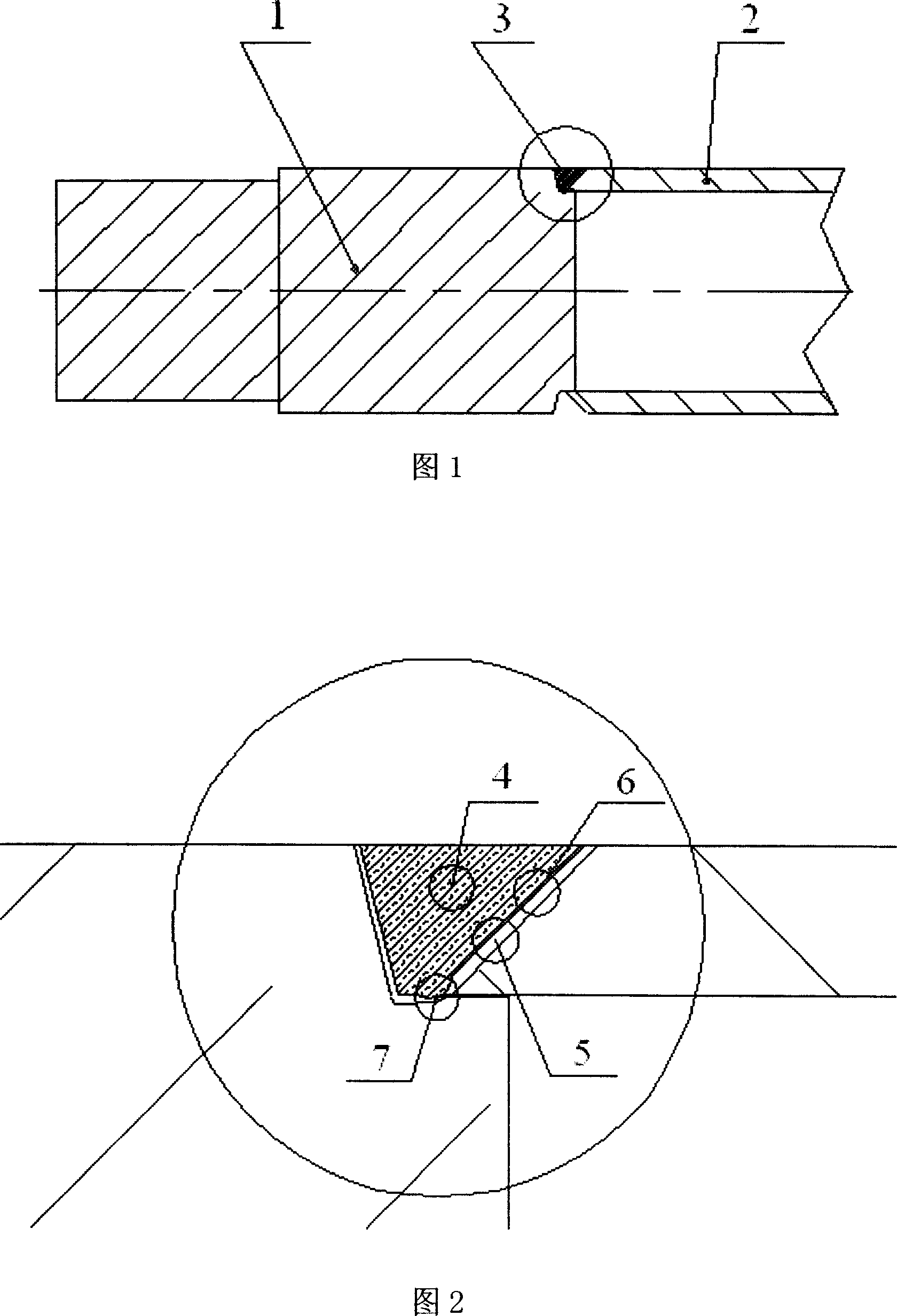

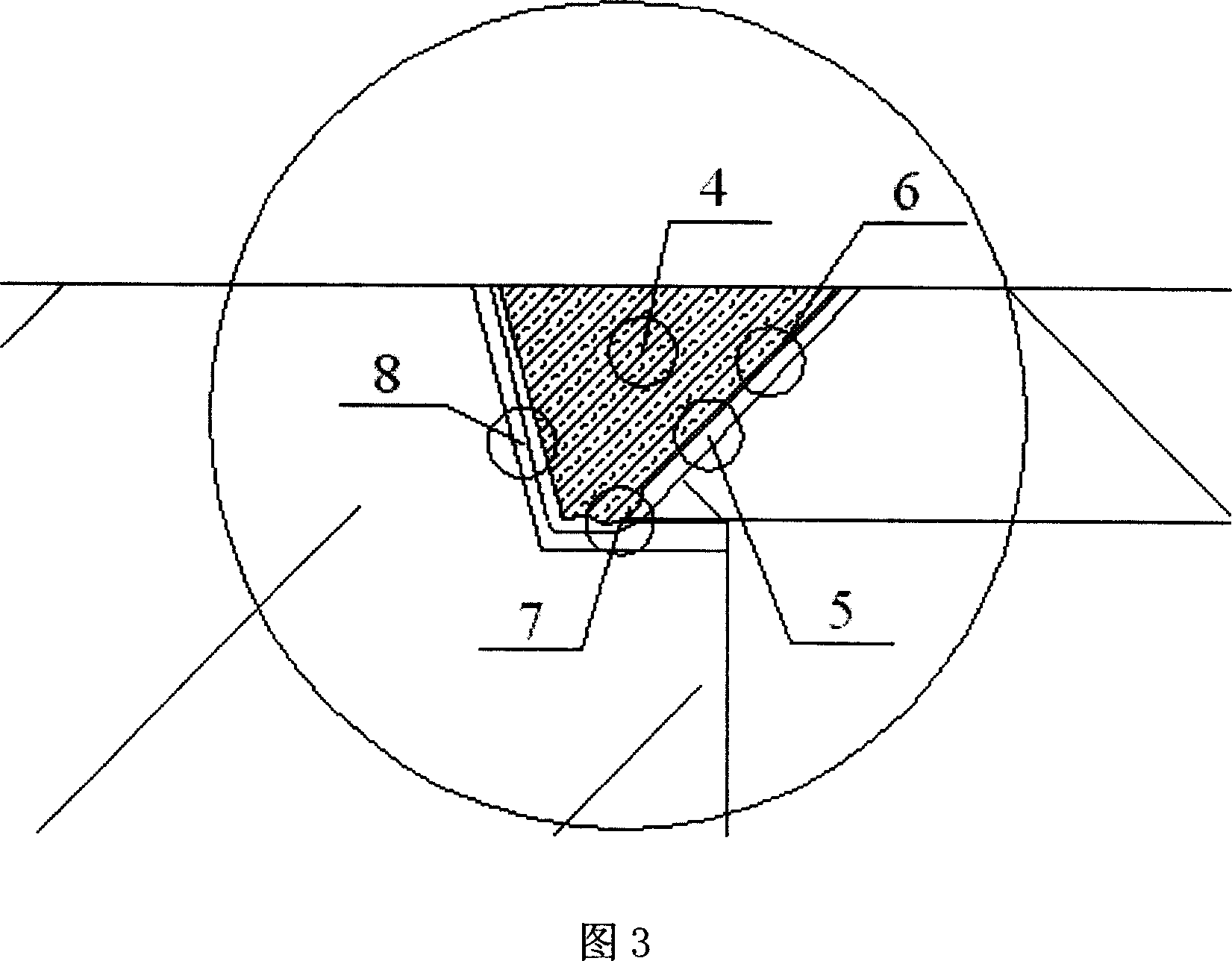

[0018] The welded structure of medium carbon quenched and tempered alloy steel and low alloy steel of the present invention is shown in Figure 3, comprises medium carbon quenched and tempered alloy steel part, low alloy steel part and welded joint, and described welding part is filled with welding meat 4, in the There is also a transition layer 8 between the welding meat and the medium carbon quenched and tempered alloy steel and the welding meat and the low alloy steel. The composition of the transition layer includes, by weight, carbon≤0.12%, manganese≤1.60%, silicon≤0.75%, sulfur≤0.035%, phosphorus≤0.04%, and the rest is iron. A groove is provided at the contact position between the medium-carbon quenched and tempered alloy steel part and the low-alloy steel part, and the welding part composed of the grooves on both sides is filled with the weld metal 4 . On both sides of the interface between the welded meat 4 and the groove, there will be a heat-affected zone 5. In the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com