Animalcule fuel battery and its method for processing beer waste water

A fuel cell and beer wastewater technology, which is applied in biochemical fuel cells, fuel cells, biological water/sewage treatment, etc., can solve the problems of high cost, high COD, and great influence of temperature on treatment efficiency, achieving low cost and high efficiency , treatment effect and the effect of small production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

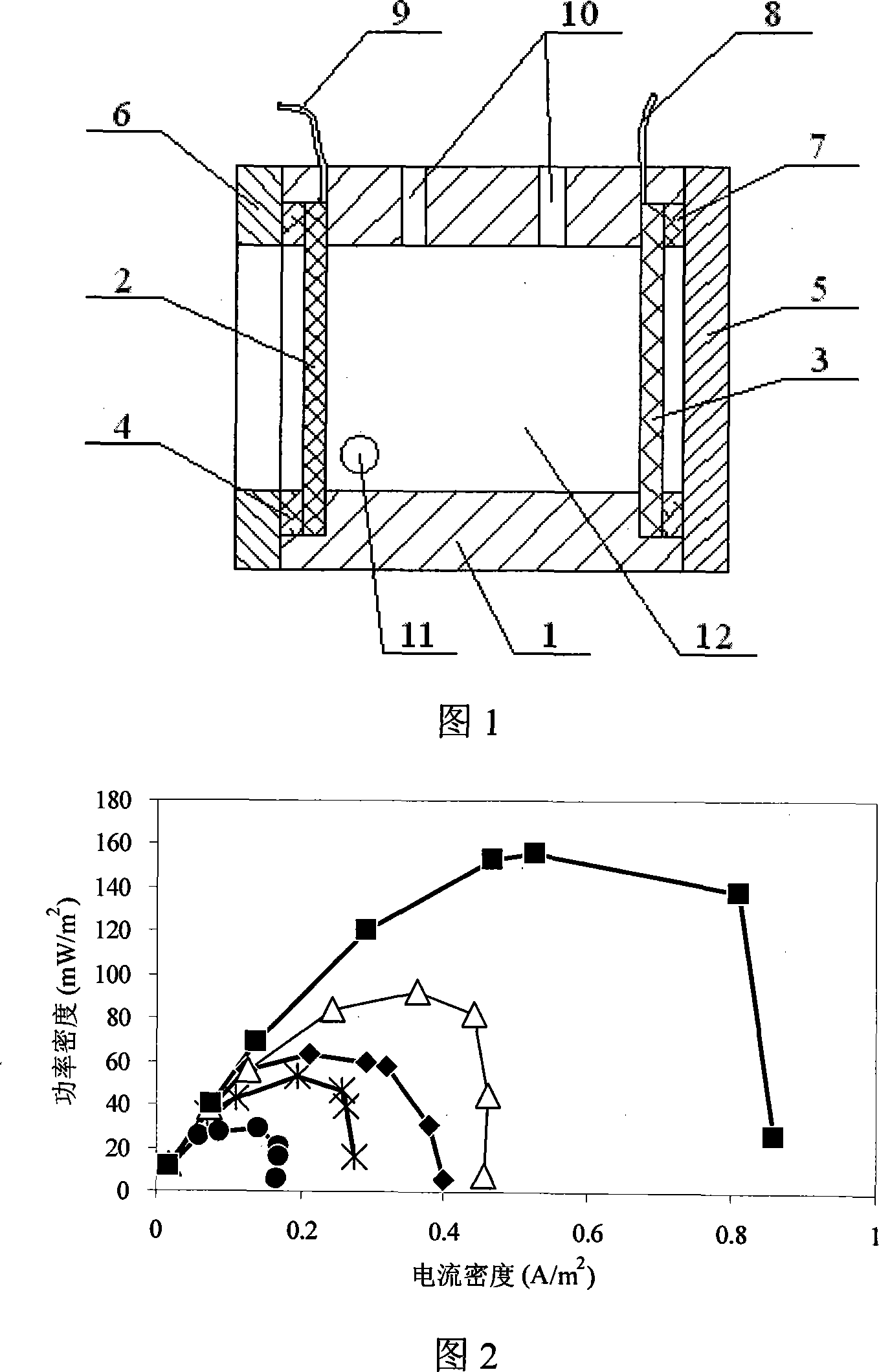

[0013] Specific embodiment one: (see Fig. 1) the microbial fuel cell in the present embodiment is made up of simplified body 1, cathode 2, anode 3, first apron 4, anode cover plate 5, cathode cover plate 6, second apron 7, The anode wire 8 and the cathode wire 9 are composed. One end of the microbial fuel cell is open and the other end is closed; a fuel chamber 12 is formed between the cathode 2, the anode 3 and the cylinder 1, and the distance between the anode 3 and the cathode 2 is not less than 1 cm. There are grooves inside the two ends of the cylinder body 1. The anode 3 and the second rubber ring 7 are installed in the groove at the closed end of the simplified body 1. The port at the closed end of the cylinder body 1 is closed with the anode cover plate 5. The second rubber ring 7 is located between the anode 3 and the The anode cover plate 5 acts as a seal, the groove at the opening end of the cylinder 1 is equipped with the cathode 2 and the first apron 4, the port a...

specific Embodiment approach 2

[0017] Embodiment 2: This embodiment differs from Embodiment 1 in that the thickness of the PTFE waterproof layer is 22-28 μm. Other structures and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0018] Embodiment 3: This embodiment differs from Embodiment 1 in that the thickness of the PTFE waterproof layer is 25 μm. Other structures and connections are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com