Piezoelectric ceramic driving circuit used for optical fiber stress adjustment

A piezoelectric ceramic drive, optical fiber stress technology, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problem of slow input voltage changes and achieve good dynamic Response characteristics, the effect of good follow-up zoom function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 Circuit structure and working principle of the present invention

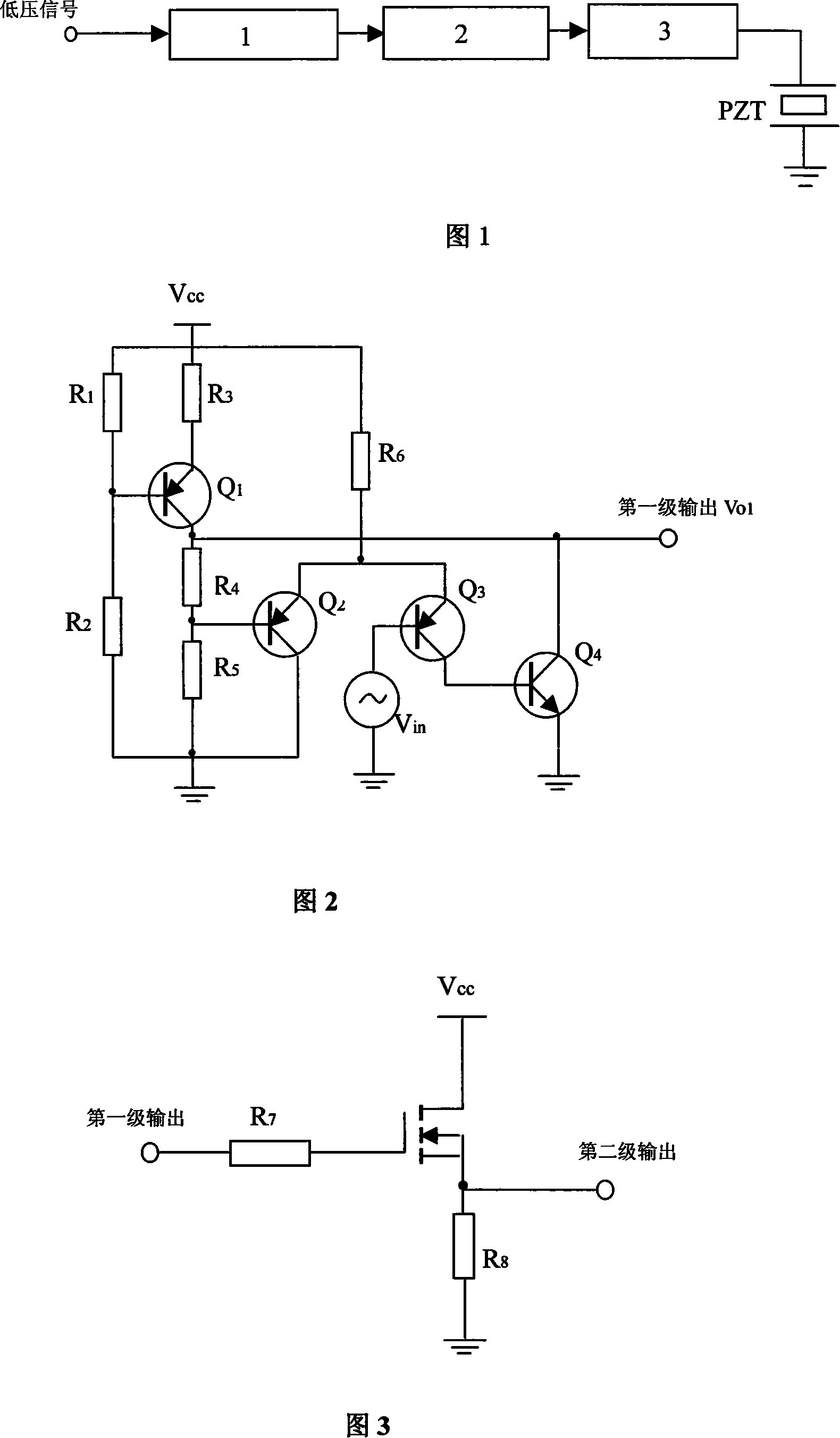

[0041] As shown in Figure 1: the piezoelectric ceramic (PZT) drive circuit applied to optical fiber stress regulation includes a voltage amplifier circuit (1), a power amplifier circuit (2) and a discharge loop circuit (3).

