Light source fixing structure of backlight component

A technology for a backlight assembly and a fixed structure, which is applied in optics, nonlinear optics, instruments, etc., can solve the problems of poor heat dissipation and insufficient structural strength of the flexible printed circuit board 42

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

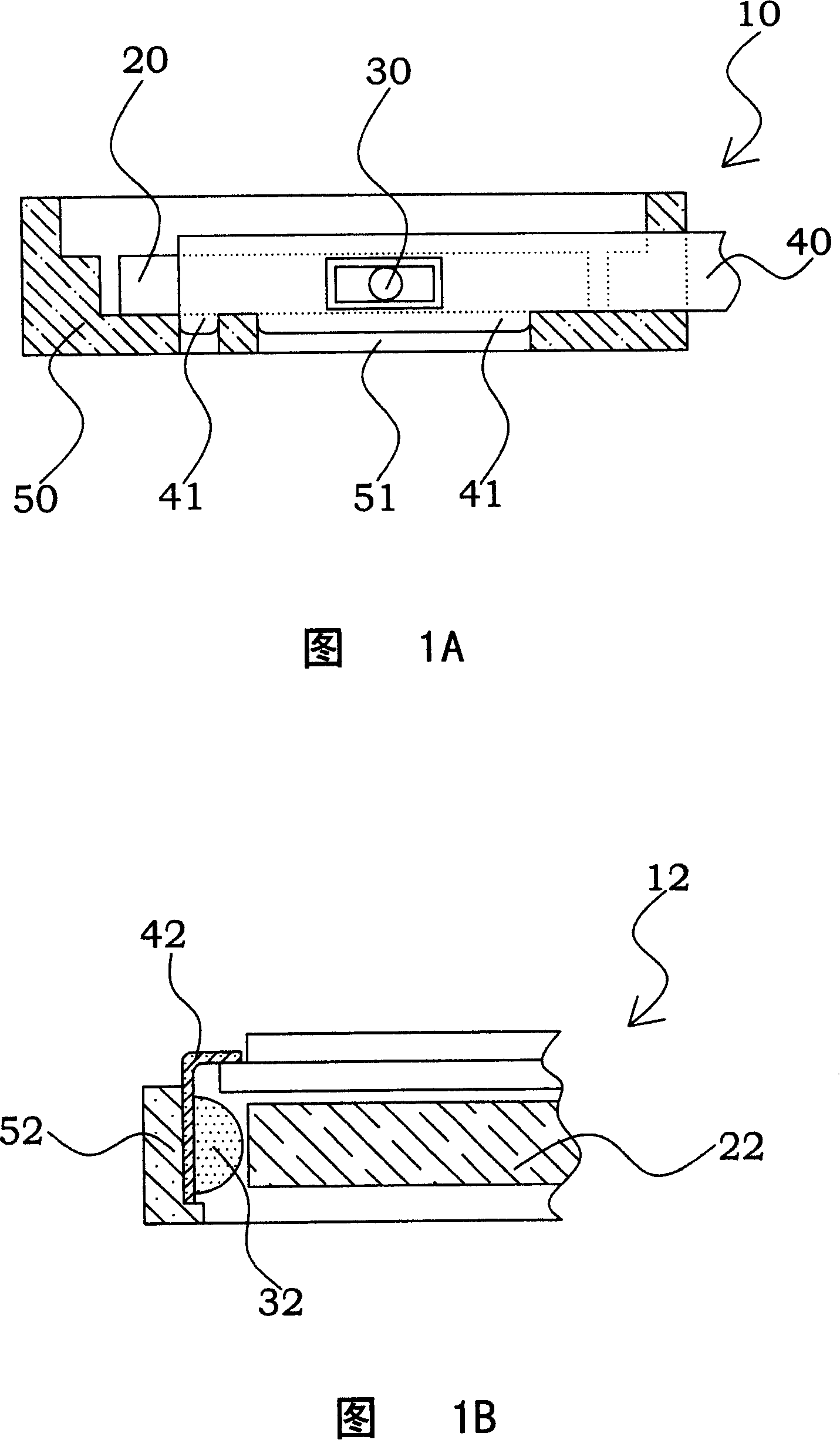

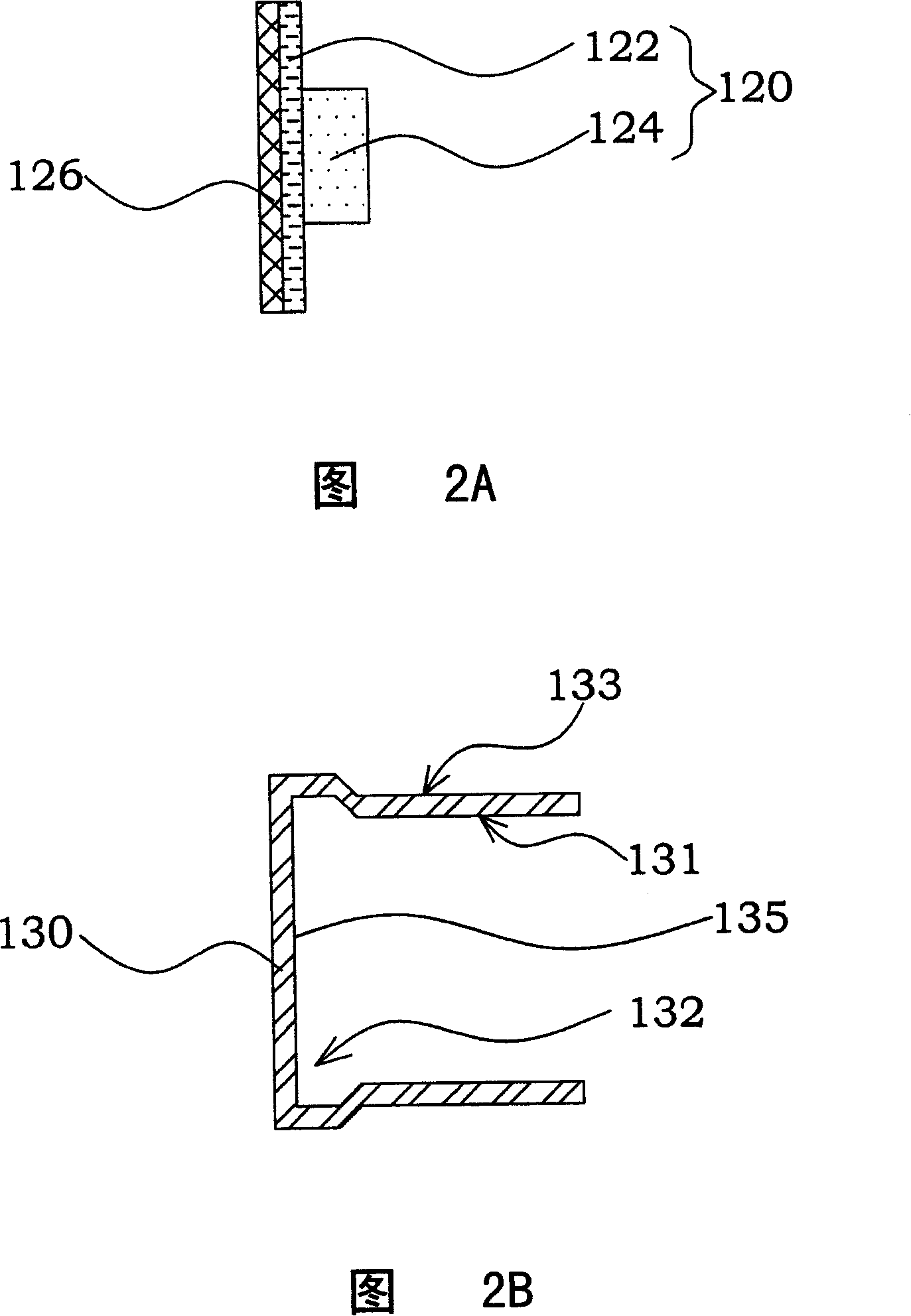

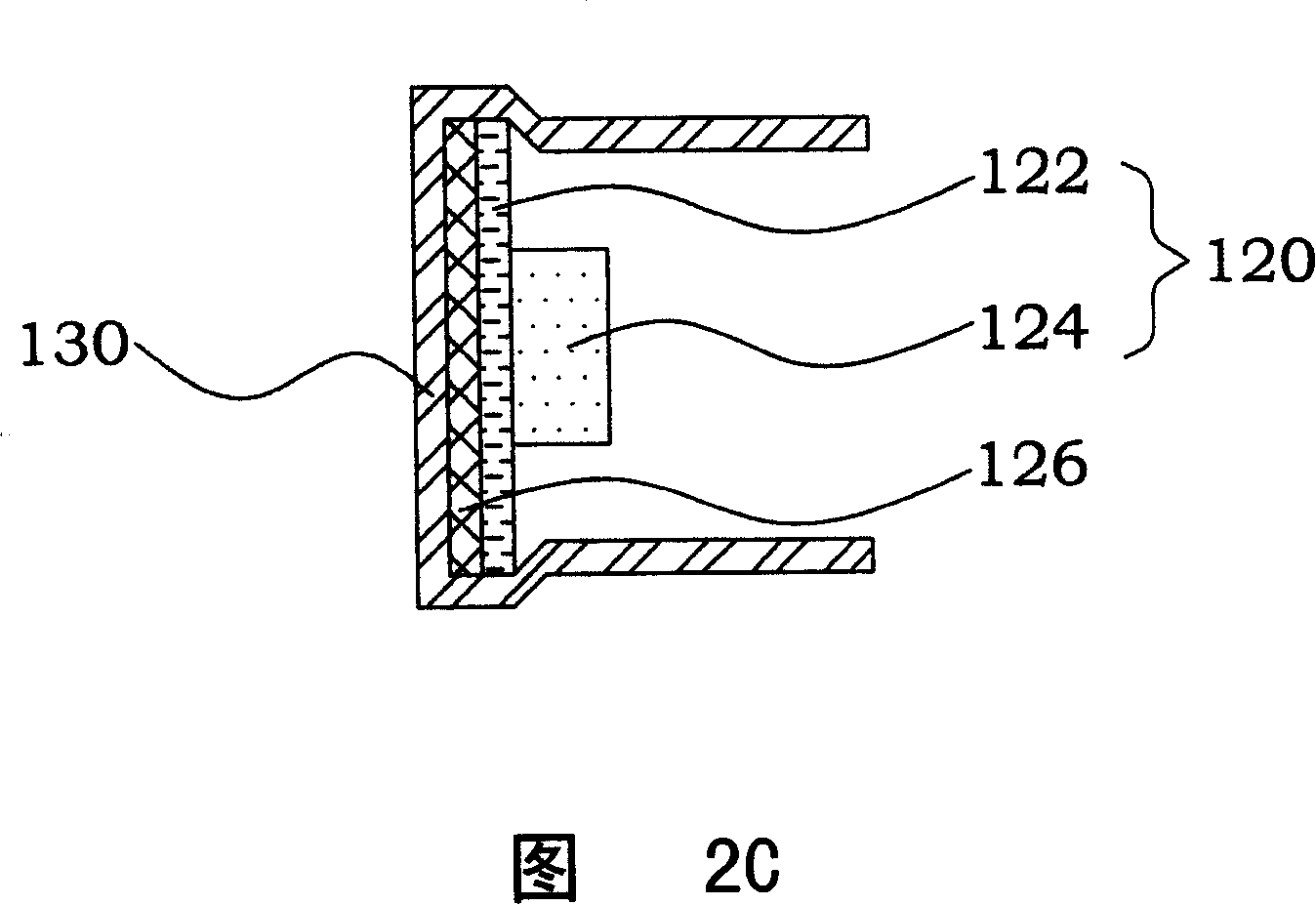

[0021] The light source fixing structure of the backlight assembly of the present invention will be described below using several preferred embodiments. First, please refer to FIG. 2A , which is a cross-sectional view of the strip-shaped light emitting elements of the backlight assembly according to the first embodiment of the present invention. As shown in the figure, the strip-shaped light-emitting element 120 includes a substrate 122 , such as a printed circuit board, and at least one light-emitting diode 124 fixed on one side of the substrate 122 by a conventional method. In one embodiment, a highly conductive metal substrate 126 , such as an aluminum substrate or a copper substrate, is attached under the substrate 122 to increase the heat dissipation of the strip-shaped light emitting element 120 . The position where the LED 124 is fixed on the substrate 122 is not limited. Next, please refer to FIG. 2B, the cover body 130 includes a metal with good heat dissipation, suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com