Automobile production line sling and regulating method thereof

A technology of automobile production line and spreader, which is applied in the direction of load hanging components, transportation and packaging, etc., which can solve the problems of reduced operability, reduced equipment utilization, and reduced efficiency, so as to reduce adjustment working time and reduce equipment investment costs , Improve the effect of market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

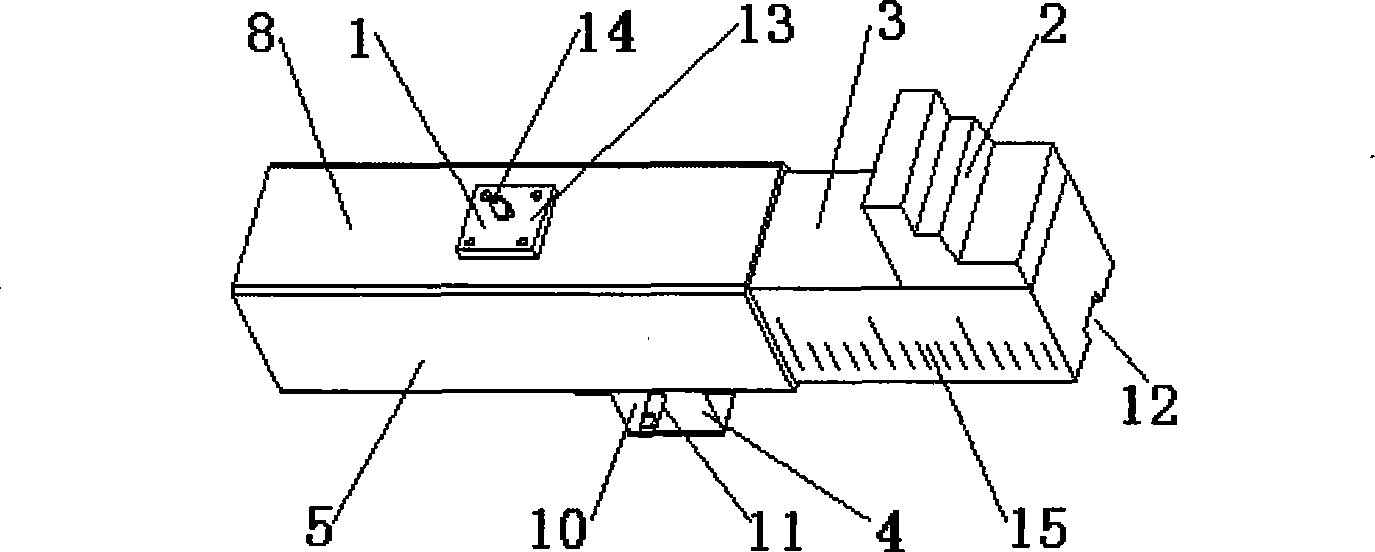

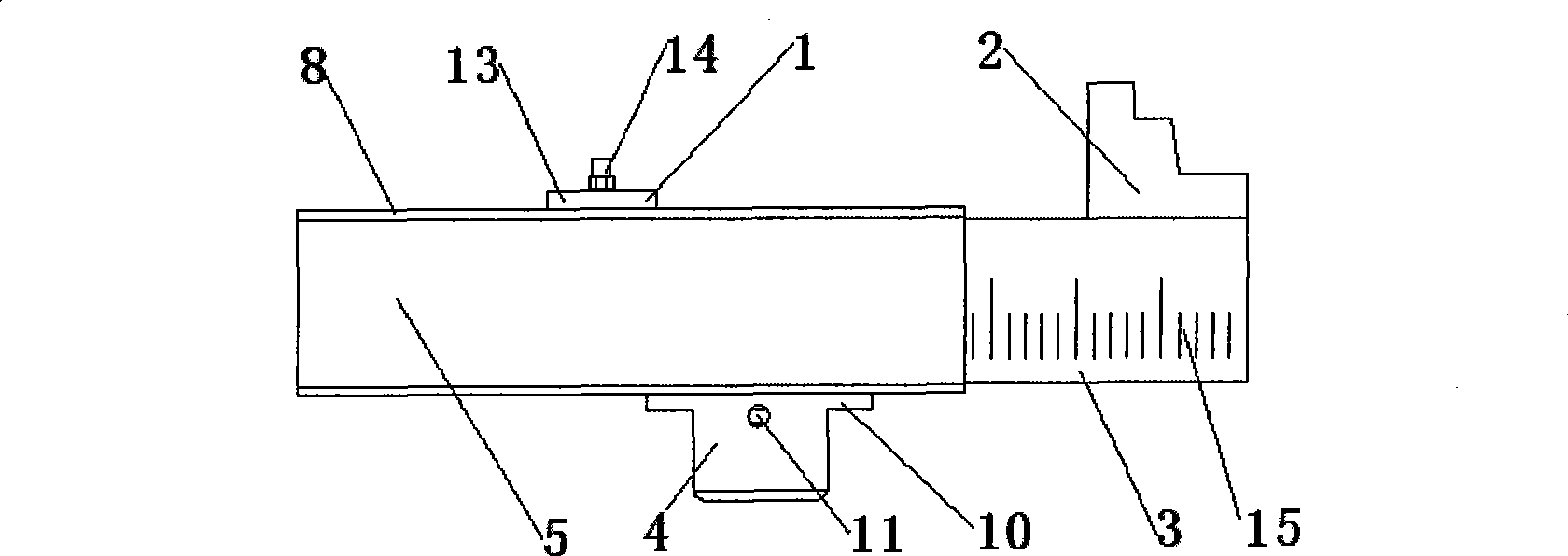

[0031] Such as figure 1 and figure 2 As shown, on the basis of the above-mentioned technical solution, the cross-sectional shape of the matching surface of the supporting arm fixing frame 5 and the movable supporting arm 3 using clearance fit according to the present invention is rectangular. The movable support arm 3 is inserted into the rectangular hole of the support arm fixed mount 5 and forms a clearance fit. The movable support arm 3 can be freely expanded and contracted in the rectangular hole of the supported arm fixed mount 5, and will not rotate during the telescopic process, so that the support arm The position of the block 2 on the straight line of motion will not change due to movement, ensuring that it can hold up the vehicle body reliably.

