Hair styling device

A hairstyle and hair technology, applied in the direction of hair curlers, hairdressing equipment, hair curling or perming devices, etc., can solve the problems of thermal damage of hair, poor sliding, longer hair stay time, etc., and achieve the effect of sticking firmly to each other.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

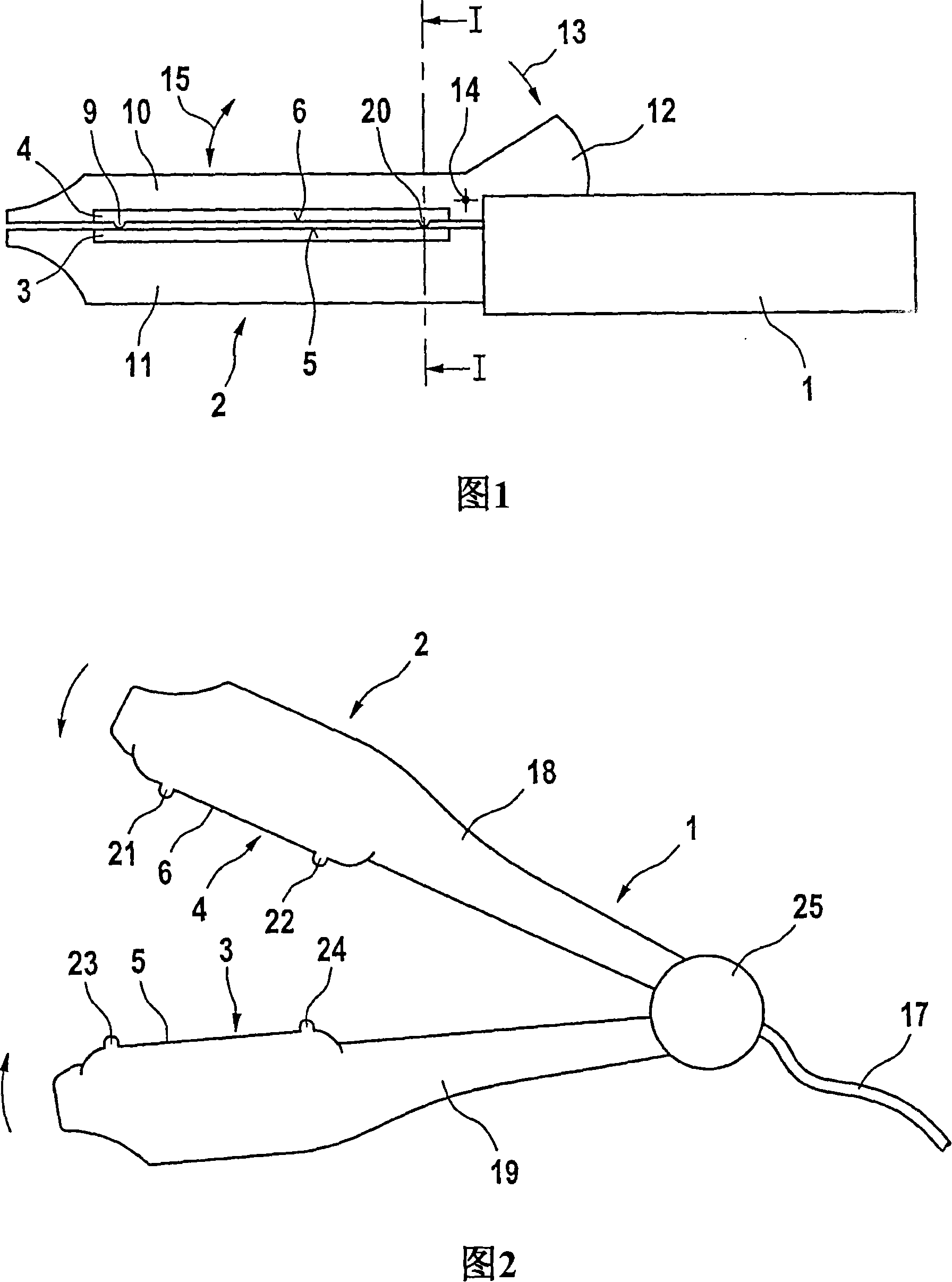

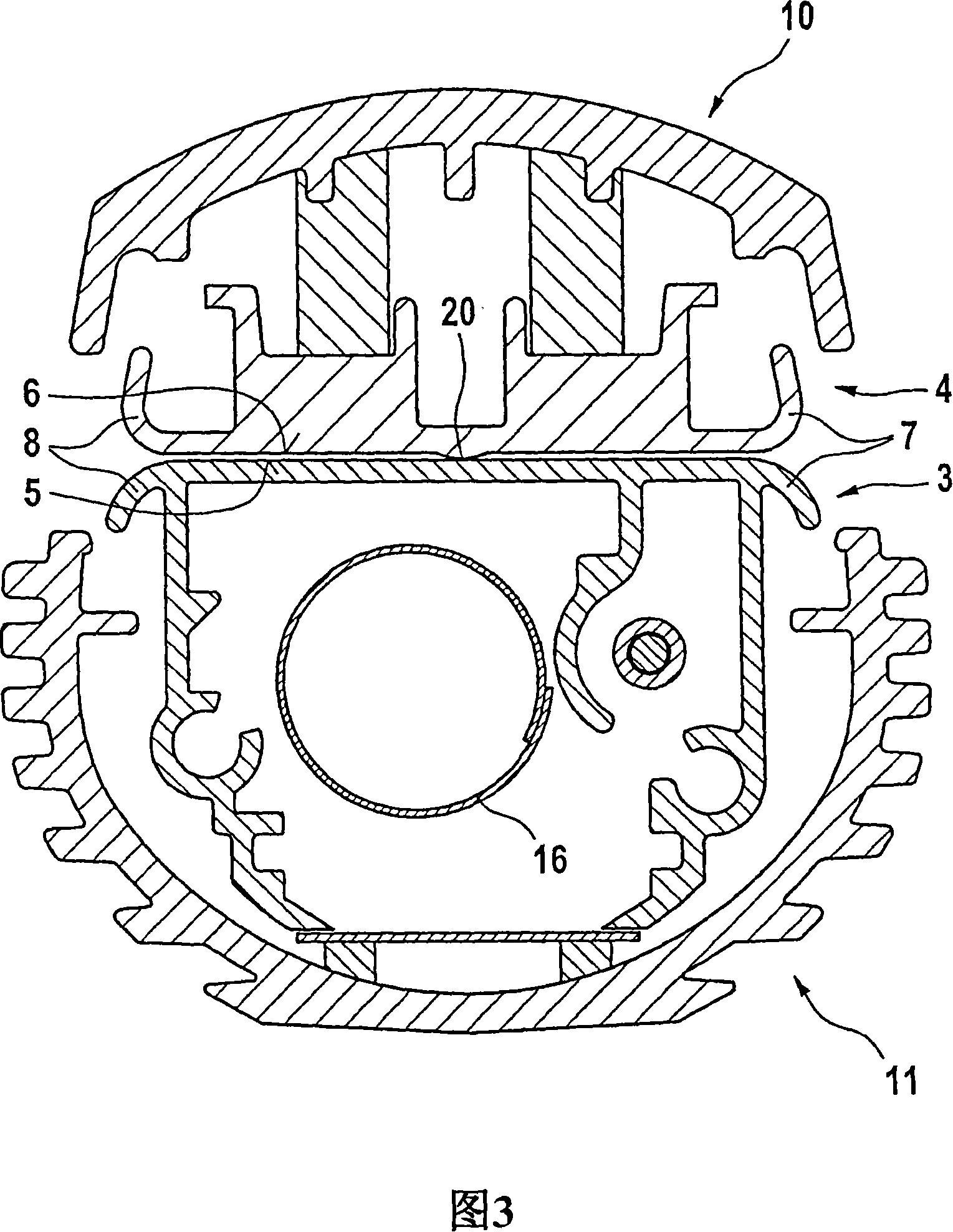

[0025] In FIG. 1 and FIG. 2 , the hair styler has a handle part 1 and a heating part 2 . The heating portion 2 is provided on an extension of the handle portion 1 and can be heated electrically (see FIG. 2 ) or pneumatically (see FIGS. 1 and 3 ). According to FIG. 1, the hairdoser also has a replaceable gas storage device (not shown) in the handle 1 as a source of energy, which provides energy for the catalytic converter 16 (see FIG. 3 ) in the heating part 2. in flameless combustion. According to FIG. 2 , the hairdoser is connected by means of an electrical cable 17 to an electrical network, thereby supplying energy to an electric heating device (not shown) in the heating section 2 .

[0026] In the hair styler shown in FIG. 1 only the heating part 2 has two spring-loaded arms 10 , 11 which can be pressed together like pliers. In this case, the arm 11 remains fixedly connected to the handle 1 . By pressing the operating lever 12 in the direction of the arrow 13 , the secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com