Method and system for catelectrode axial force detecting and electrolytic machining of spatium

A technology for processing clearance and axial force, which is applied to electric processing equipment, special circuits for processing, metal processing equipment, etc., and can solve problems such as measuring processing clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

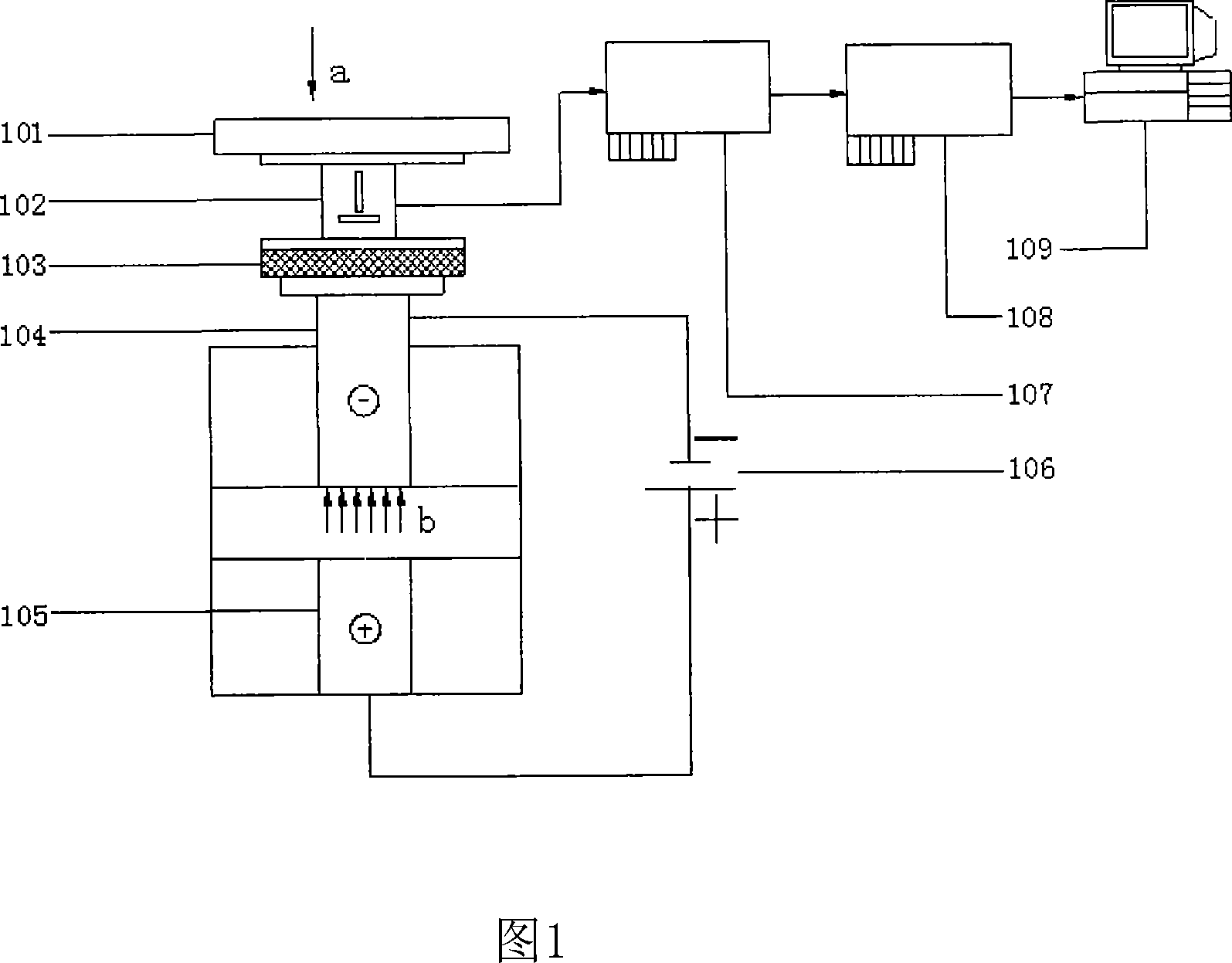

[0017] A method and device for detecting the electrolytic machining gap by cathode axial force of the present invention will be described below in conjunction with the accompanying drawings.

[0018] As shown in Figure 1, the cathode axial force detection method and device for electrolytic machining gap of the present invention include:

[0019] Machine tool spindle 101, the spindle of a general electrolytic machining machine tool, is mainly used to install the electrolytic machining cathode head;

[0020] The axial force sensor 102 detects the force of the electrolyte acting on the cathode head. In this patent, the sensor is embedded between the cathode head and the feed spindle of the machine tool, and the force of the electrolyte acting on the cathode head is transmitted to the shaft. on the force sensor;

[0021] The insulating plate 103 is installed between the sensor and the electrolytic cathode tool, and is used to isolate the small current signal detected by the high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com