Asphalt macadam stress absorption layer and construction method thereof

A stress-absorbing layer, asphalt gravel technology, applied in the direction of roads, on-site coagulation pavement, roads, etc., can solve the problems of pavement cracking, affecting the service performance and service life of pavement structures, and pavement damage, and achieve extended use. Longevity, ease of mechanization, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

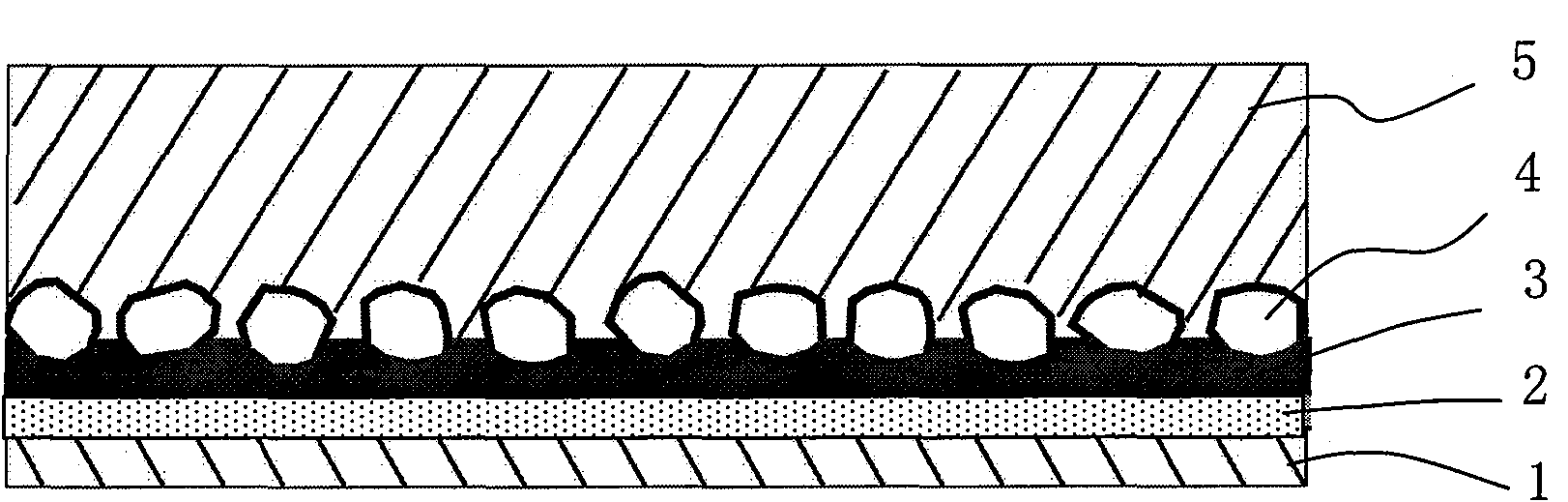

[0024] The following combination figure 1 The construction steps of this embodiment will be described.

[0025] (1) The semi-rigid base layer 1 is lime pulverized coal stabilized crushed stone. Before or after three days of health preservation after the semi-rigid base layer is rolled, use a cleaning machine (car) to roughen the surface of the base layer and blow off the floating ash in time, so that the surface aggregate particles are partially exposed, and there is still a "mirror" phenomenon on the surface of the base layer Use a small milling machine for local milling, roughening and cleaning;

[0026] (2) Use a fully automatic asphalt distributor to spread the connecting layer (permeable layer) material 2: kerosene diluted asphalt (asphalt: kerosene = 60:40), the amount of spraying is 0.5 ~ 0.8kg / m 2 , the spraying temperature is not higher than 70°C;

[0027] (3) When the surface of the permeable layer is slightly dry, use a fully automatic asphalt sprinkler to spread...

