Polylactic acid radical biological degradable material and method for preparing same

A polylactic acid-based, degradable material technology, applied in the field of polylactic acid-based biodegradable materials and their preparation, can solve the problems of inability to obtain high molecular weight polymers with physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

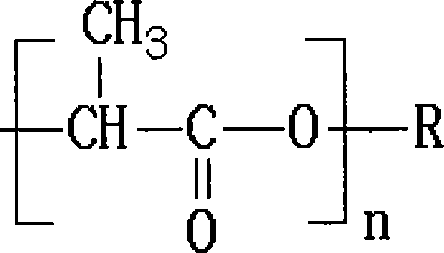

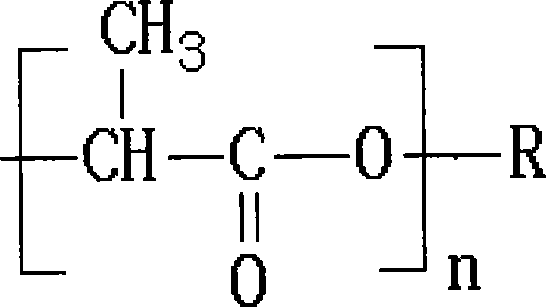

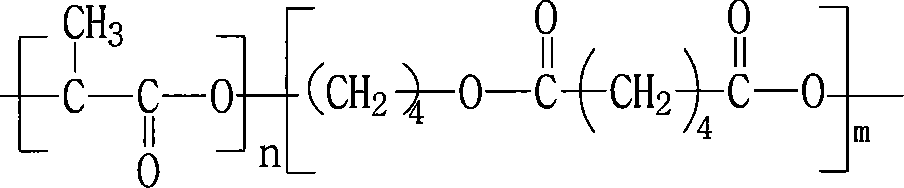

Image

Examples

Embodiment 1

[0031] 30mol of refined L-lactide, 0.3mol of Sn(Oct) 2 , 0.3mol of polybutylene succinate is added in the reactor, vacuumize and ventilate nitrogen repeatedly three times to get rid of the air in the reactor, under the environment of ventilate nitrogen (3L / min), gradually heat up (8 ℃ / 30min) to 160°C for 20 hours. A polymer having a weight average molecular weight of 198,000 was obtained.

[0032]

Embodiment 2

[0034] 30mol of refined D,L-lactide, 0.03mol of SnCl 2 , 0.3mol of polybutylene succinate is added in the reactor, vacuumize, nitrogen gas is repeatedly removed the air in the reactor three times, under the environment of nitrogen gas (3L / min), gradually heat up (10 ℃ / 30min) to 140°C for 20 hours. A polymer having a weight average molecular weight of 215,000 was obtained.

Embodiment 3-7

[0036] 30mol of refined D,L-lactide, 0.03mol of Sn(Oct) 21. A certain amount of polybutylene succinate is added in the reactor, and the air in the reactor is removed by evacuating and passing nitrogen repeatedly three times. Under the environment of passing nitrogen (3L / min), gradually heat up (12°C / 30min) to 160°C for 20 hours.

[0037] polybutylene succinate

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com