Turbine blade erosion tester

A technology of steam turbine blades and experimental devices, applied in the direction of using mechanical devices, measuring devices, testing wear resistance, etc., can solve problems such as not giving a clear quantitative relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

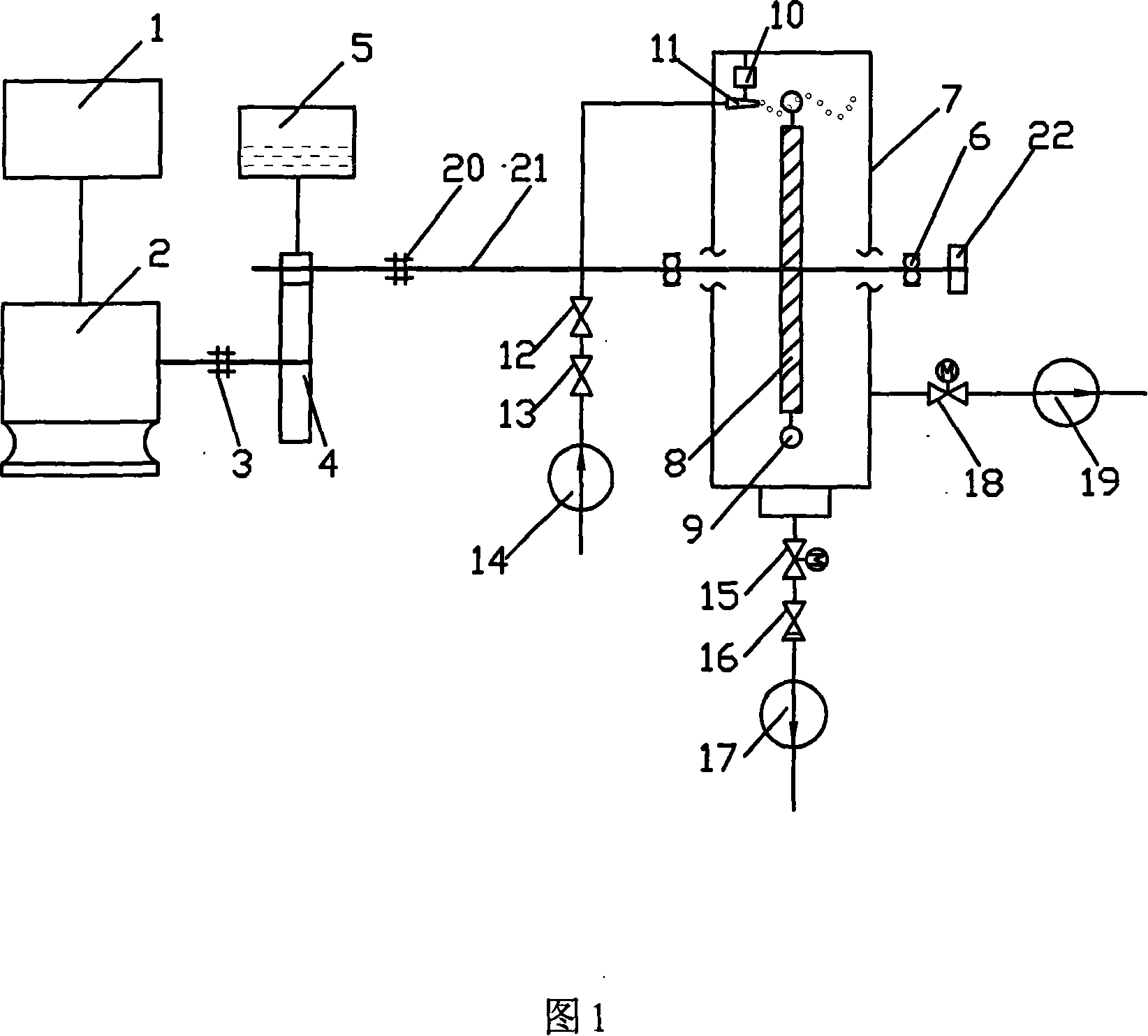

[0009] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0010] Referring to Figure 1, it includes a DC motor control cabinet 1 and a DC motor 2 connected to the DC motor control cabinet 1. The DC motor 2 is used as a prime mover, and the DC motor control cabinet 1 controls the speed, start and stop of the DC motor 2, and the DC motor 2 The output end is connected with the gear speed increaser 4 through the flexible coupling 3, the cooling lubricating oil station 5 is installed on the gear speed increaser 4, and the gear speed increaser 4 drives the rotor 21 to rotate through another flexible coupling 20 , the rotor 21 is supported by two rolling bearings 6, and a closed cylinder 7 is set on the rotor 21. A wheel 8 fixedly connected with the rotor 21 is arranged in the cylinder 7, and a test piece 9 is symmetrically installed on the upper and lower outer edges of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com