Embodiment 2

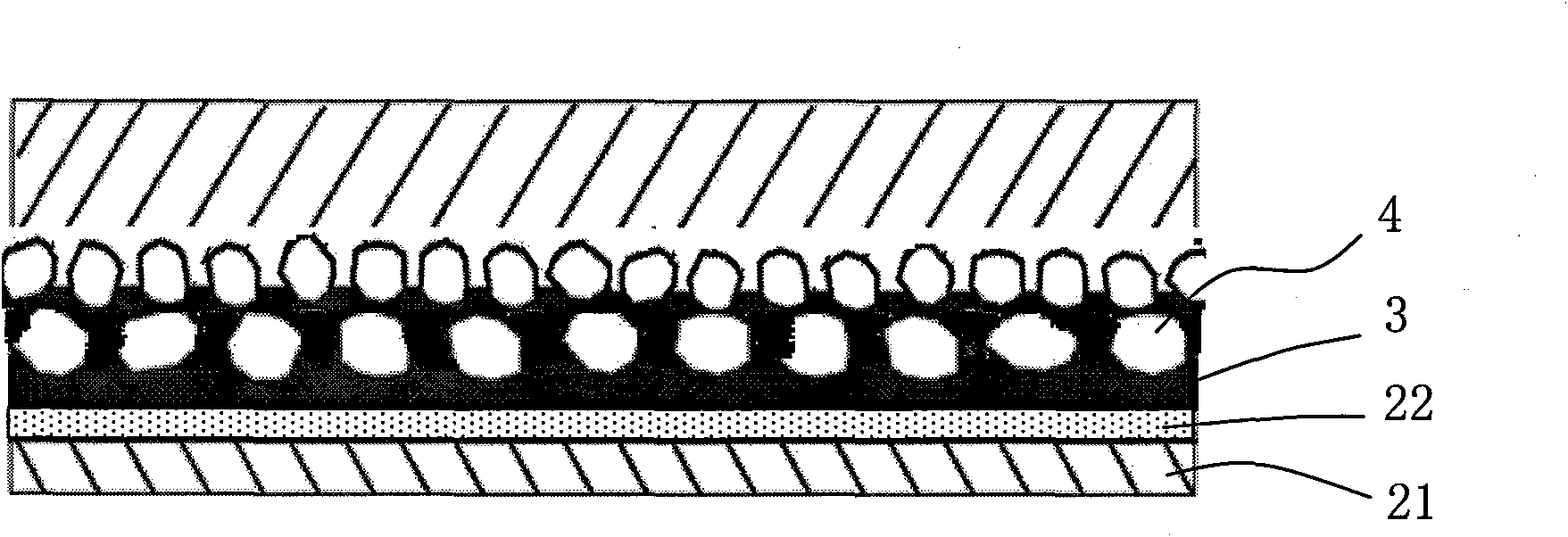

[0032] The construction steps are basically the same as those in Example 1, the difference is that a synchronous gravel sealing vehicle is used to spread stress-absorbing bonding material and gravel at the same time, and the time interval is 3 to 6 seconds; the semi-rigid base is cement-stabilized gravel ; The material of the permeable layer is high-permeability emulsified asphalt, and the spraying amount is 0.4-0.8kg / m 2 , the spraying temperature is 150-170°C; the stress-absorbing binder is high-viscosity emulsified asphalt, and the spraying amount is 0.4-1.0kg / m 2 , spraying temperature 160 ~ 180 ℃;

Embodiment 3

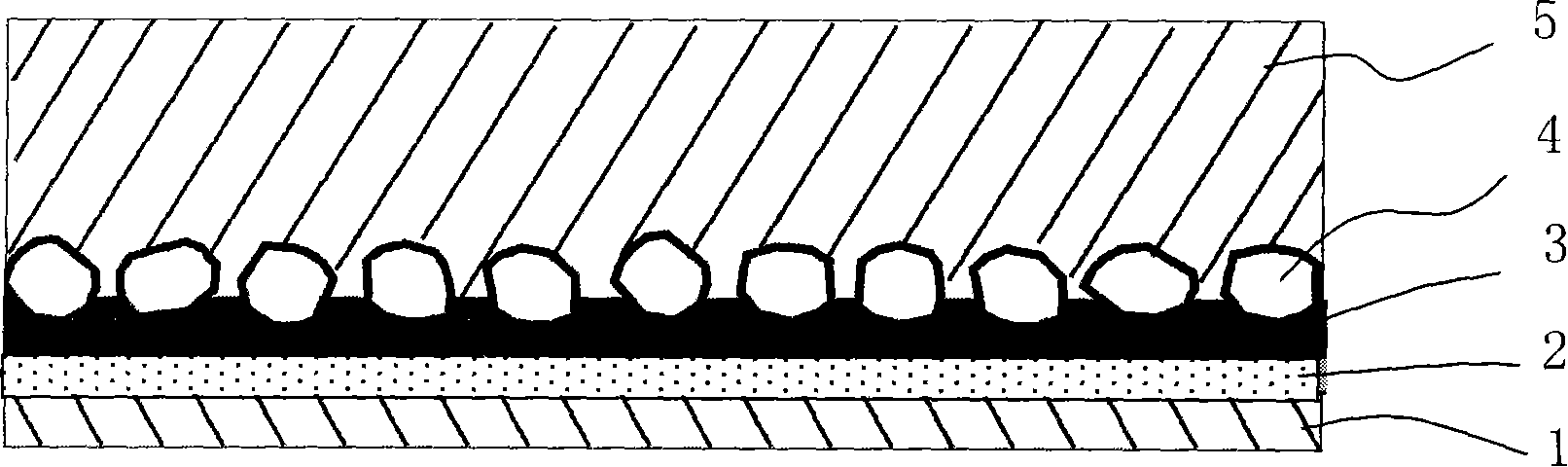

[0034] The base layer of composite pavement is cement concrete pavement.

[0035] (1) Use a milling machine to mill and roughen the concrete pavement, so that the concrete pavement forms a rough, concave-convex surface texture structure, and clean and blow off the floating dust on the surface;

[0036] (2) Smear or sprinkle the connecting layer (interface sticky layer) material: concrete interface binder;

[0037] (3) Use fully automatic asphalt distributors to spread stress-absorbing binders: SBS heat-modified asphalt, and the amount of spraying is 0.8-2.0kg / m 2 , spraying temperature 170 ~ 180 ℃;

[0038] (4) A fully automatic gravel sealing vehicle is used to spread gravel, the size of the gravel is 10-20mm, and the coverage rate is 70-80%;

[0039] (5) Rolling with rubber wheels to make the gravel and asphalt bond well.

[0040] (6) Health preservation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com