Cleaning tool

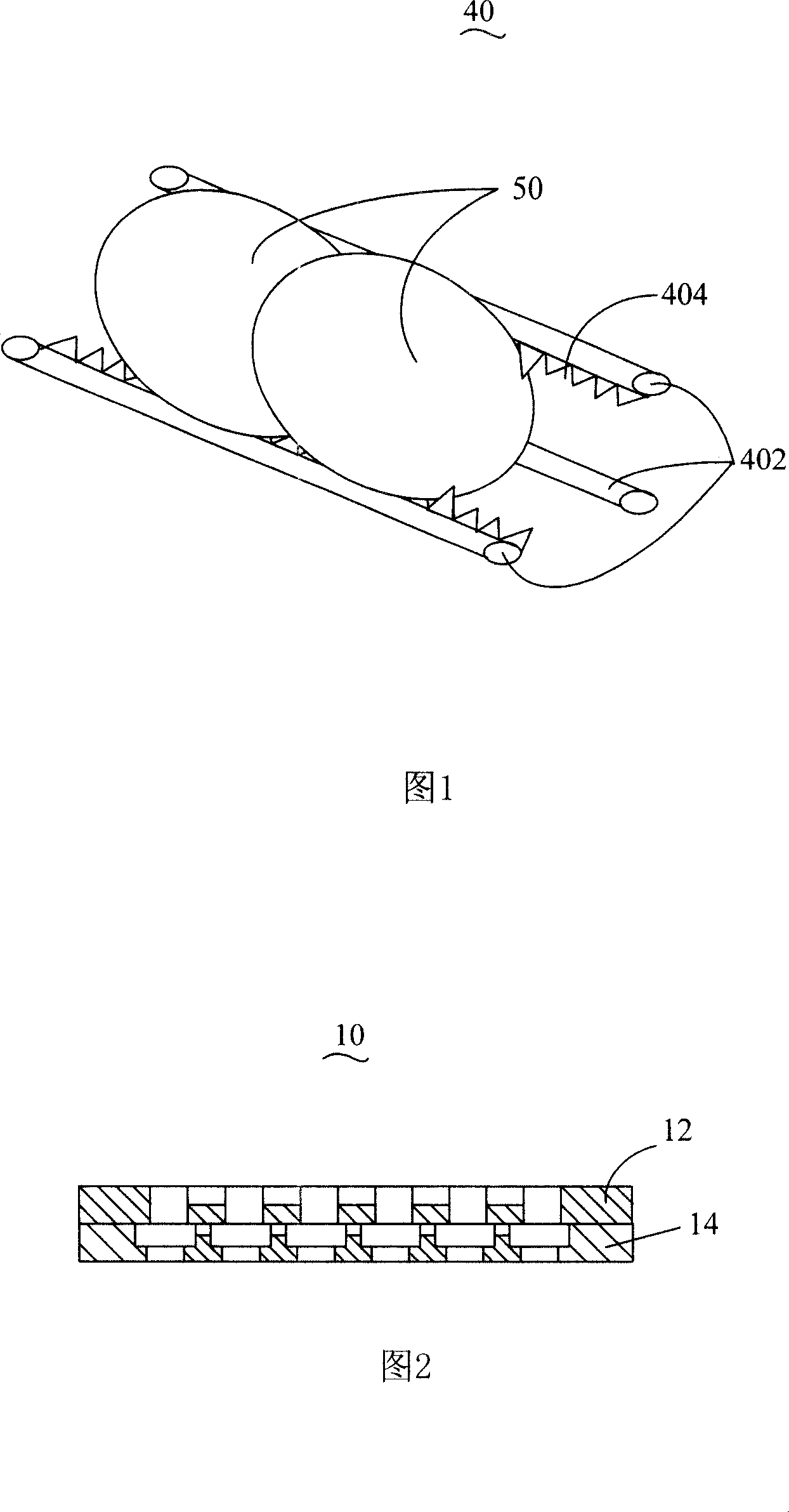

A technology for cleaning jigs and covers, applied to cleaning methods and utensils, manufacturing tools, cleaning flexible items, etc., can solve problems such as difficult to take out, the clamped part of the optical element 50 is not clean, and the optical element 50 is not easy to put in, etc. problems, to achieve the effect of improving efficiency and cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