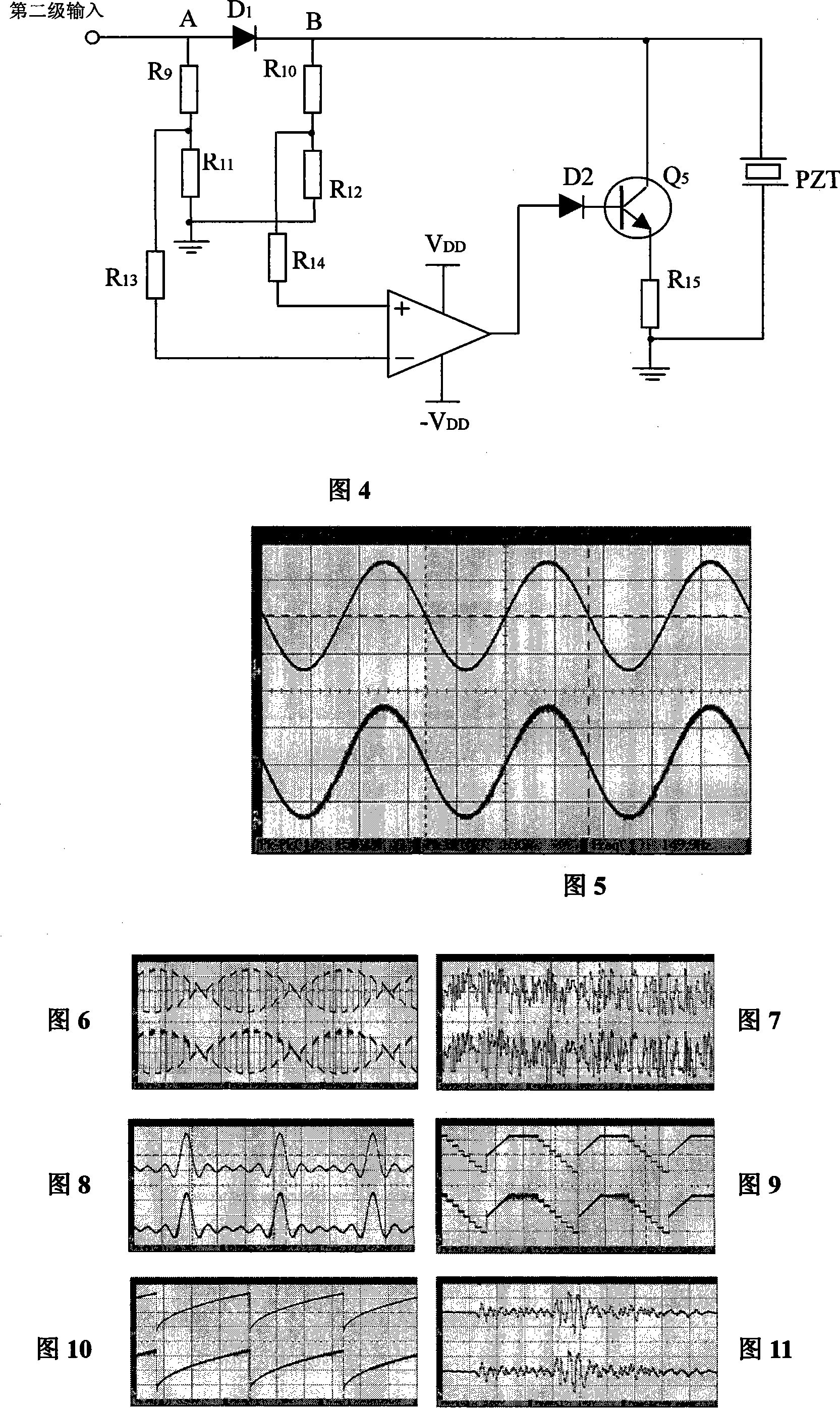

[0042] The voltage amplification stage circuit (1) is shown in Figure 2: Q 1 and resistor R 1 , R 2 , R 3 Consists of a constant current source circuit, where the transistor Q 1 base and resistor R 1 , R 2 connected, the emitter through a resistor R 3 with power supply V cc connection, R 2 Connect to ground, R 1 the other end with V cc connect. Resistance R 4 , R 5 , R 6 with transistor Q 2 , Q 3 Form a feedback comparison loop, where the transistor Q 2 , Q 3 For two PNP transistors with the same parameters, Q 2 , Q 3 The emitter is connected through resistor R 6 with power supply V cc connect, Q 2 Base connection resistance R 4 , R 5 , resistor...

