Carbonization maintenance aerated concrete

A technology of aerated concrete and carbonation curing, which is applied in the field of building material aerated concrete, which can solve the problems of low strength, long curing time, and low strength, and achieve the effects of low cost, shortened production cycle, and reduced emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Portland cement produced by a cement company in Jinan is selected as raw material, and its chemical composition is: CaO64.81%, SiO 2 21.58%, Fe 2 o 3 3.20%, Al 2 o 3 4.90%, MgO3.70%, SO 3 0.52%.

[0032] Mix the above raw materials with an appropriate amount of water, and add an appropriate amount of gas-generating agent and other additives. After mixing and stirring, pouring and foaming, and resting the embryo body, cut it into 76×38×12mm 3 The bricks are cured with industrial waste gas containing 25% carbon dioxide wt, the curing gas pressure is 1.5bar, and the carbonization curing temperature is 50-100°C. After 5 hours of curing, finished bricks are made.

[0033] After carbonation curing, the weight increase of Portland cement aerated concrete bricks absorbs about 14% of carbon dioxide; its compressive strength is: 6.8MPa.

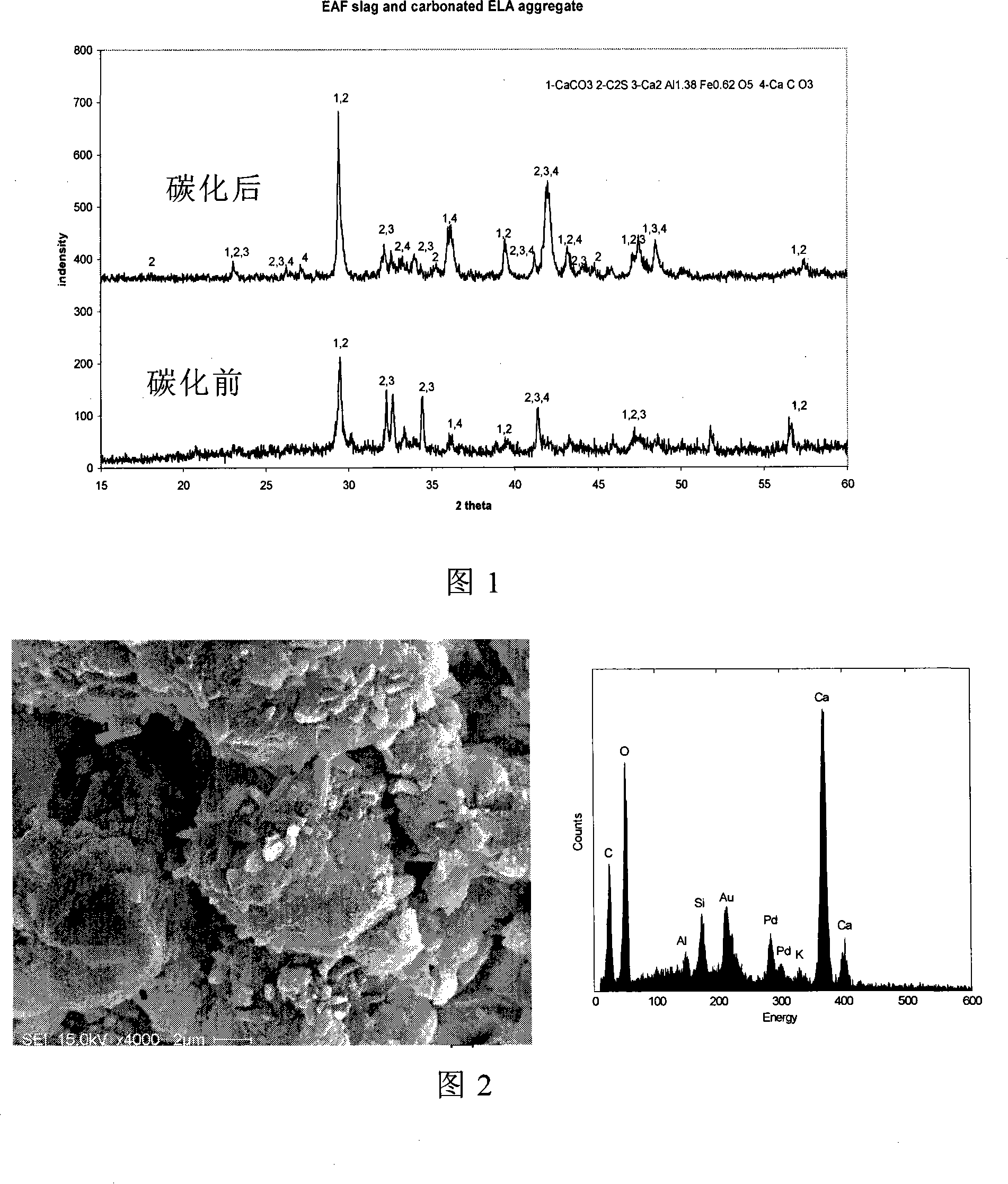

[0034] The SEM-EDS analysis diagram of the Portland cement of the present invention is shown in Figure 2, from which it can be seen that...

Embodiment 2

[0036] The steel slag discharged by Jinan Iron and Steel Group is selected as the raw material, and its chemical composition is: CaO38.91%, SiO 2 13.32%, Fe 2 o 3 23.11%, FeO 21.62%, Al 2 o 3 1.57%, MgO7.61%, P 2 o 5 1.47%, MnO 2 2.29%.

