Three-section type biomass gasifying furnace

A technology for biomass and gasification furnaces, which is applied in coking ovens, special forms of dry distillation, and the petroleum industry. It can solve problems such as increased purification costs, high tar content in gasification gas, and increased frequency of cleaning cylinders for internal combustion engines to achieve clean and efficient use. , the effect of reducing tar content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

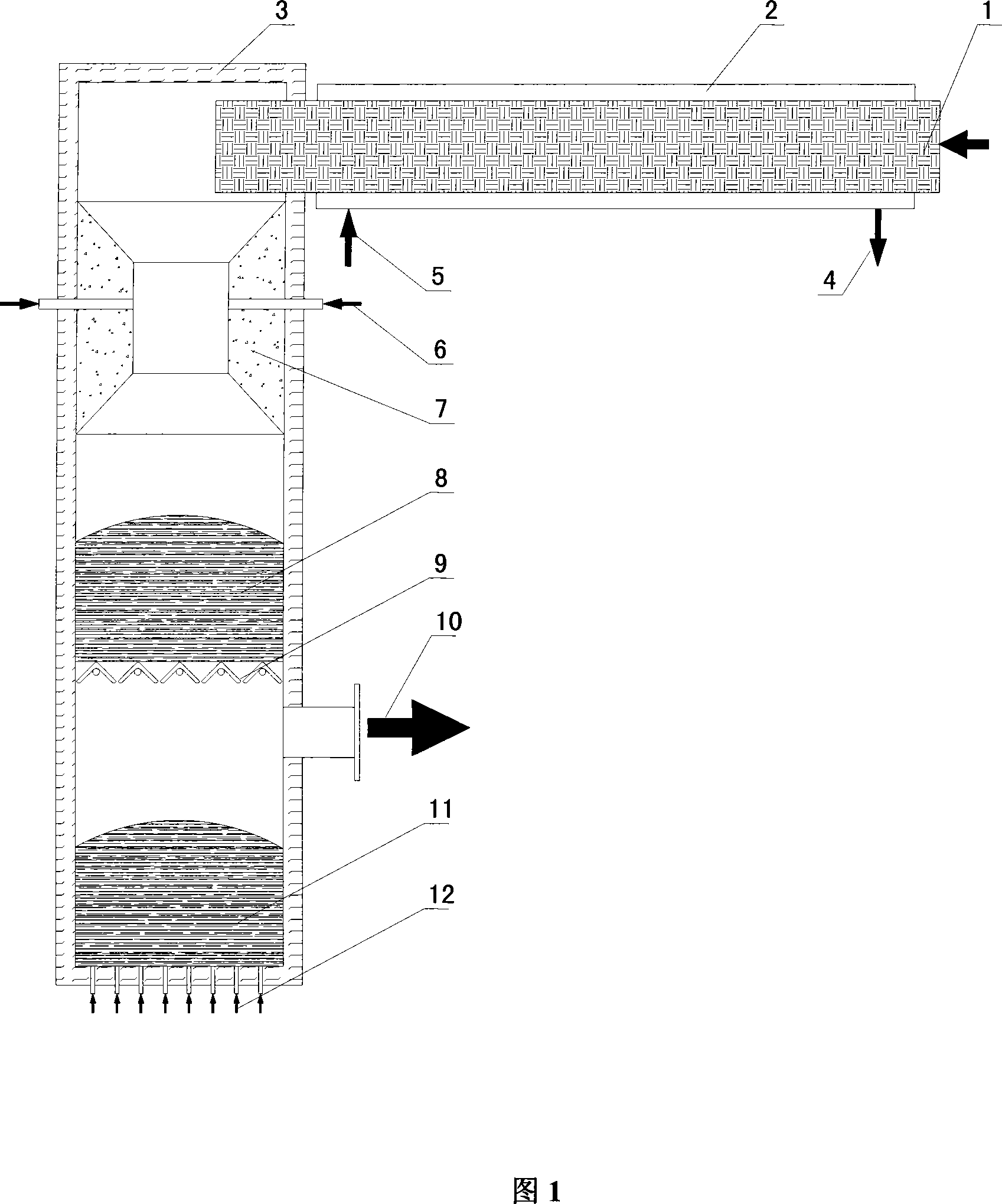

[0015] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0016] The structure of the three-stage biomass gasification furnace of the present invention is as shown in Figure 1. It consists of a furnace body and a pyrolysis cylinder, wherein: the pyrolysis cylinder 2 adopts a jacketed structure, and one end of the pyrolysis cylinder 2 extends into the top of the furnace body. The outer part of the pyrolysis cylinder 2 is welded concentrically by two steel pipes with different diameters. The interlayer between the steel pipes is provided with flue gas and is equipped with a flow-around sheet. The two ends of the steel pipe interlayer are respectively provided with a flue gas outlet 4 and a flue gas inlet. 5.

[0017] The biomass 1 passes through the small-diameter tube inside the pyrolysis cylinder 2, and the diameter of the tube is determined according to the flow rate of the biomass.

[0018] The fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com