Hole design of six petal quincuncial hole hot-air stove burning grate

A hole design, plum-blossom hole technology, applied to lighting and heating equipment, air heaters, fluid heaters, etc. The effect of easy to ensure position tolerance, reasonable casting structure and high system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

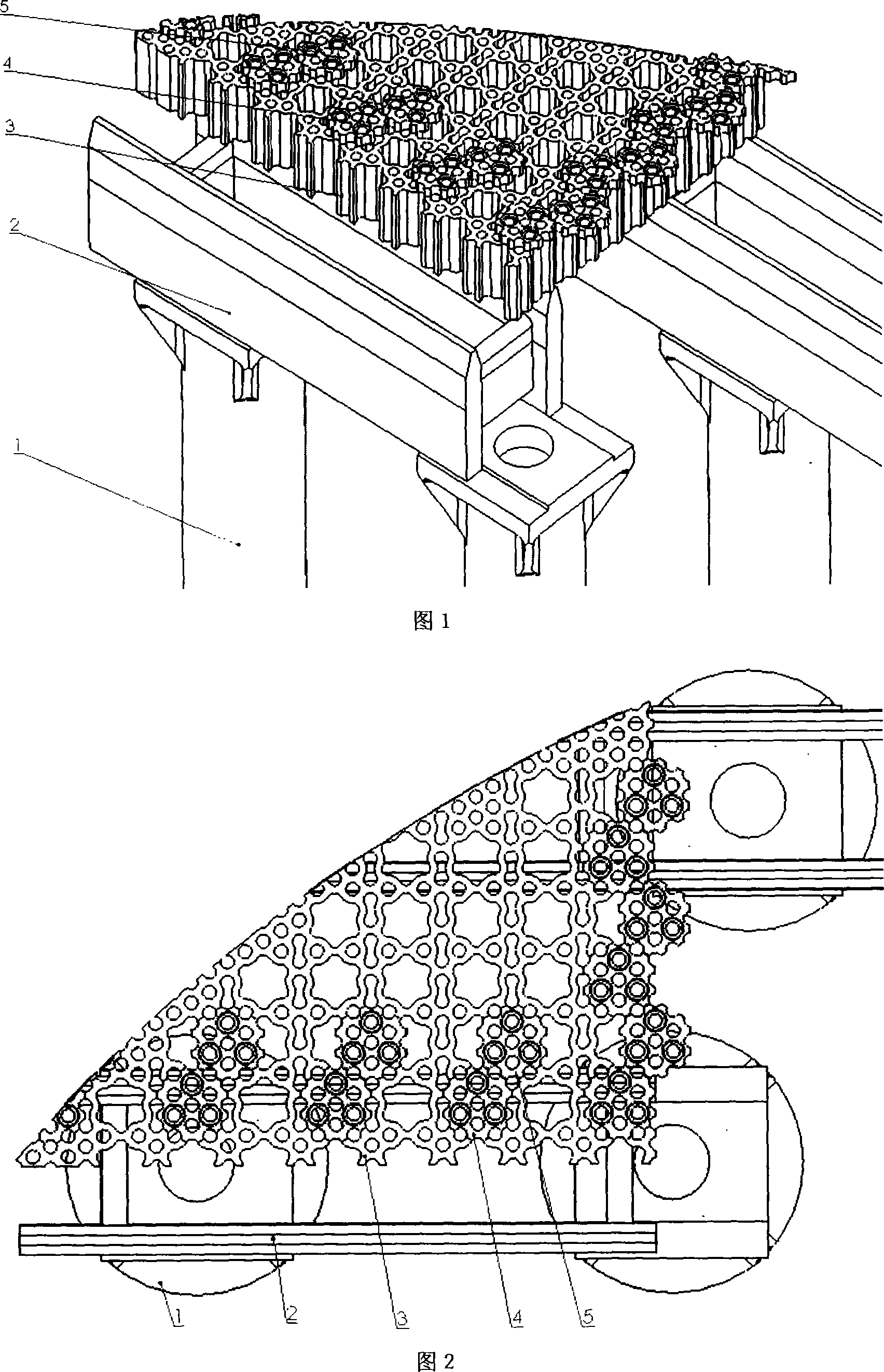

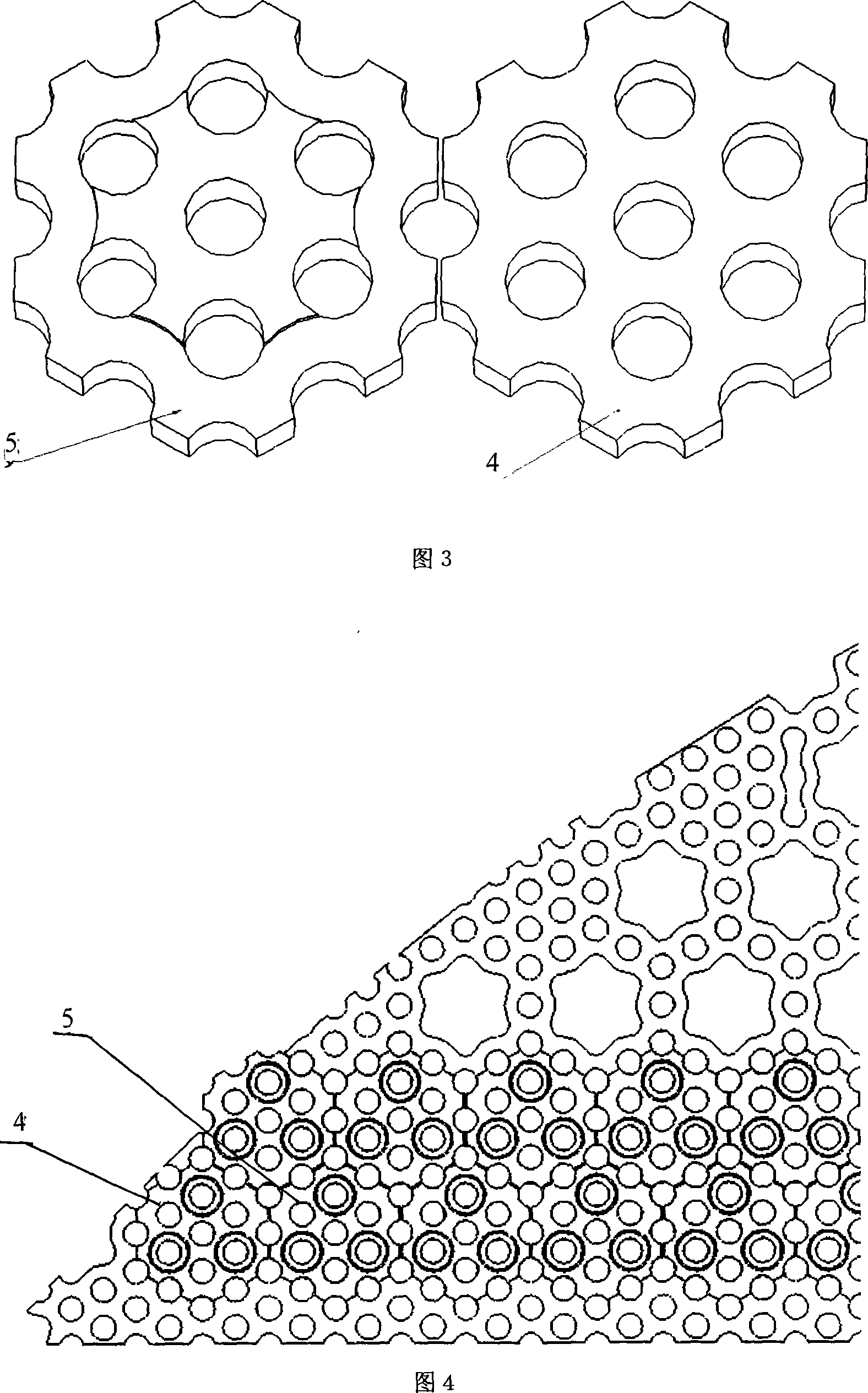

[0026] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0027] As shown in Figure 1, the pass design of the six-petal plum blossom hole furnace grate of the present invention is characterized in that seven densely arranged round holes corresponding to the cast iron lattice block 5 and the lattice brick are arranged on the ironmaking blast furnace hot blast furnace grate Merge into a six-petal plum blossom hole, reduce the cross-section of the contact between the beam 2 and the grate, make the ventilation hole in contact with the beam 2 into a six-petal plum blossom hole or an ∞ hole and pass the six-petal plum blossom hole and the round hole Or ∞-shaped holes or three-petal plum-blossom holes are arranged and combined to form six-petal plum-blossom hole grates of various shapes and sizes. Correspondingly, blast furnace hot blast stoves are designed as checker bricks-six-petal plum-blossom hole f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com