Electrochemical cell stack with frame elements

A battery pack, electrochemical technology, applied in the field of electrochemical or electrolytic battery pack, can solve the problem of reducing the effective depth of the distribution channel and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

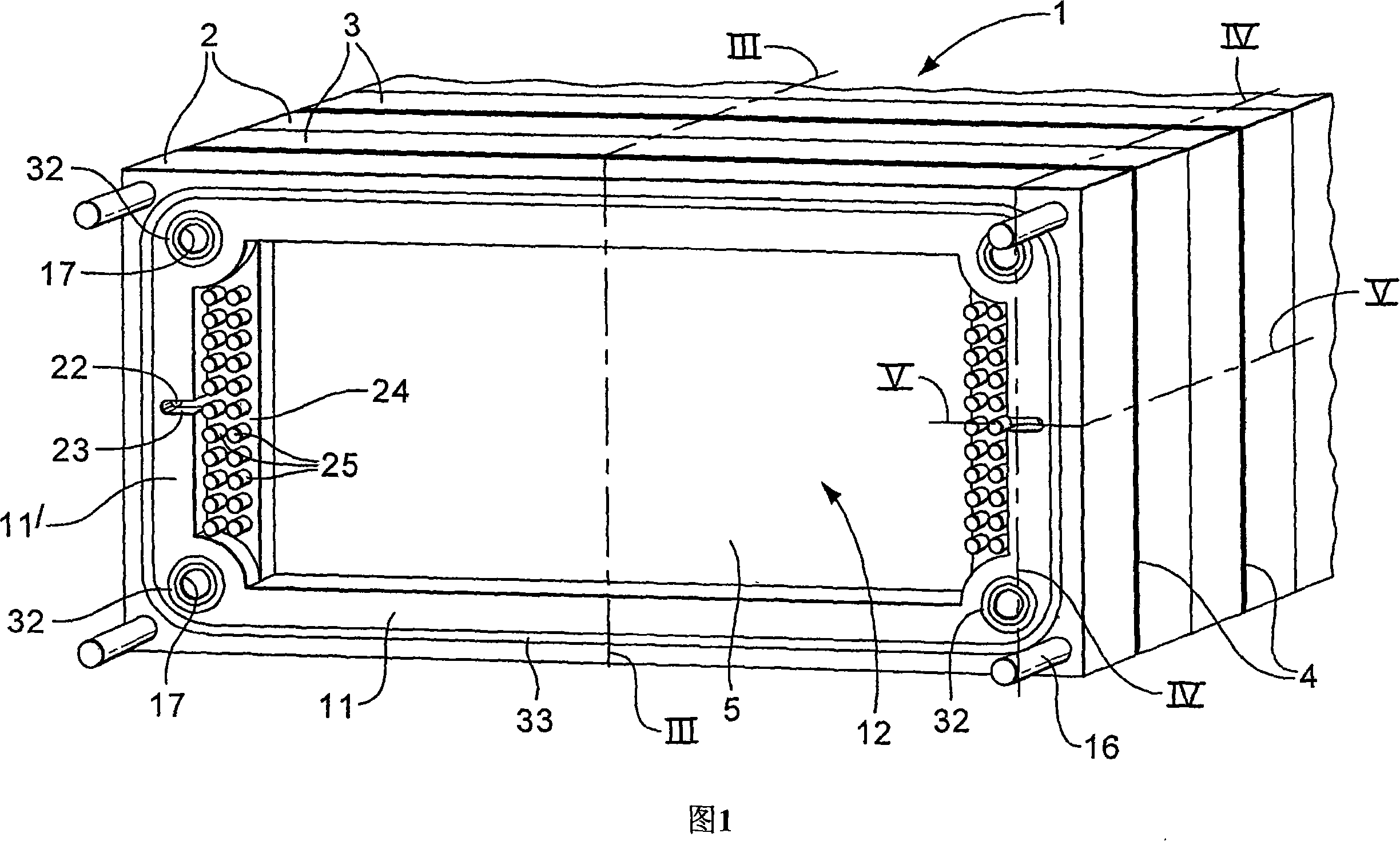

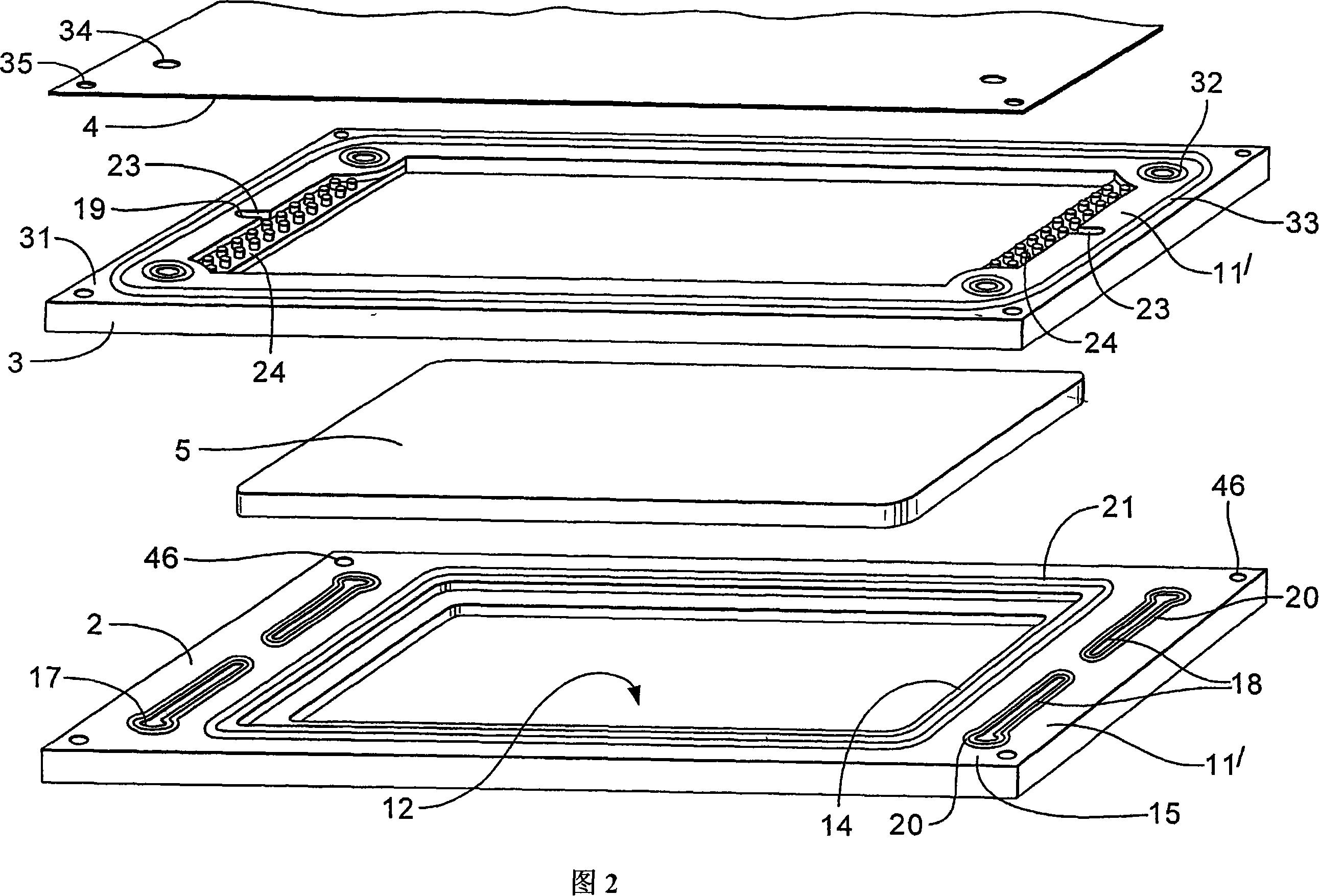

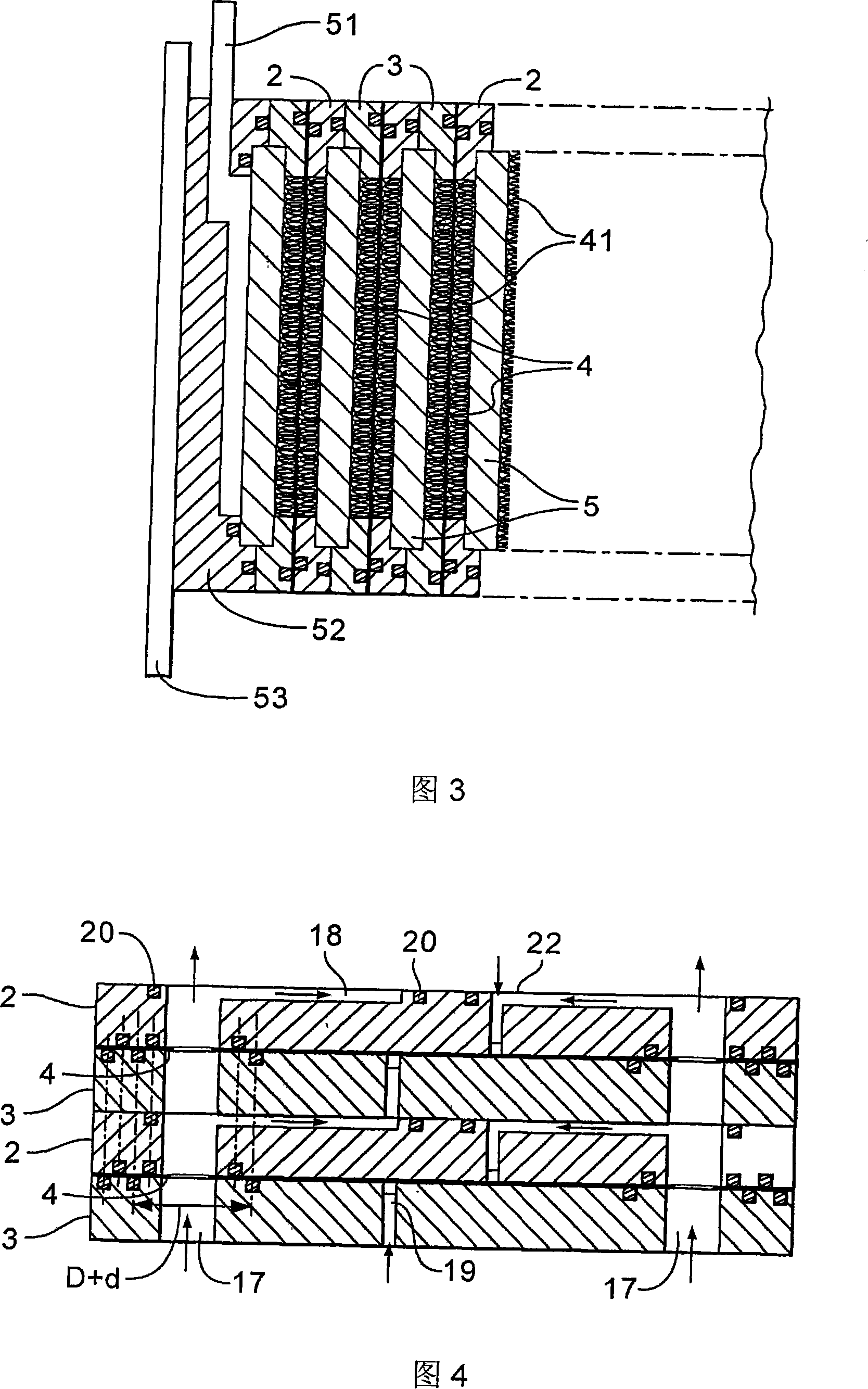

[0033] Referring to the illustration, a redox fuel cell stack 1 includes a plurality of half-cell frames 2, 3 which are basically the same although there are some differences between them. These frames are made of molded polymer. Semi-permeable membranes 4 and graphite electrode plates 5 (made of polymer filled with large quantities of graphite powder or chips) are placed alternately between the frames. When used, the electrodes are used as bipolar electrodes for different reactants and reactions on either side. When the reaction occurs, the membrane divides the reactants evenly and allows selected ions and electrons to pass through. The present invention is concerned with the actual arrangement of the battery components, but it should be noted that a complete electrochemical cell is located between each pair of electrodes and includes a separator and a half-cell cavity consisting of the cavities described below .

[0034] Both frames 2 , 3 are rectangular with edges 11 sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com