Super-hydrophobic high-density polyethylene film preparation method

A high-density polyethylene and super-hydrophobic technology is applied in the field of preparing super-hydrophobic high-density polyethylene films, which can solve the problems of expensive materials and difficult industrialization, and achieve stable super-hydrophobic properties, good reproducibility and simple operation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

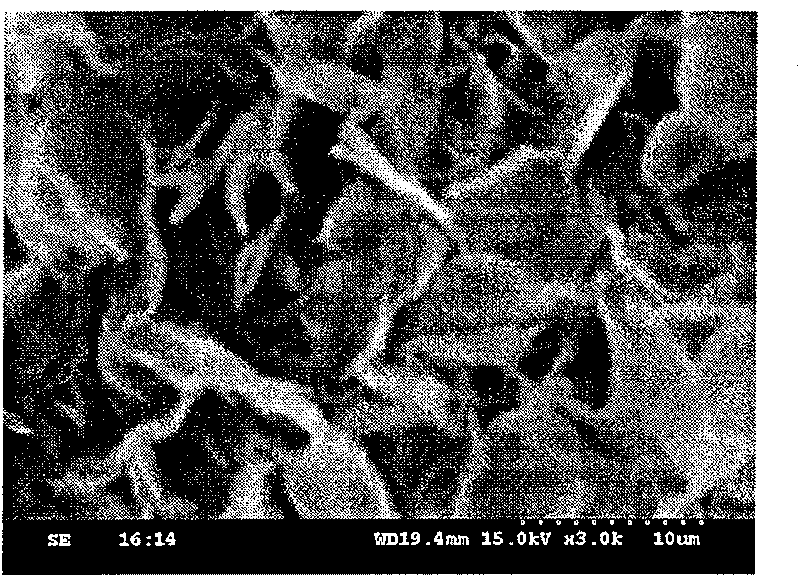

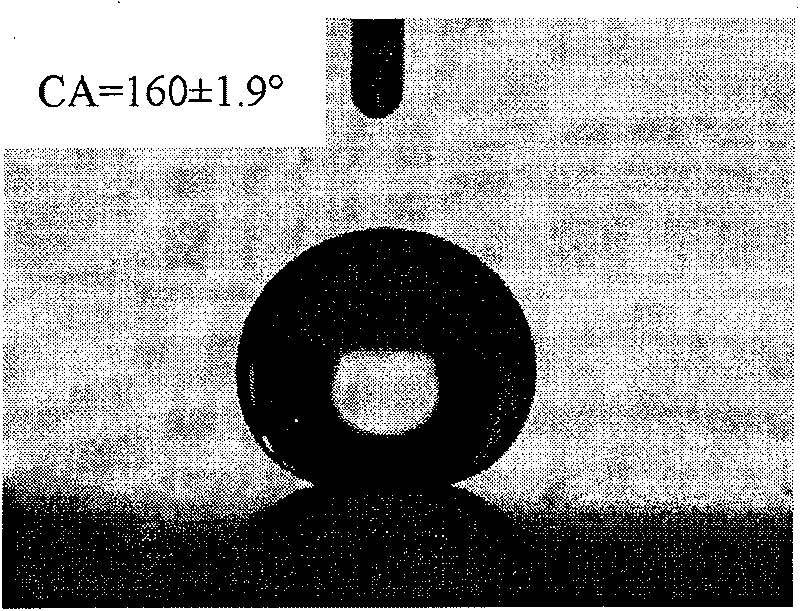

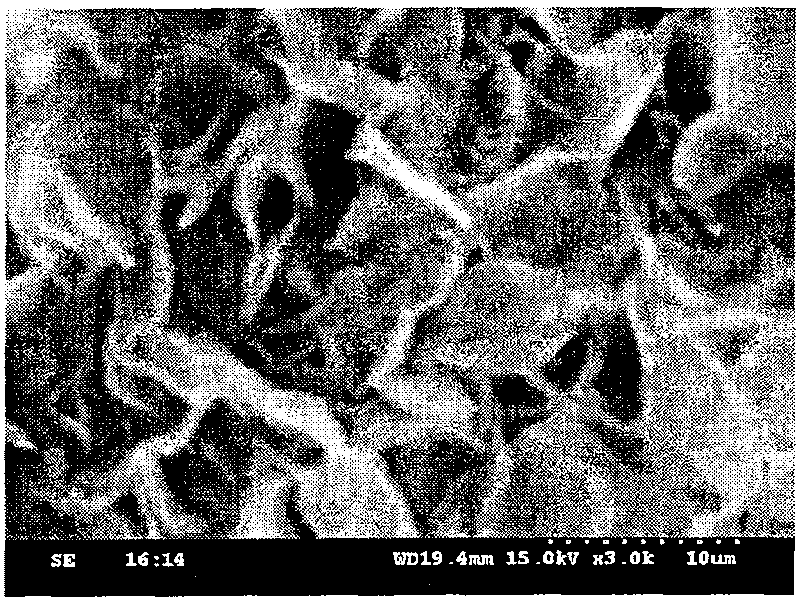

[0018] First, weigh 0.3 g of high-density polyethylene particles and dissolve them in 30 ml of xylene at 120 ° C to form a high-density polyethylene solution with a concentration of 10 mg / ml; then add 3 ml of absolute ethanol to the high-density polyethylene solution; Spread the high-density polyethylene solution added with ethanol on the glass substrate, and dry it for 10 hours at a relative humidity of 75% and a temperature of 5°C. The resulting white film is a superhydrophobic high-density polyethylene film. see figure 1 and figure 2 , tested the wettability of the film surface with OCA20 contact angle tester, the result showed that the contact angle between the surface and water was 160±1.9°. The surface morphology of the film was observed with a HITACHI S-3000N scanning electron microscope, and it was found that the film was composed of numerous irregular leaf-shaped high-density polyethylene sheets.

Embodiment 2

[0020] First, take 0.3 g of high-density polyethylene particles and dissolve them in 30 ml of xylene at 100° C. to form a high-density polyethylene solution with a concentration of 10 mg / ml; then add 3 ml of 95% ethanol to the high-density polyethylene solution; The high-density polyethylene solution added with 95% ethanol is flowed on the ceramic substrate by casting method, and dried for 8 hours in an environment with a relative humidity of 60% and a temperature of 25°C, and the obtained white film is superhydrophobic high-density polyethylene. vinyl film. The wettability of the surface of the film was tested with an OCA20 contact angle tester, and the result showed that the contact angle between the surface and water was 150±1.9°. The surface morphology of the film was observed with a HITACHI S-3000N scanning electron microscope, and it was found that the film was composed of numerous irregular leaf-shaped high-density polyethylene sheets.

Embodiment 3

[0022] First, weigh 0.03 g of high-density polyethylene particles and dissolve them in 30 ml of xylene at 140 ° C to form a high-density polyethylene solution with a concentration of 1 mg / ml; then add 0.3 ml of absolute ethanol to the high-density polyethylene solution; The high-density polyethylene solution added with ethanol is flowed on the metal substrate by the casting method, and dried for 10 hours at a relative humidity of 70% and a temperature of 20 ° C. The resulting white film is a super-hydrophobic high-density polyethylene film. The wettability of the surface of the film was tested with an OCA20 contact angle tester, and the result showed that the contact angle between the surface and water was 155±1.9°. The surface morphology of the film was observed with a HITACHI S-3000N scanning electron microscope, and it was found that the film was composed of numerous irregular leaf-shaped high-density polyethylene sheets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com