Embodiment 2

[0049] Embodiment 2 A group of specific circuit parameters

[0050] A group of specific circuit parameters are provided below, but the circuit parameters of the present invention are not limited to this group:

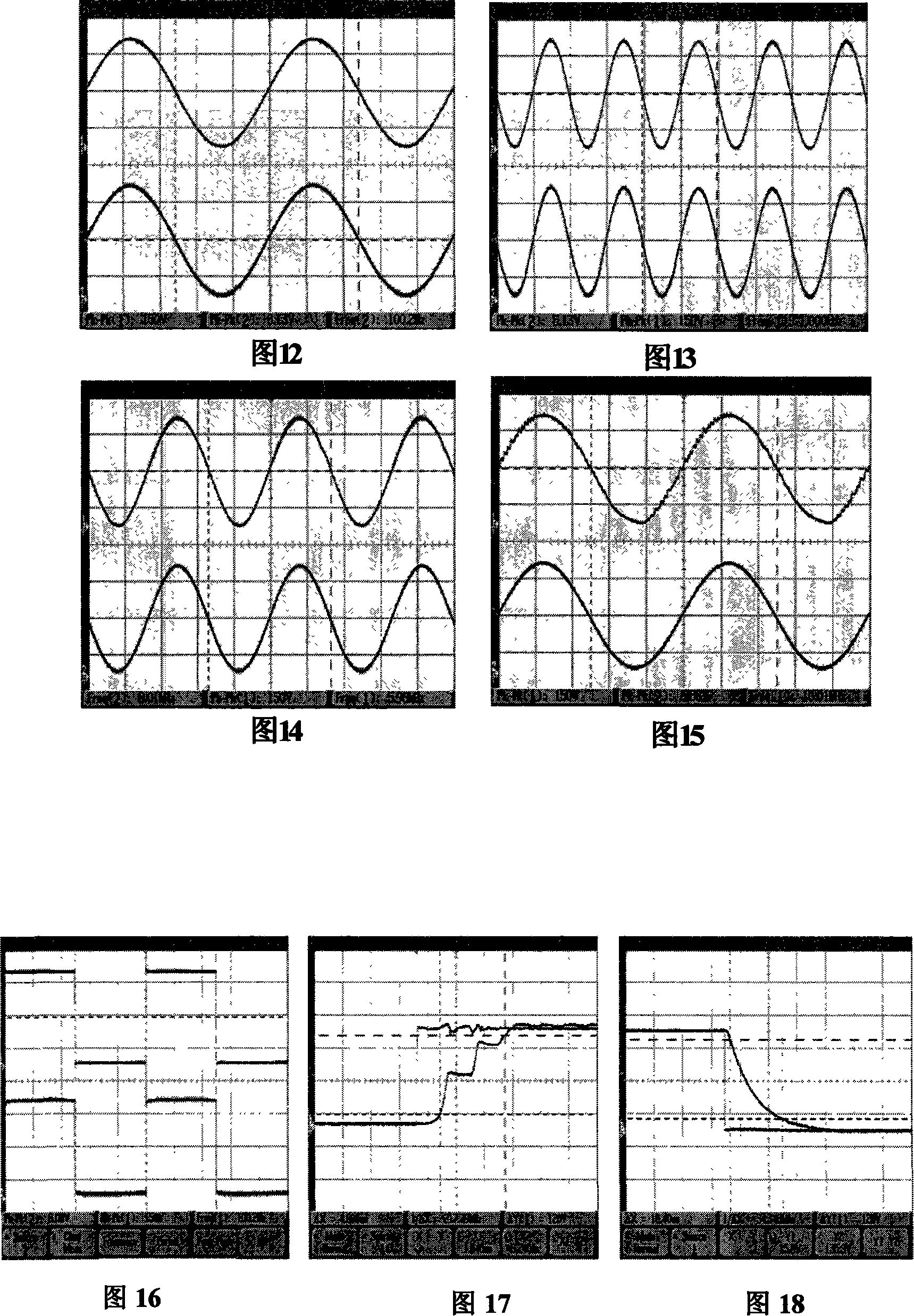

[0051] The preferred circuit parameters of the present invention are set as follows: V CC =230V, comparator operational amplifier voltage V DD = 5V, R 1 =300KΩ, R 2 = 400KΩ, R 3 =6.51KΩ, R 4 = 30KΩ, R 5 = 1.2KΩ, R 6 =150KΩ, R 7 = 1.0KΩ, R 8 = 20KΩ, R 9 =R 10 = 1.0MΩ, R 11 =R 12 =R 13 =R 14 = 10KΩ, R 15 = 10Ω.

Embodiment 3

[0052] Embodiment 3 The example of the driving circuit voltage magnification research of the present invention

[0053] The voltage magnification of the drive circuit of the present invention is studied using the circuit parameters set in Example 2. The amplified waveform of the sinusoidal input voltage shown in Figure 5 is obtained, where the upper part of the figure is the output voltage V 01 waveform, below is the input voltage V in waveform. input signal V in The amplitude of is 5.82V, and the signal frequency is f=150Hz. Therefore, it can be concluded that the circuit voltage magnification A= 150 / 5.82 =25.77≈26, which is the same as the theoretical value ( 1 + R 4 R 5 ) = 26 match. According to the circuit parameters set in Embodiment 2, a driving voltage with a vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com