DLP zooming projection lens

A technology of projection lens and zoom group, applied in the field of zoom projection lens, can solve the problems of strict processing and assembling requirements of aspherical lenses, low processing efficiency and yield, adverse production efficiency, etc., so as to improve the simplicity of processing and assembly, The effect of easy focusing and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

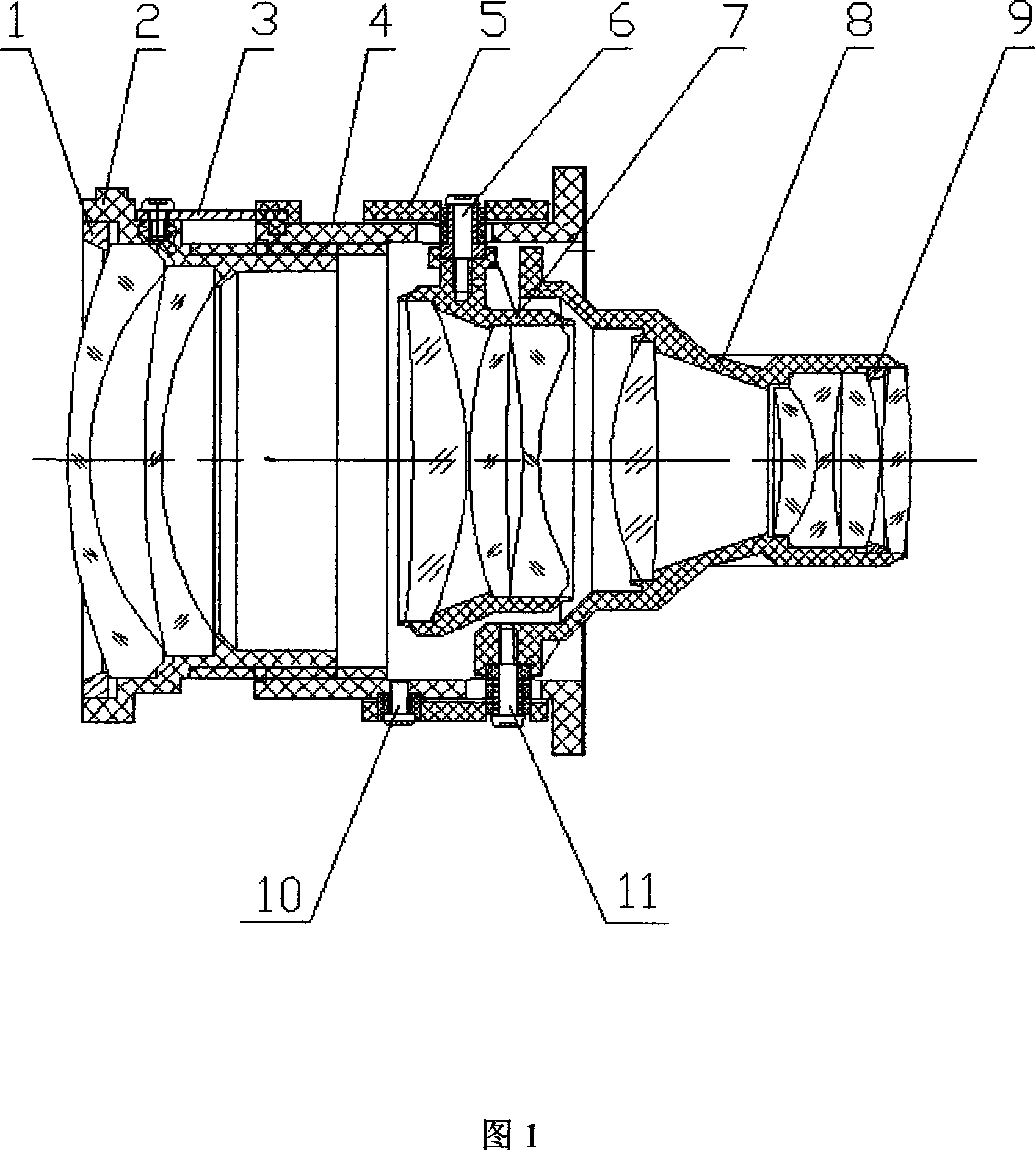

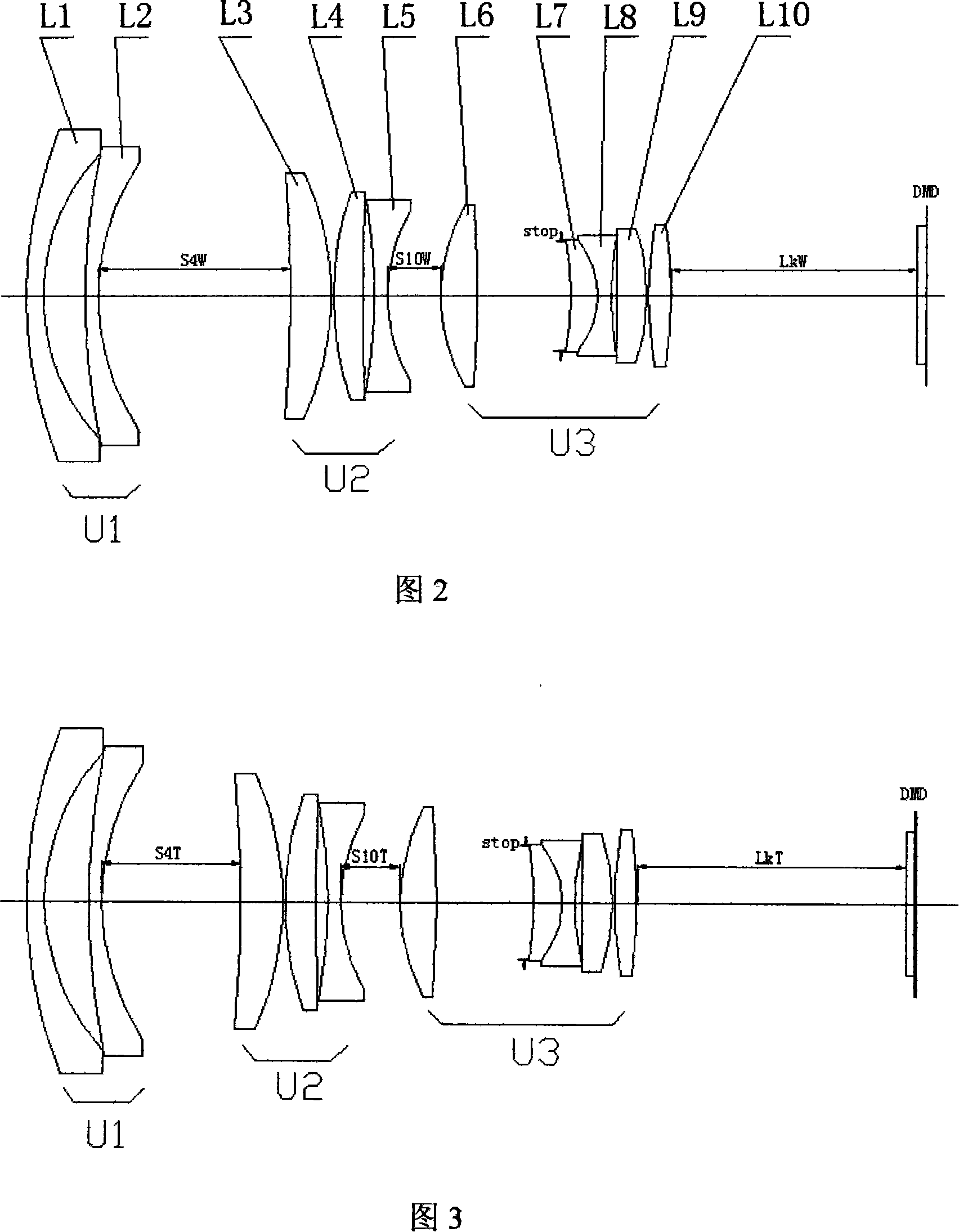

