Coupling inductance dual-buck full bridge inverter

A technology of full-bridge inverters and coupled inductors, which is applied to electrical components, AC power input conversion to DC power output, and output power conversion devices. It can solve problems such as reducing system reliability and bridge arm switch tubes. Achieve the effect of optimizing design, improving conversion efficiency and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

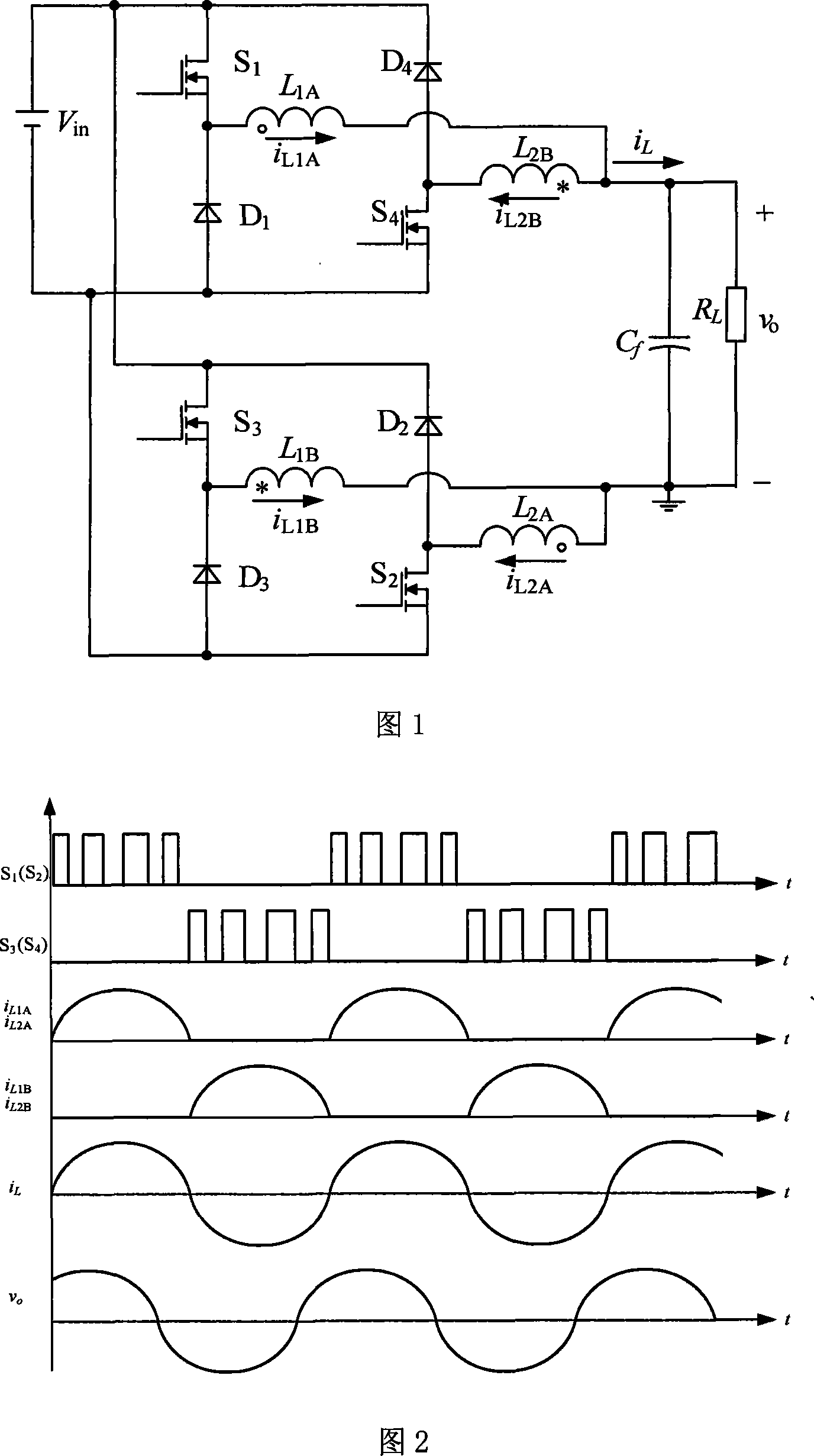

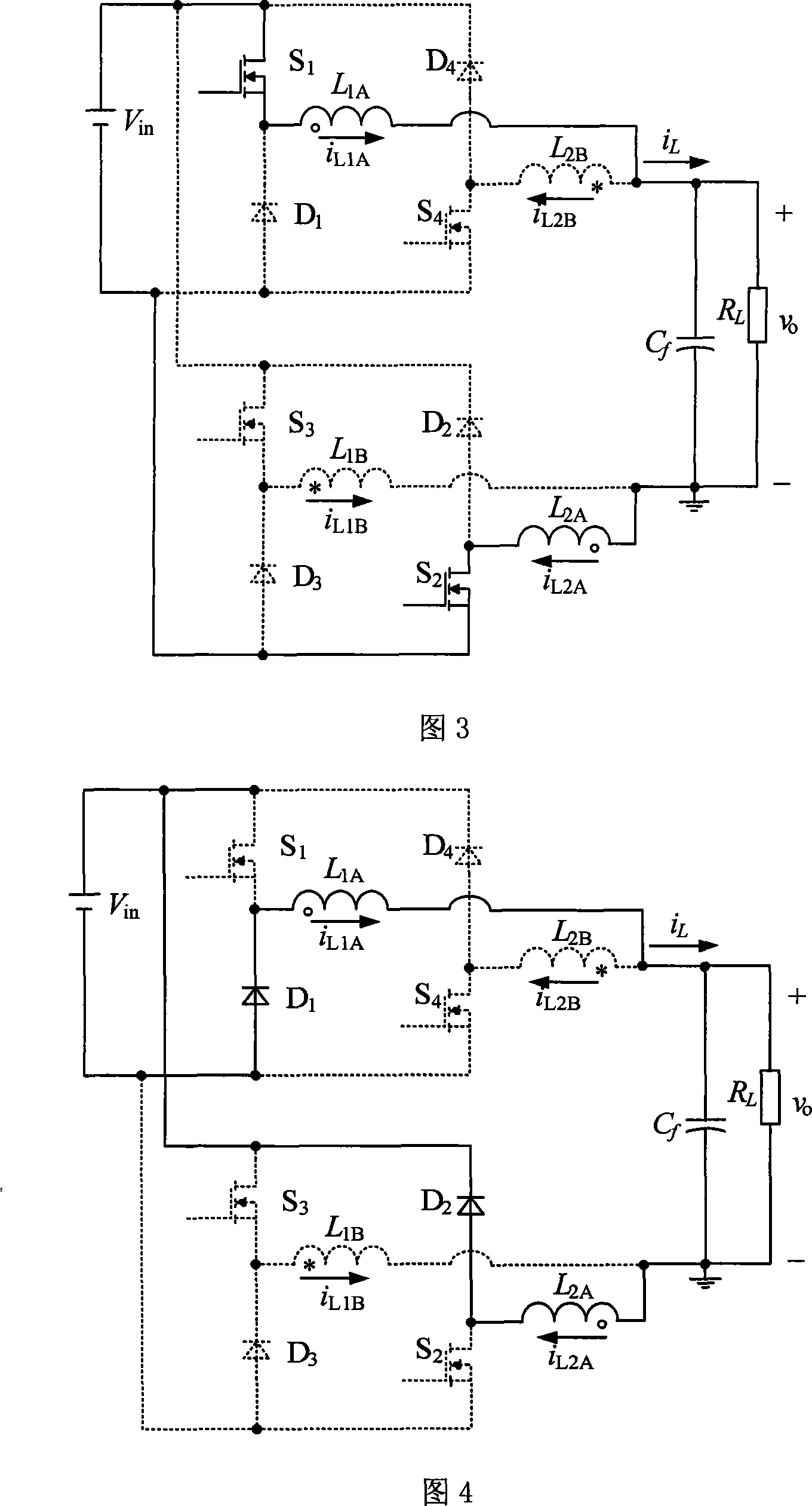