Embodiment 2

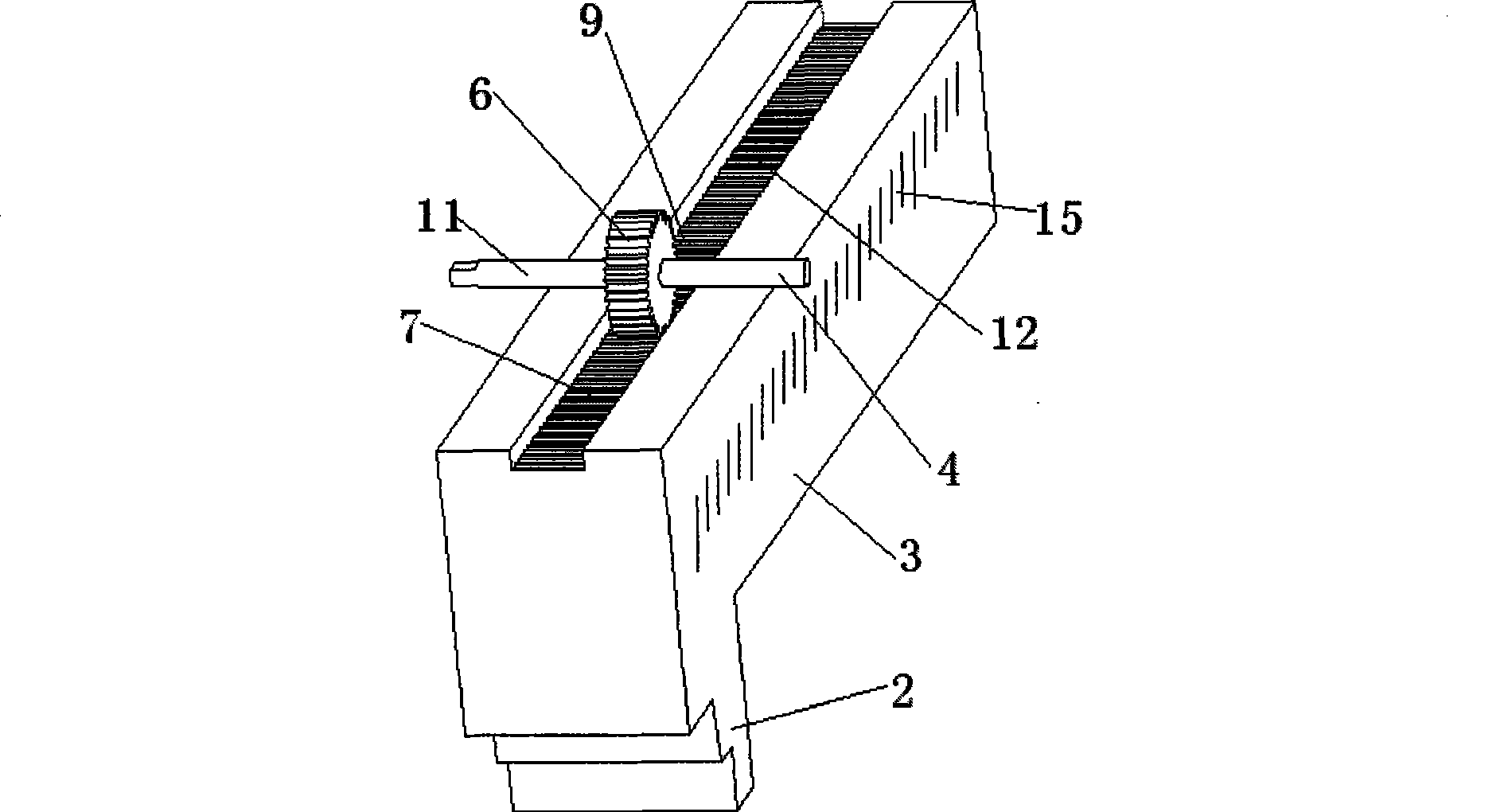

[0033] Such as figure 2As shown, on the basis of Embodiment 1, the rear transverse boom 8 of the present invention is provided with a stroke adjuster 4, and the stroke adjuster 4 is between the bracket arm fixing frame 5 and the movable bracket arm 3 A rack and pinion transmission mechanism 9 is provided, and the transmission direction of the rack and pinion transmission mechanism 9 is to make the movable support arm 3 stretch out or retract on the support arm fixed frame 5 . The rack and pinion transmission mechanism 9 is used to adjust the position of the movable support arm 3, which is convenient to operate, labor-saving, easy to control, accurate in positioning, and the structure occupies a small space.

Embodiment 3

[0035] Such as figure 2 As shown, the structure of the rack and pinion transmission mechanism 9 described in the above embodiment is: a rack 7 is set on the body of the movable bracket 3, a gear 6 is set on the bracket 5 of the bracket, and the gear 6 passes through The gear adjustment shaft 11 is supported by the stroke adjuster bracket 10 provided on the stroke adjuster 4, and the gear 6 and the rack 7 are meshed with each other. This setting scheme mainly considers the support of the gear 6 conveniently, and it is also convenient to use the gear 6 to carry out the adjustment operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com