Large value piezoelectric quartz multi-component force sensor

A technology of force sensor and piezoelectric quartz, which is applied in the field of six-dimensional force value measurement, can solve the problems that cannot meet the requirements of six-dimensional force measurement of force value, and achieve the effect of simple structure, high sensitivity and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

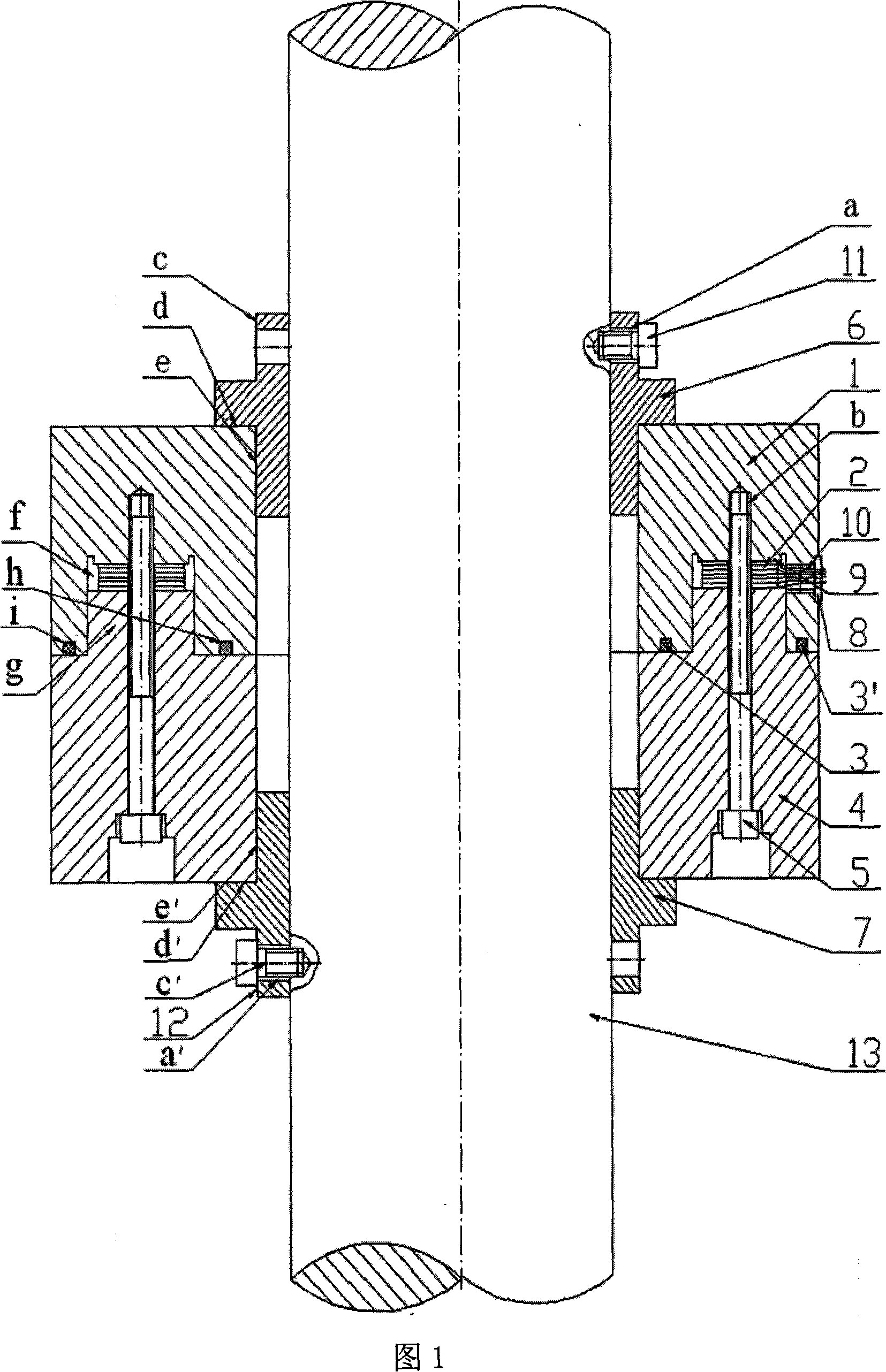

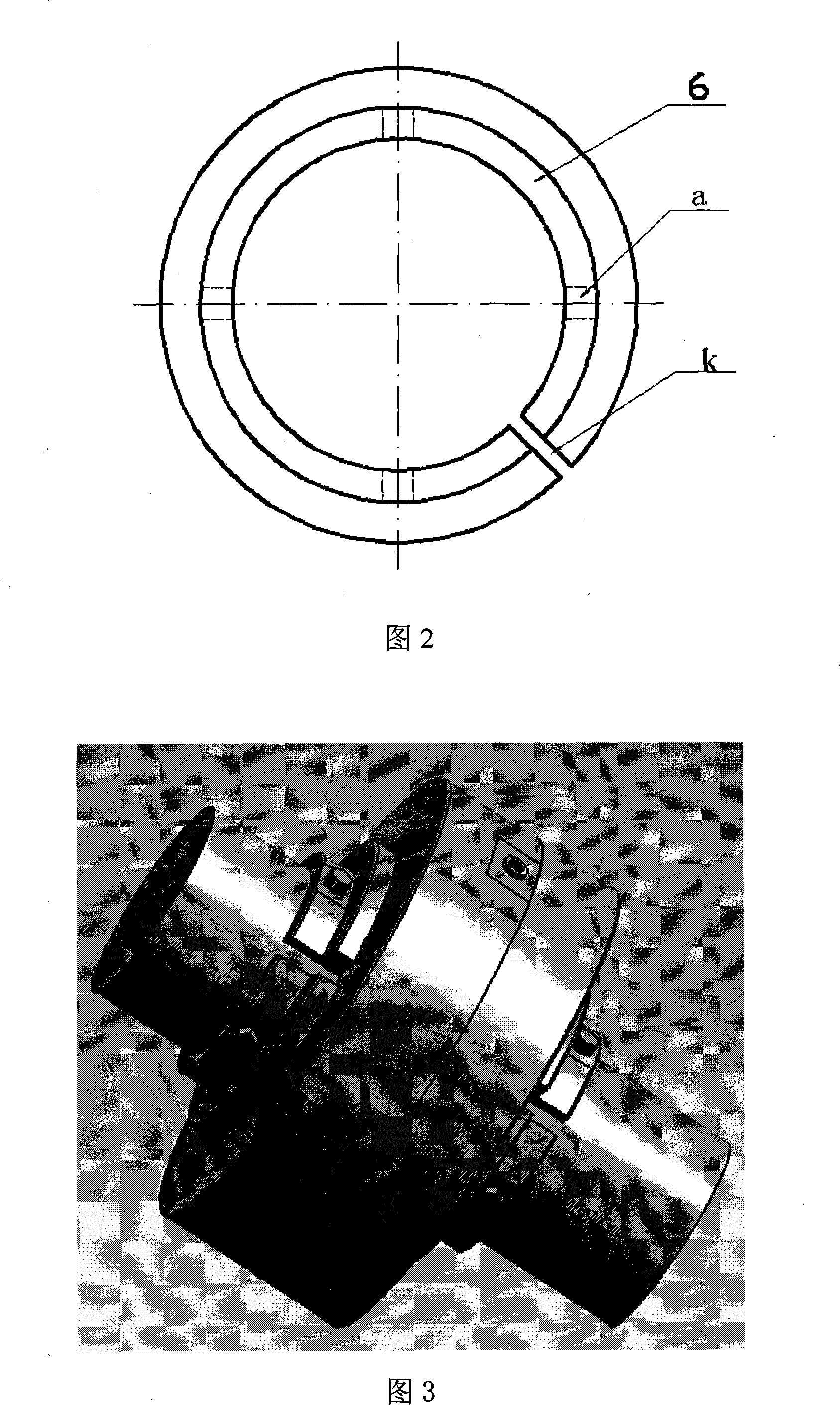

[0009] The implementation of the present invention will be described in detail in conjunction with the accompanying drawings. As shown in FIG. 1 , the material of the sensor body is stainless steel, and the material of the upper opening sleeve 6 and the lower opening sleeve 7 is alloy steel. The geometric parameters of the elastic link should be selected to ensure that the stiffness of each phase is the same. When in use, the lower open sleeve 7 is first installed on the intermediate shaft 13, fastened with bolts 12, then the sensor body is placed on the intermediate shaft 13, the sensor body is fastened by the elastic force of the lower open sleeve 7, and then The upper opening sleeve 6 is sleeved on the intermediate shaft 13 , the sensor body is fastened by elastic force, and then the upper opening sleeve 6 is fixed on the intermediate shaft 13 with bolts 11 . When the shaft is stressed, the upper open sleeve 6 and the lower open sleeve 7 act on the sensor body, and act on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com