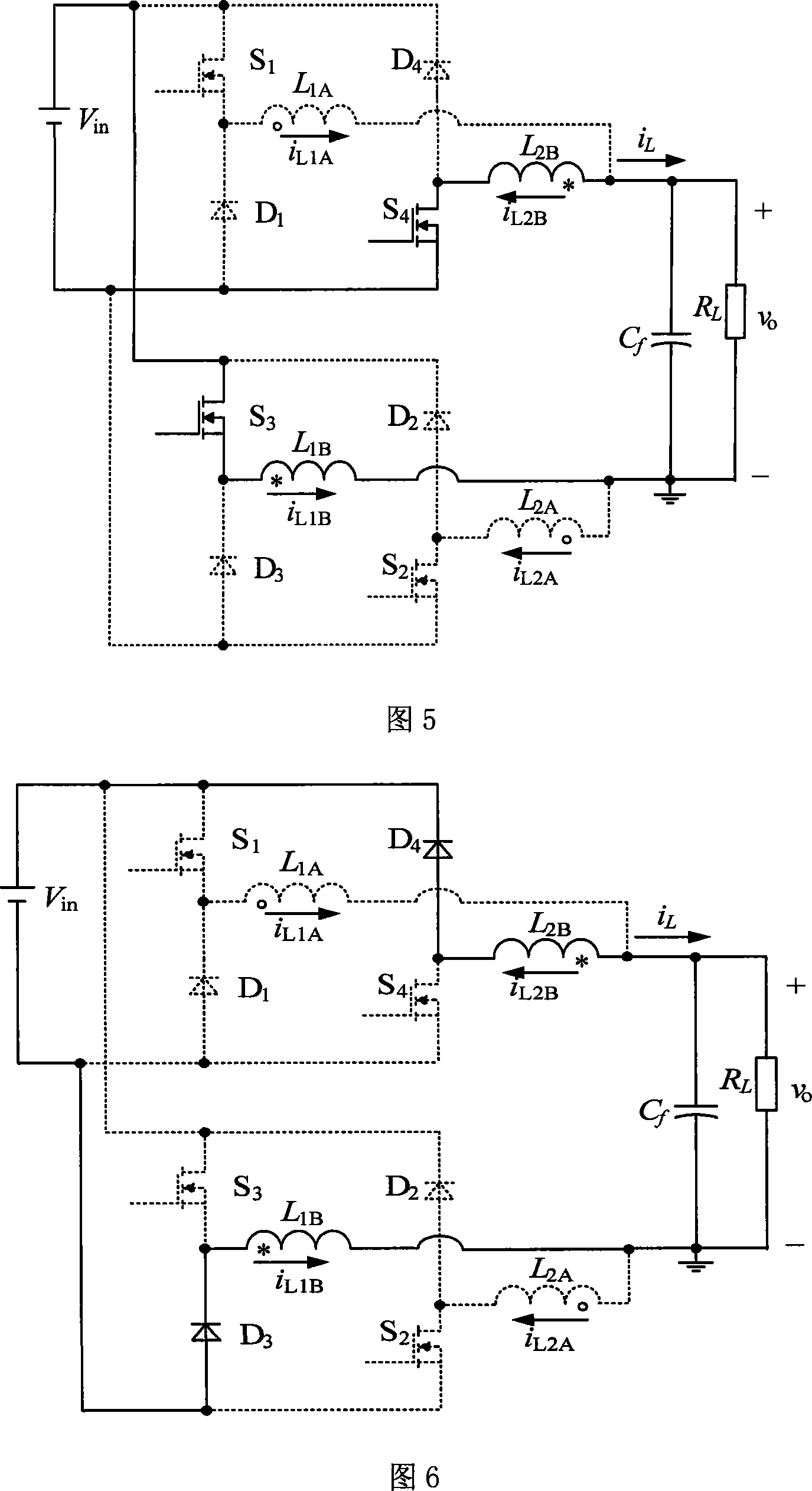

[0011] The specific embodiment of the present invention will be described according to the accompanying drawings. It can be seen from FIG. 1 that the coupled inductor double-step-down full-bridge inverter of the present invention is composed of two step-down circuits. When the sum of the filter capacitor current and the load current is positive (the reference direction is shown in Figure 1), the power supply V in , power switch tube S 1 and S 2 , coupling inductor A, filter capacitor C f and load R L , and the freewheeling diode D 1 and D 2 Form a step-down circuit; when the sum of the filter capacitor current and the load current is negative, the power supply V in , power switch tube S 3 and S 4 , coupling inductor B, filter capacitor C f and load R L , and the freewheeling diode D 3 and D 4 Form another step-down circuit.

[0012] The control method is as follows: define the sum of the output filter capacitor current and the load current as i L , the reference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com