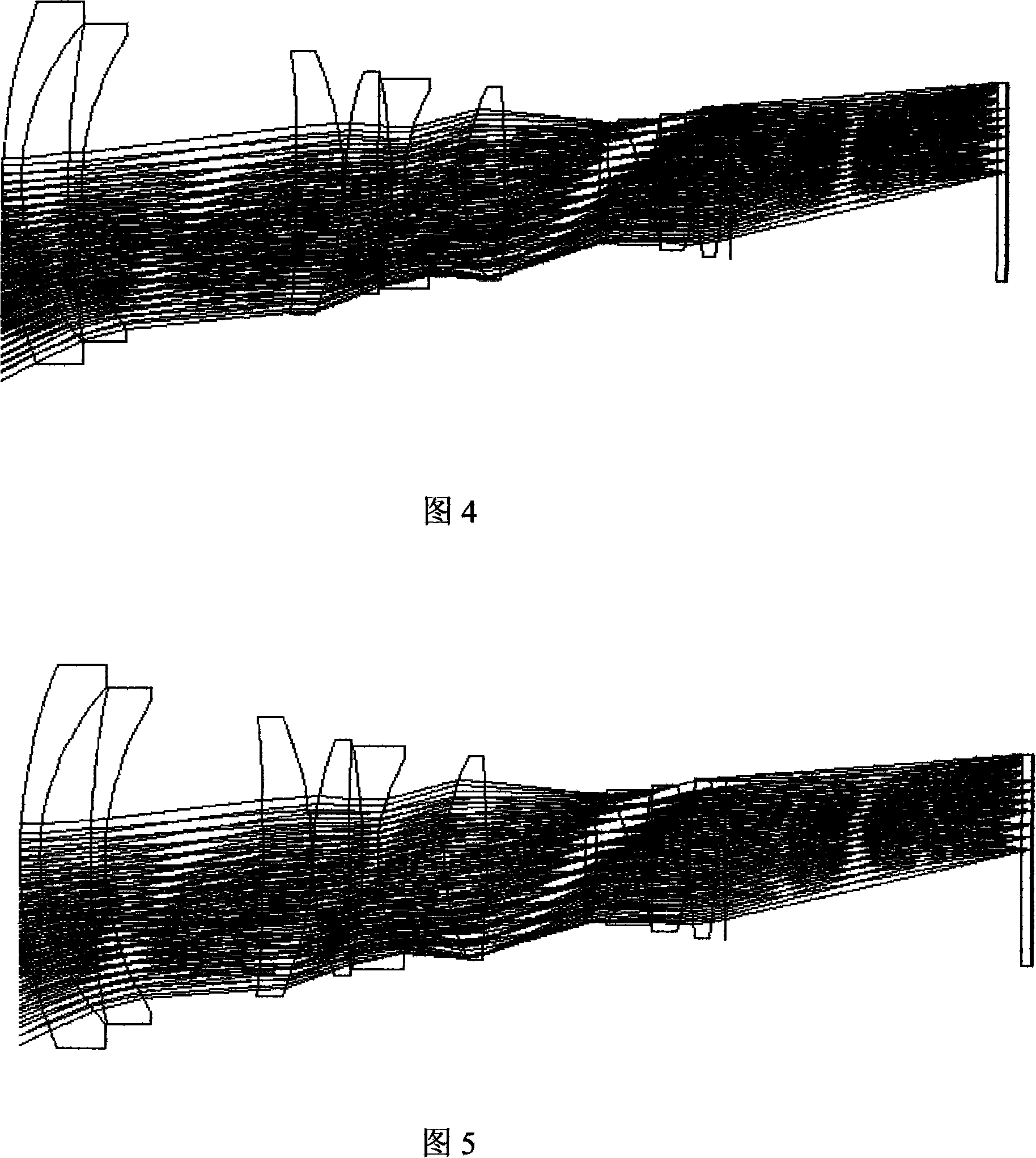

[0033] Referring to Fig. 1, Fig. 2 and Fig. 3, the zoom projection lens of the present invention, the main components include a pressure ring 1, a focusing lens barrel 2, a focusing stopper 3, a guide cylinder 4, a curved cylinder 5, a roller guide pin 6, Zooming lens barrel 7, compensating lens barrel 8, spacer 9, roller guide nail 10, roller guide nail 11 and lenses L1-L10 of the optical system, wherein the focusing lens barrel 2 is connected with the guide cylinder 4 through a multi-threaded thread, and its rotation The angle is controlled by the focus limiter 3; the guide cylinder 4 is covered with a curve cylinder 5, and the zoom lens barrel 7 and the compensation lens barrel 8 are respectively connected through the roller guide nail 6 and the roller guide nail 11, and the curve cylinder 5 is rotated. The roller guide nails can be moved along their respective curved grooves, and drive the zoom lens barrel 7 and the compensation lens barrel 8 to move. The role of the roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com