Casing tube type gas spray gun

A casing type, gas nozzle technology, applied in the direction of gas fuel burner, combustion method, combustion type, etc., can solve the problems of short residence time, unsatisfactory mixing and convection conditions, incomplete gas combustion, etc., and achieve low cost. , Simple design and appearance, increase the effect of convection and exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

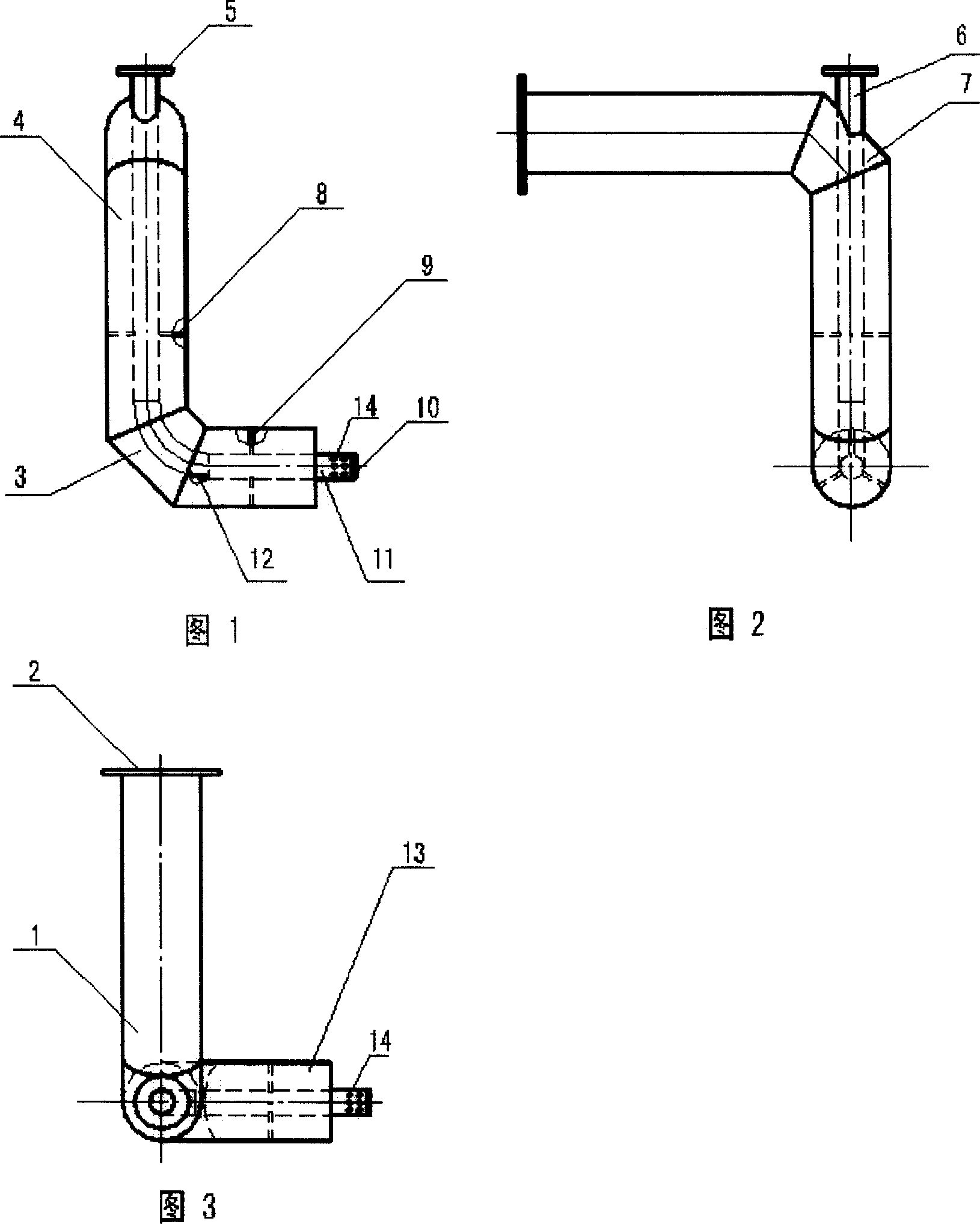

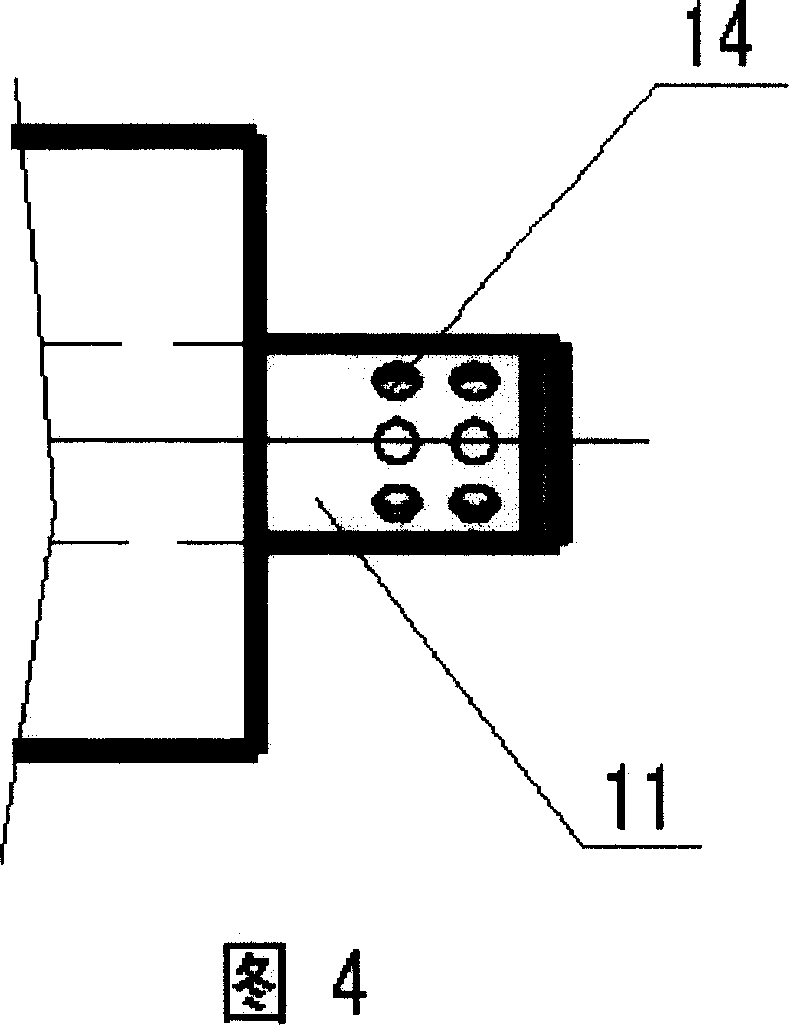

[0025] Embodiment of the present invention: first weld the air inlet pipe 1 with the air inlet pipe connecting flange 2, then weld the air inlet pipe 1 with the air elbow 7 and the air sleeve 4, and the reserved hole of the air elbow 7 is combustible gas The connecting hole for inserting and welding the inlet pipe 6; in addition, the combustible gas inlet pipe connecting flange 5 is welded with the combustible gas inlet pipe 6; the support plate 8 is welded to support the inserted combustible gas inlet pipe 6, and the support plate is divided into three pieces. The 120° angle is welded on the inner wall of the air sleeve 4 and the surface of the combustible gas inlet pipe 6, and then the combustible gas inlet pipe 6 is welded to the combustible gas elbow 12 and the combustible gas nozzle 11, and the combustible gas nozzle 11 is provided with two rings of nozzle holes 14, then weld the air elbow 3 and the air nozzle pipe 13, then weld the fixed plate 9 that supports the combusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com