Grating and its backlight module

A backlight module and grating technology, applied in diffraction grating, optics, optical components, etc., can solve problems such as reducing the utilization rate of light energy of liquid crystal displays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

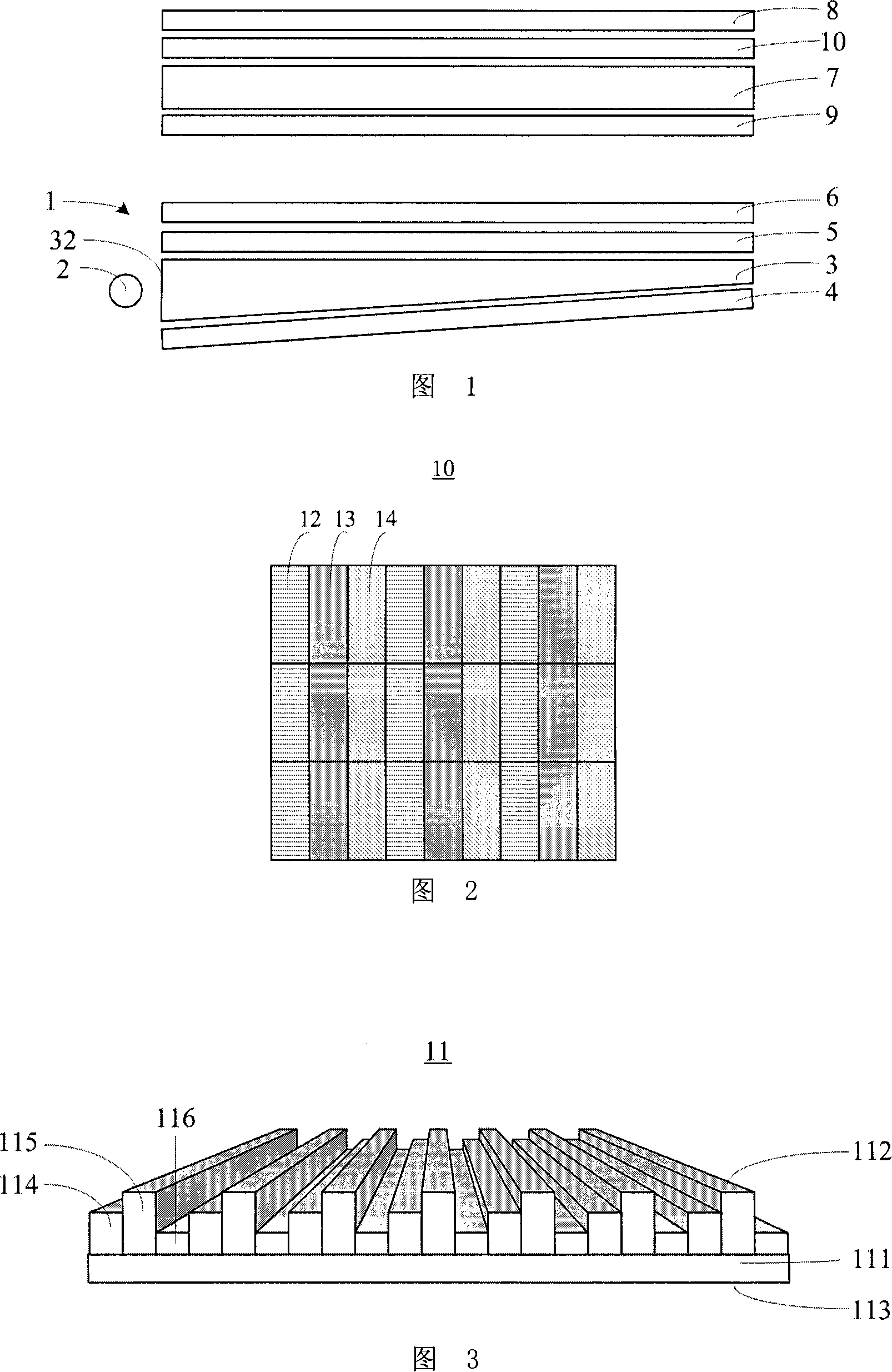

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

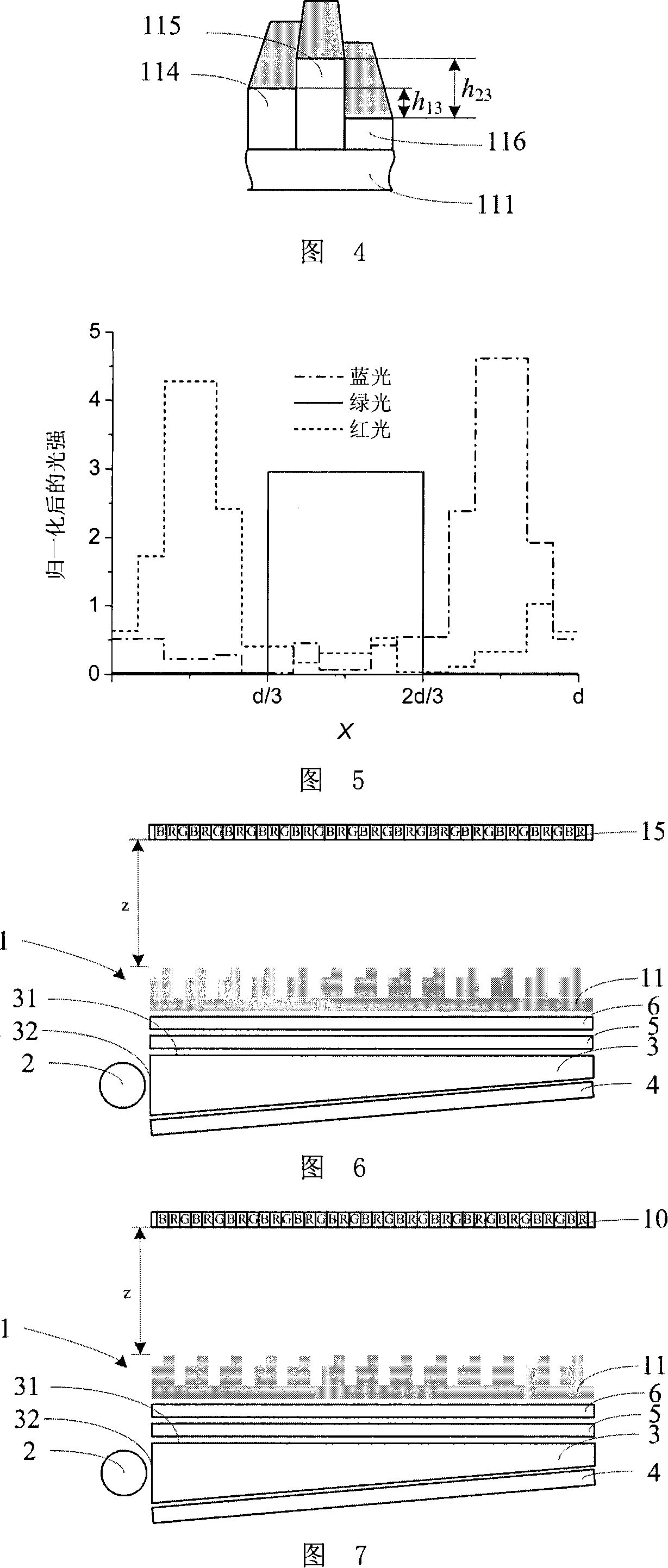

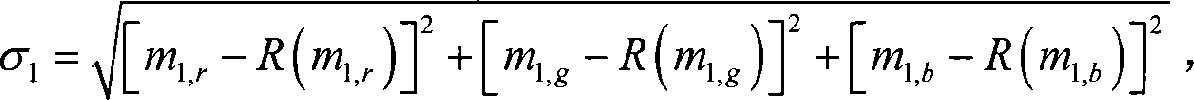

[0031] FIG. 3 is a three-dimensional schematic view of the grating 11 according to the first embodiment of the present invention. The grating 11 includes a base material portion 111 and a light emitting surface 112 . The base includes a light-incident surface 113 and a side surface connecting the light-incident surface 113 and the light-exit surface 112 . The grating structure is an equal-period grating, and the light-emitting surface 112 is a stepped structure, wherein the widths of the steps 114, 115, and 116 are the same. The grating 11 utilizes the fractional Taber effect.

[0032] Assuming n=1.52, the wavelengths of the three kinds of light incident at the same time during operation are λ b = 0.45 μm, λ g = 0.54 μm, λ r =0.63μm, then the heights of the three steps are h 1 = C + 2.06 μm, h 2 = C + 3.76 μm, h 3 =C μm, wherein C is any positiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com