Polymer pressure-specific volume-temperature relation indirect test method and its device

A test method and test device technology, which is applied in the indirect test of temperature relationship, polymer pressure, and specific volume, and can solve the problems of mercury in the test medium, which is poisonous and volatile.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

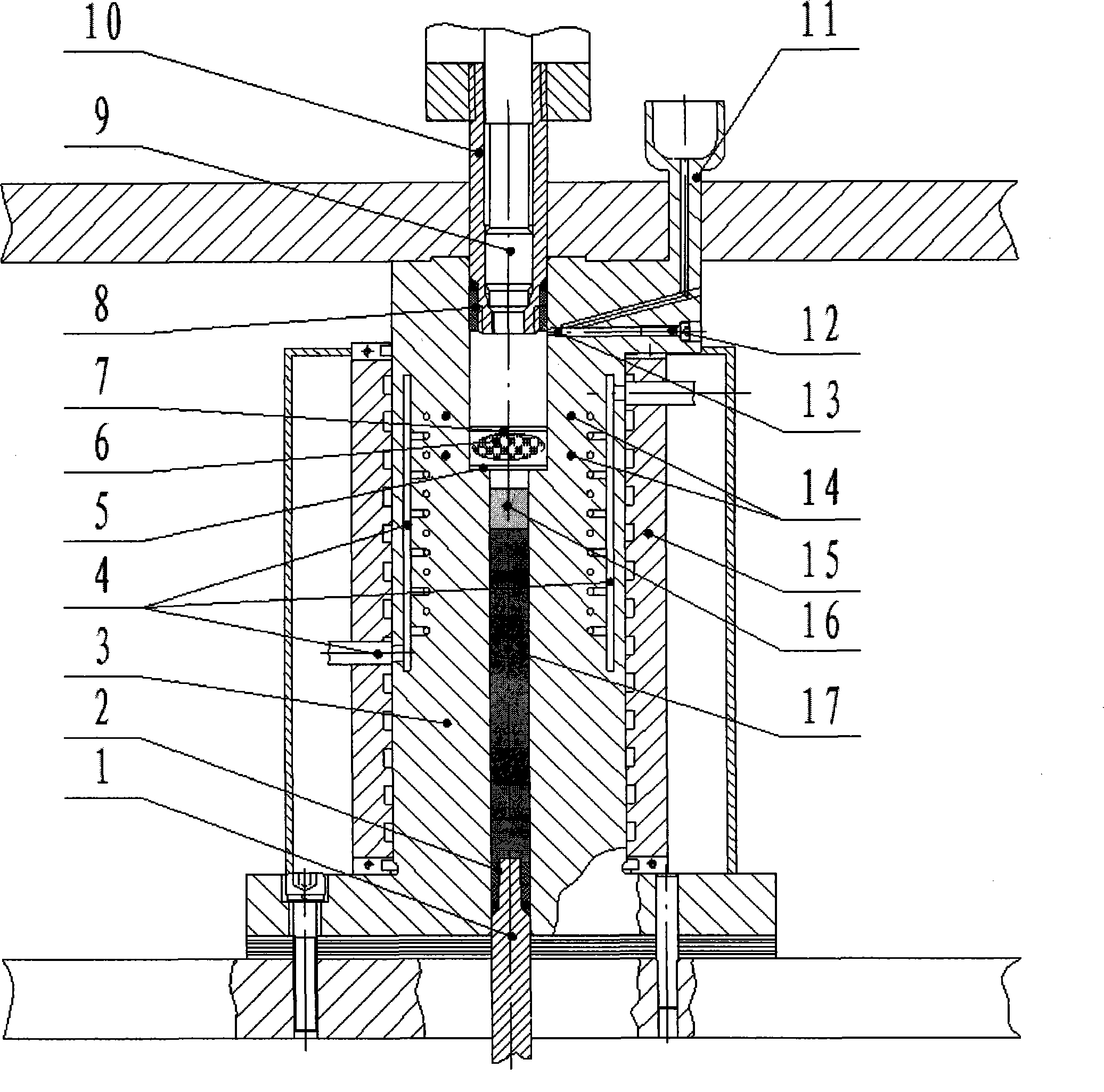

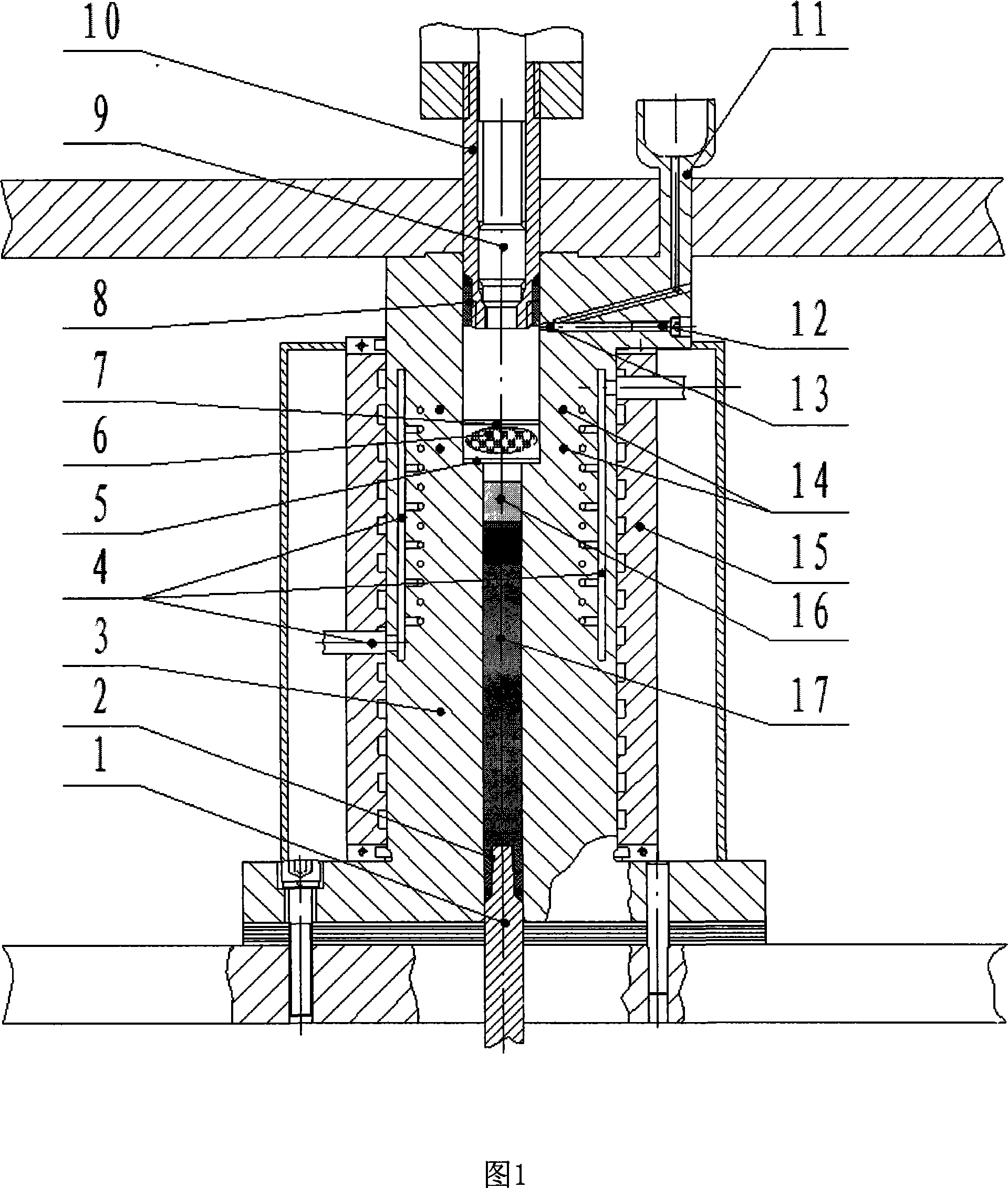

[0023] As shown in Figure 1, the test device of the present invention consists of pressure transmission medium mercury 17, sealing liquid 16, sample chamber, pressure vessel 3, pressurization system, heating and cooling system, pressure sensor 9, displacement sensor, thermocouple 14 and data processing system composition. Inside the pressure vessel 3 is a sample chamber, which consists of two chambers. The lower cavity has sufficient storage space for the pressure transmission medium mercury 17 and the sealing liquid 16 for sealing the mercury. Drill an outlet hole 13 on one side of the upper cavity, and connect the outlet pipe 11 outside, and the opening and closing of the outlet hole 13 is controlled by a switch valve 12 . A thin spacer is welded at the steps of the upper chamber and the lower chamber as the lower spacer 5, and the piece is full of small holes, which are used to hold the sample to be tested and allow the liquid to pass through; after the sample is put in, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com