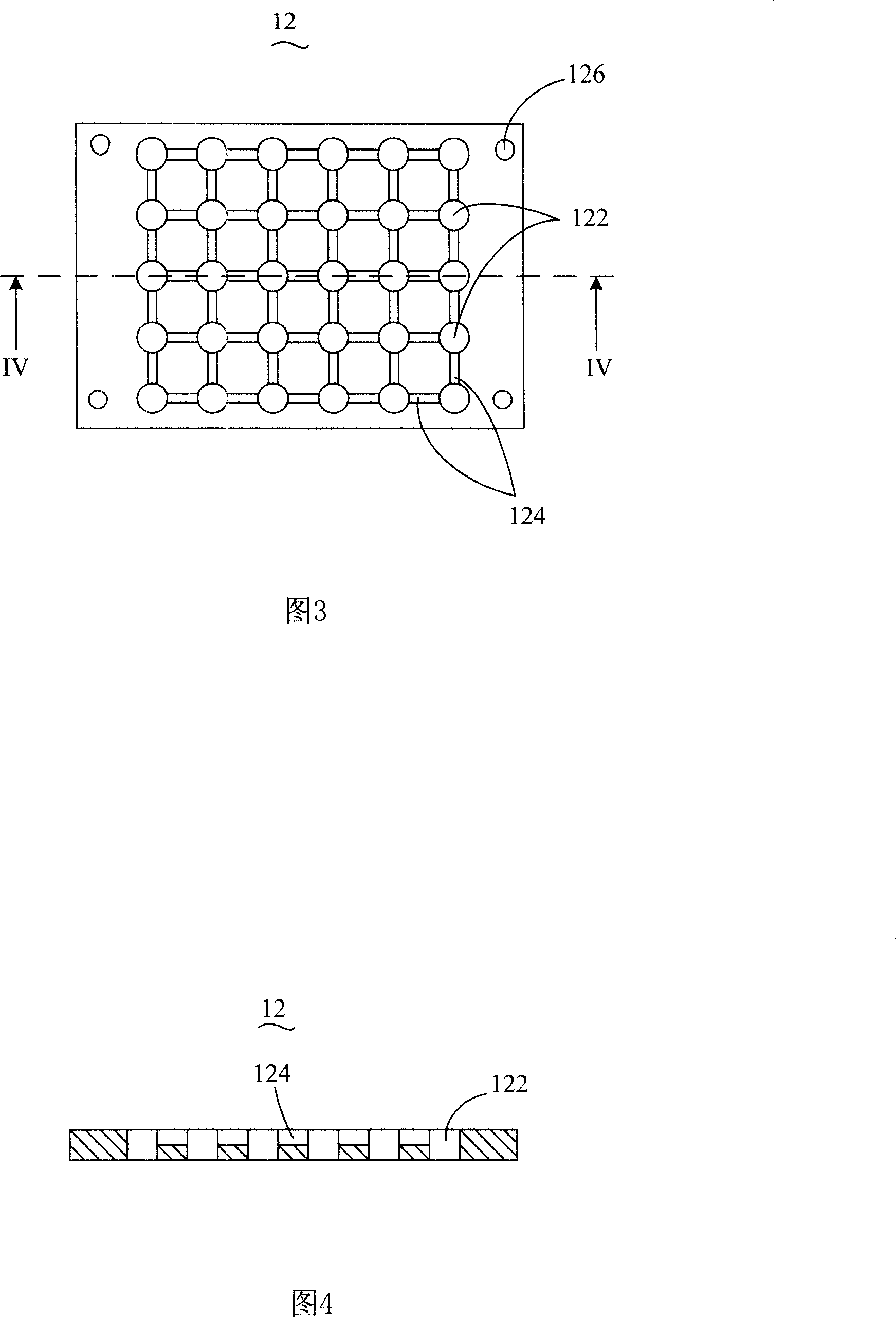

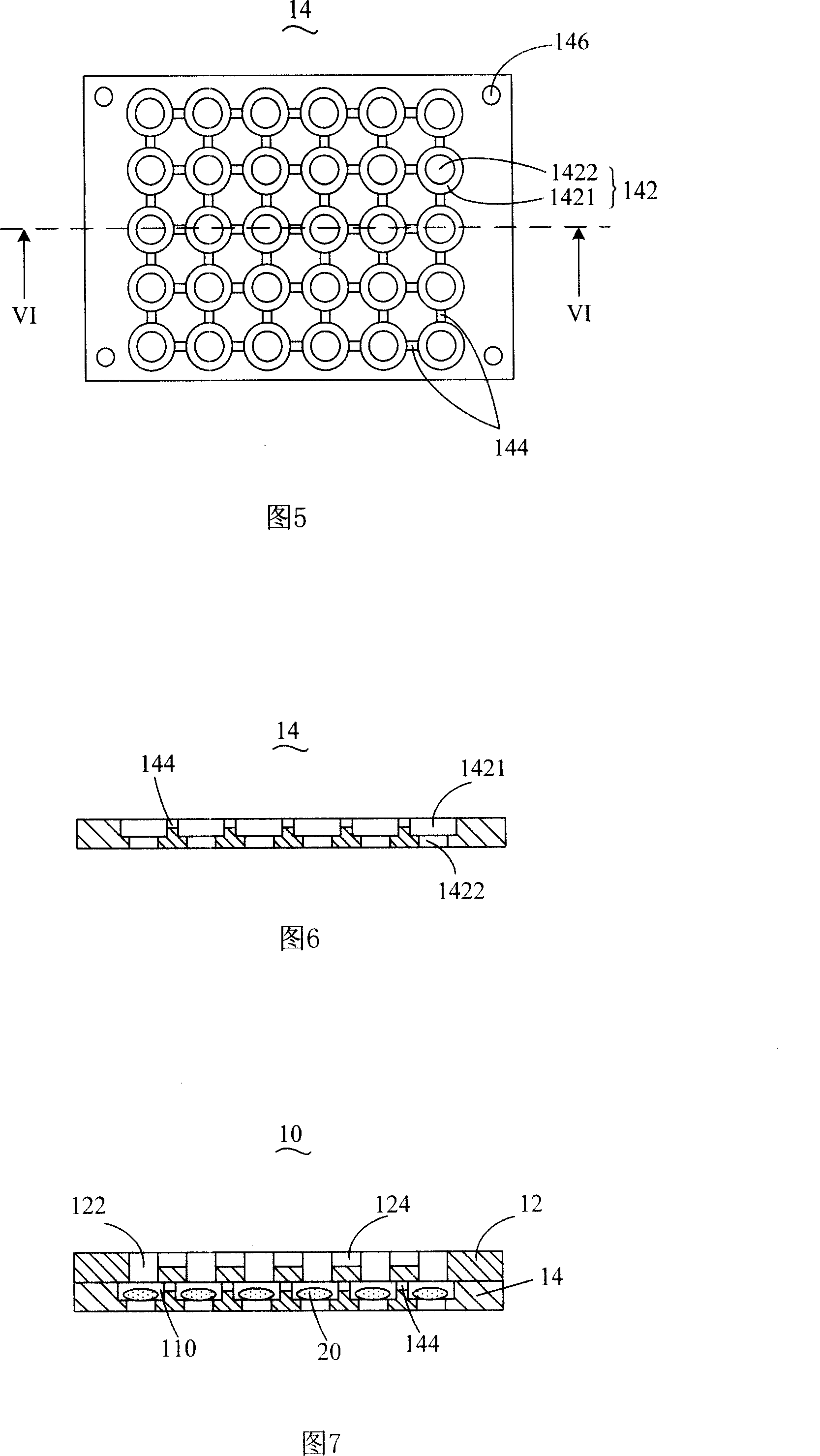

[0016] Referring to FIG. 2 , an embodiment of the present invention provides a jig 10 , the jig 10 includes a cover 12 and a body 14 . The material of the jig 10 is one of aluminum, aluminum alloy, stainless steel, titanium alloy, copper and heat-resistant engineering plastics, and the jig 10 can be manufactured using CNC (Computer Numerical Control) processing technology.

[0017] As shown in FIG. 3 and FIG. 4 , the cover body 12 is provided with a plurality of first through holes 122 and the four corners are respectively provided with first screw holes 126 . The plurality of first through holes 122 are arranged on the cover body 12 in a matrix form with a certain distance therebetween. Optionally, the first through holes 122 are distributed on the cover body 12 in a honeycomb shape.

[0018] In this embodiment, the plurality of first through holes 122 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com