Two-stage centrifugal type cone basket splitter

A centrifugal and separator technology, which is applied to centrifuges and centrifuges with rotating drums, etc., can solve the problems of easily damaged slag and pulp fibers, low working efficiency of separators, power consumption and unenvironmental protection, and achieve vibration Small, reasonable design, effect of lightening workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

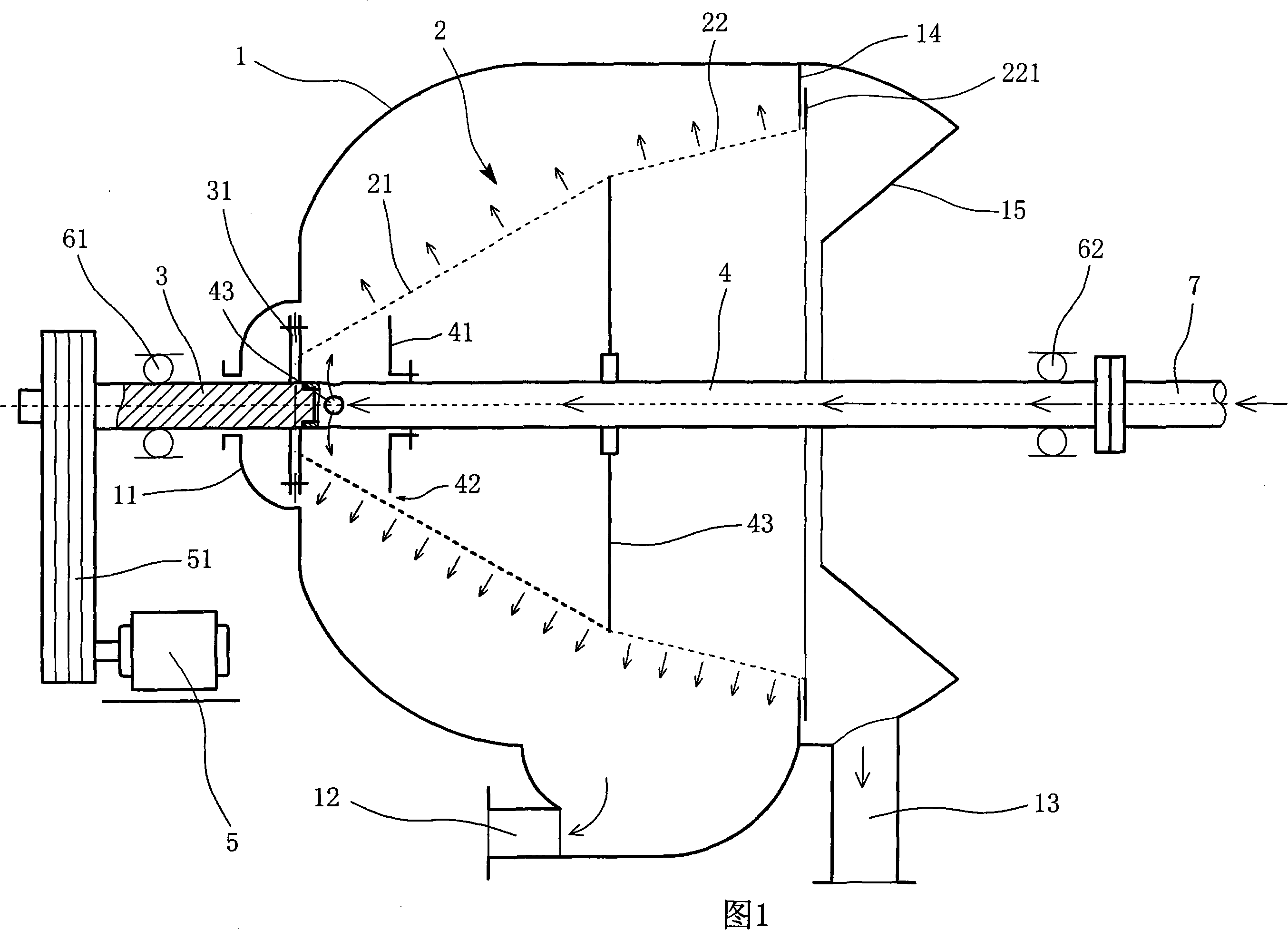

[0015] Refer to Figure 1. The two-stage centrifugal cone basket separator includes a housing 1 fixed on a frame and a screening system, and the frame is not shown in the figure.

[0016] The rear end of the housing 1 is provided with an end cover 11 and an opening at the front end, which is a horizontal hollow cover tube. The bottom of the housing 1 is provided with a juice outlet 12 and a dregs outlet 13 for collecting the separated fruit juice and pomace respectively.

[0017] The screening system includes a cone basket 2, a horizontal transmission shaft 3, a feeding hollow shaft 4, and a motor 5 fixed on the frame, which are installed in the housing 1. The cone basket 2, transmission shaft 3, and feeding hollow shaft 4 are the same Shaft arrangement. The cone basket 2 is arranged in the casing 1, and the cone basket is provided with screen holes; the rear end of the cone basket 2 is small and the front end is large. The cone basket 2 includes a first-stage sieve cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com