[0037] Add appropriate amount of water to the above raw materials, mix evenly, and add appropriate amount of gas generating agent and other additives, after mixing and stirring, pouring and foaming, and resting embryo body, cut into 76×38×12mm 3 The bricks are cured with industrial waste gas containing more than 25% carbon dioxide wt, the curing gas pressure is 2bar, and the carbonization curing temperature is 50-150°C. After 10 hours of curing, finished bricks are made.

[0038] After carbonization curing, the weight of steel slag increases by absorbing about 13% of carbon dioxide, and its compressive strength is: 7.2MPa.

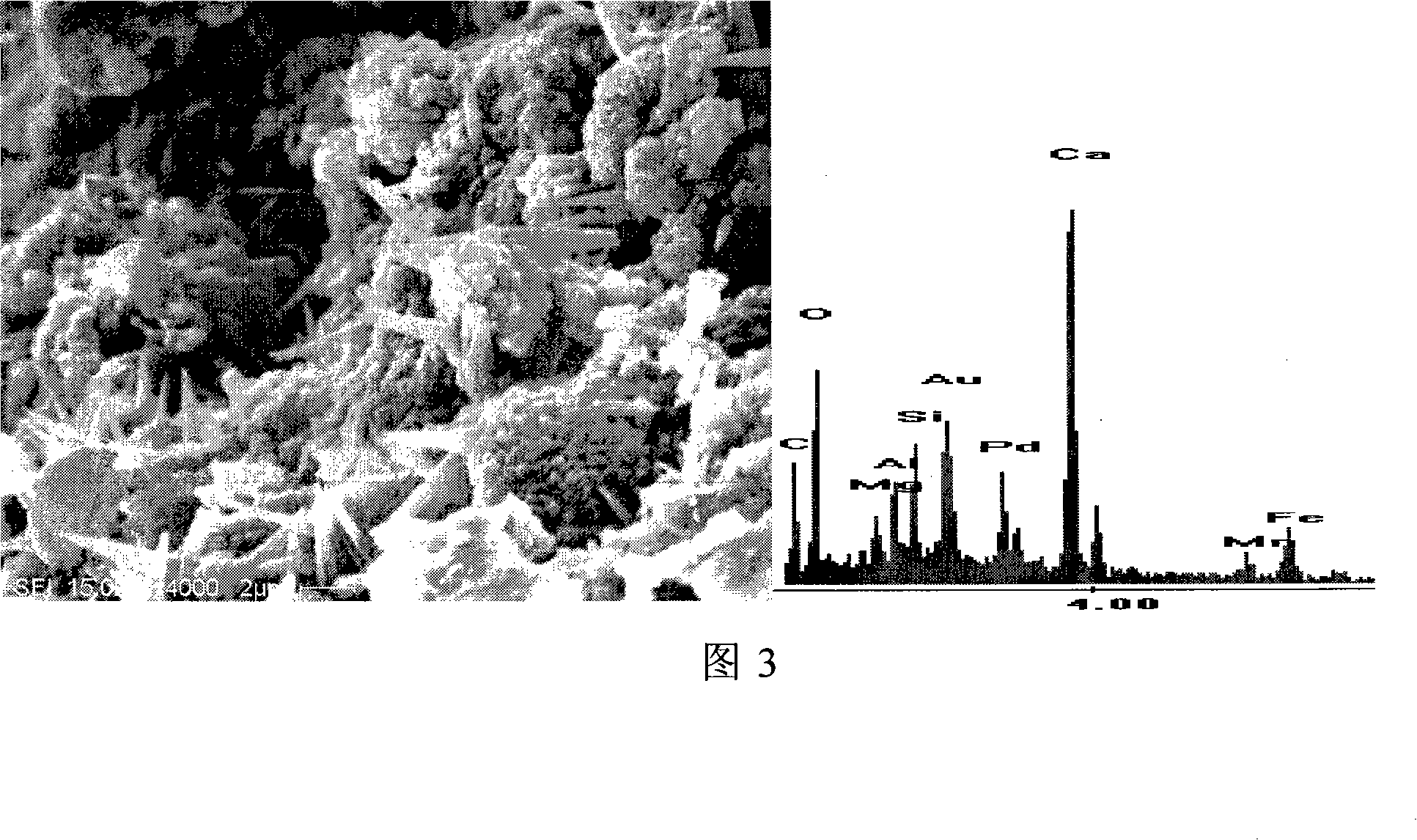

[0039] The XRD analysis diagrams of the above-mentioned carbonized materials before and after carbonization ar...

Embodiment 3

[0042] Choose waste cement as carbonized material, its chemical composition and its weight percentage are:

[0043] CaO

SiO 2

Al 2 o 3

Fe 2 o 3

MgO

Na 2 o

SO 3

LOSS

58.1

14.8

3.9

2.0

2.0

0.85

3.8

13.8

[0044] Mix the above raw materials with air-entraining agent and water evenly, press into air-entrained concrete, cut into 76×38×12mm 3 The bricks are cured with industrial waste gas containing 45% carbon dioxide wt. The curing gas pressure is 5 bar, and the carbonization curing temperature is 50-100°C. After 15 hours of curing, finished bricks are made.

[0045] After carbonization curing, the weight of steel slag increases to absorb about 11% of carbon dioxide, and its compressive strength is: 5.2MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com