Flame three torches regulating mechanism

A technology of adjusting mechanism and three cutting torches, used in gas flame welding equipment, welding equipment, metal processing equipment, etc., can solve the problem that the shape of the cutting groove cannot be adjusted through the angle, the automatic automatic tracking of the machine is insensitive, and the gap between the worm gear and the worm is difficult to adjust, etc. problems, to achieve the effect of convenient and quick adjustment, sensitive automatic mechanical tracking, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

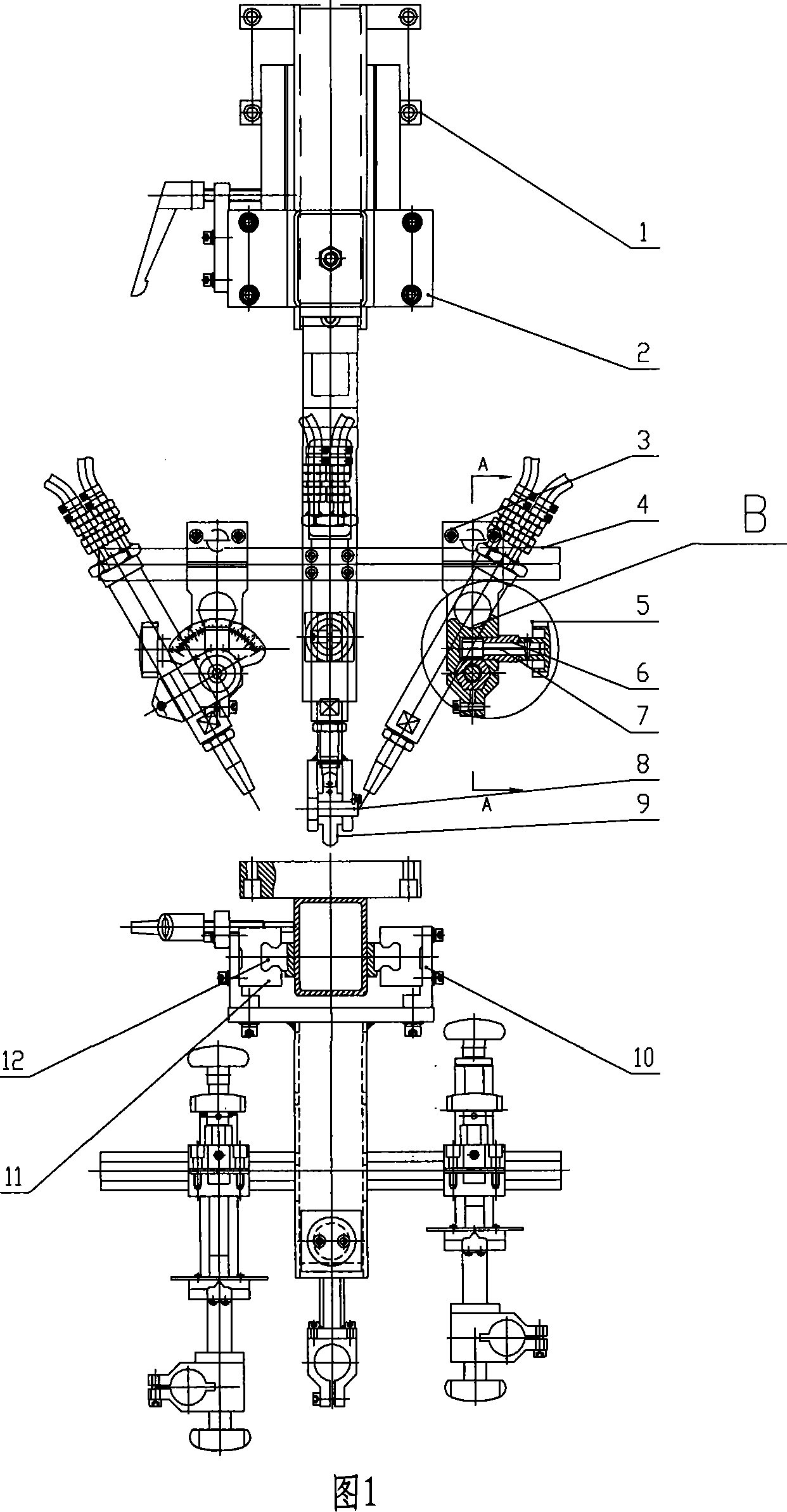

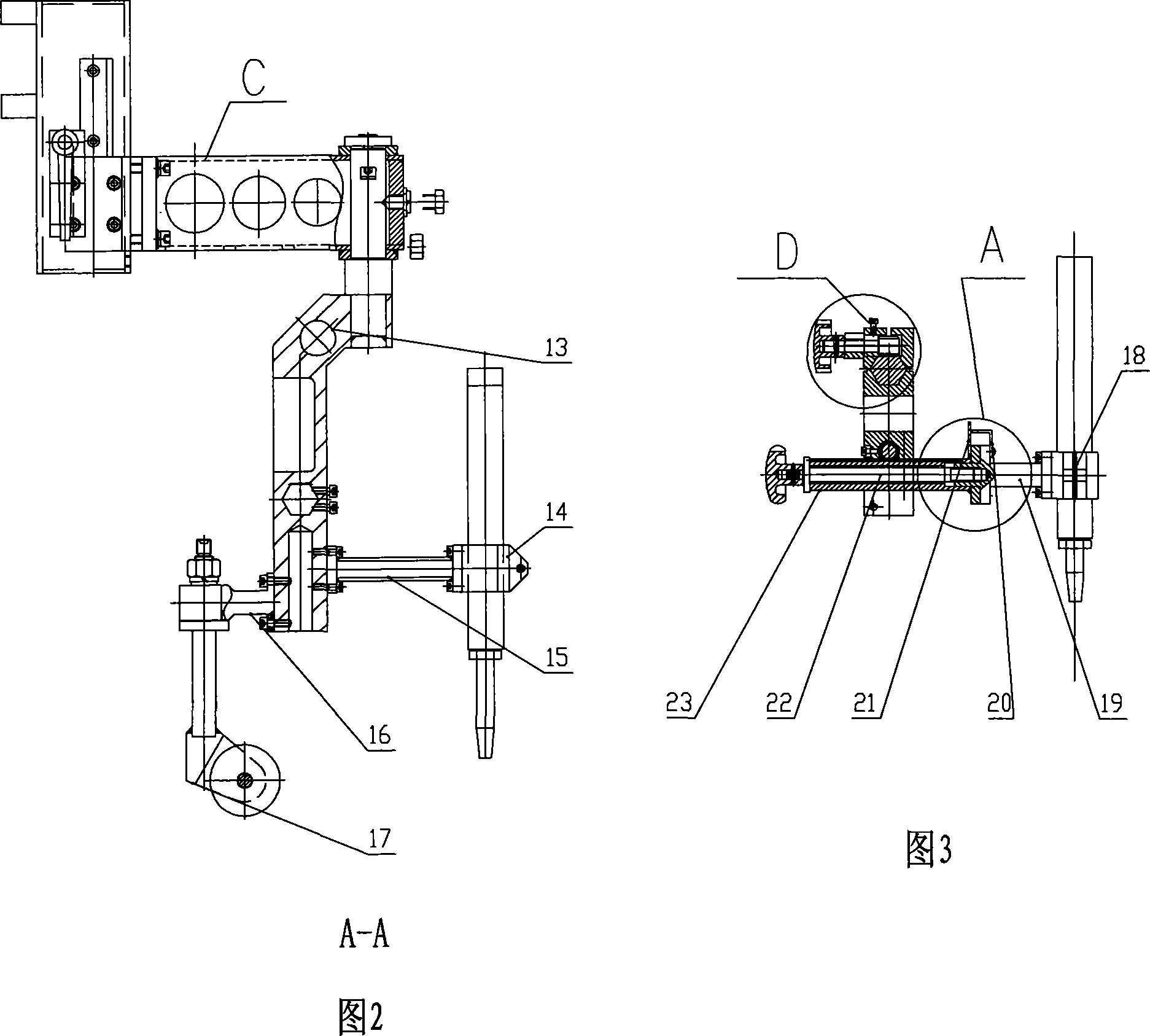

[0015] The present invention mainly consists of connecting frame 1, stretch support 2, fixed block 3, hexagonal rack 4, rotating handwheel 5, gear bearing 6, gear shaft 7, roller shaft 8, roller 9, connecting plate 10, slide block 11, straight line Guide rail 12, bracket 13, holder 14, connecting rod 15, roller connecting frame 16, roller bracket 17, holder 18, connecting rod 19, pointer 20, scale scale 21, locking rod 22, telescopic rod 23, etc. .

[0016] The present invention is mainly composed of the left and right symmetrical two cutting torch angle rotation mechanism A, the front and rear telescopic mechanism B of the cutting torch, the cutting torch lateral movement mechanism D, and the mechanical automatic tracking mechanism C of three cutting torches.

[0017] The left and right symmetrical two cutting torch angle rotation mechanism A is lock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com